Guide bar arrangement of warp knitting machine

A warp knitting machine and bar technology, which is applied in the field of bar devices, can solve the problems of increasing the width and speed of the driving power machine, increasing the mass, and accelerating, and achieves the effect of reducing the risk of wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

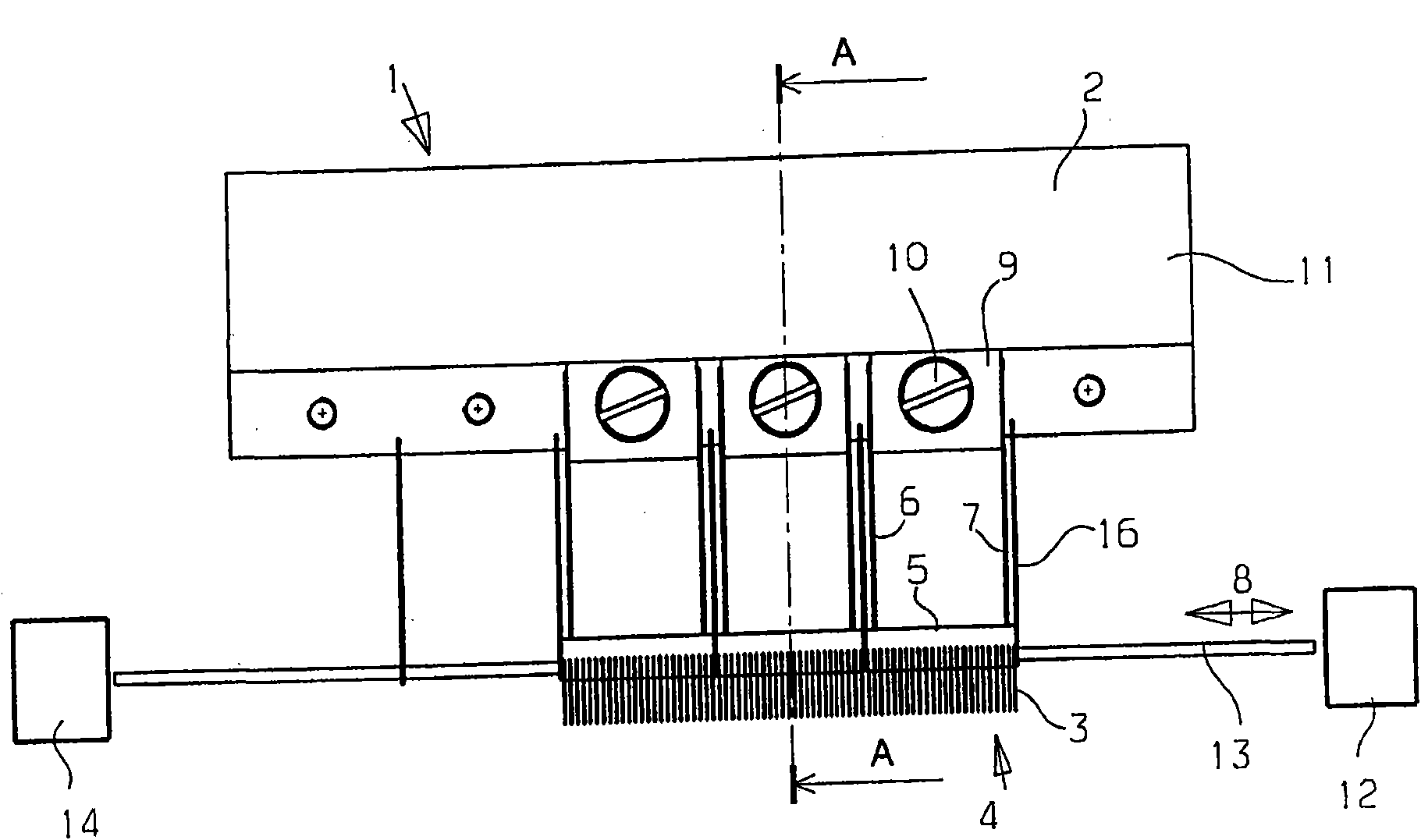

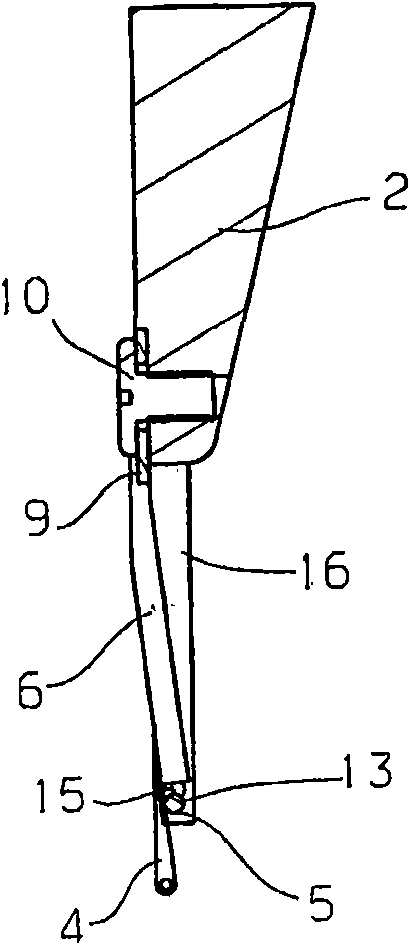

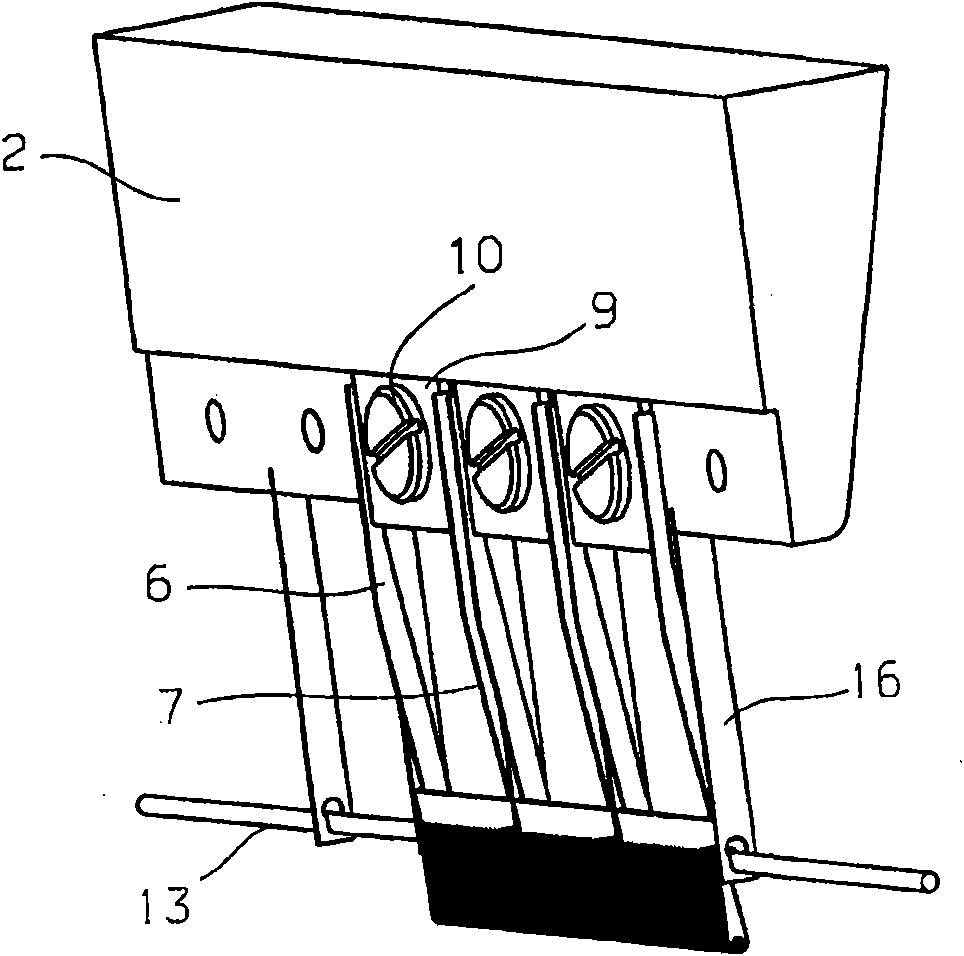

[0033] figure 1 It is a schematic diagram of a bar device 1 , which has a bar 2 and a plurality of guide needles 3 . A plurality of guide needles 3 form fan-shaped plates 4 respectively. Each sector plate 4 has a bracket 5 . The distance of the brackets 5 along the direction of successive arrangement of the guide needles 3 is, for example, 2 inches. It then has, for example, 48 guide needles 3 .

[0034] The bracket 5 is fixed on the comb bar 2 through two connection mechanisms 6,7. The connecting means 6 , 7 allow the carriage 5 and thus the sector plate 4 with the guide needles 3 arranged therein to be moved relative to the bar 2 in the traverse direction 8 , ie in the direction of the successive arrangement of the guide needles 3 . The connecting means 6 , 7 are arranged on a fastening part 9 which is fastened to the bar 2 by means of screws 10 . A threaded hole 11 is provided on the bar 2 for each fastening element 9 .

[0035] A drive mechanism 12 is provided in ord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com