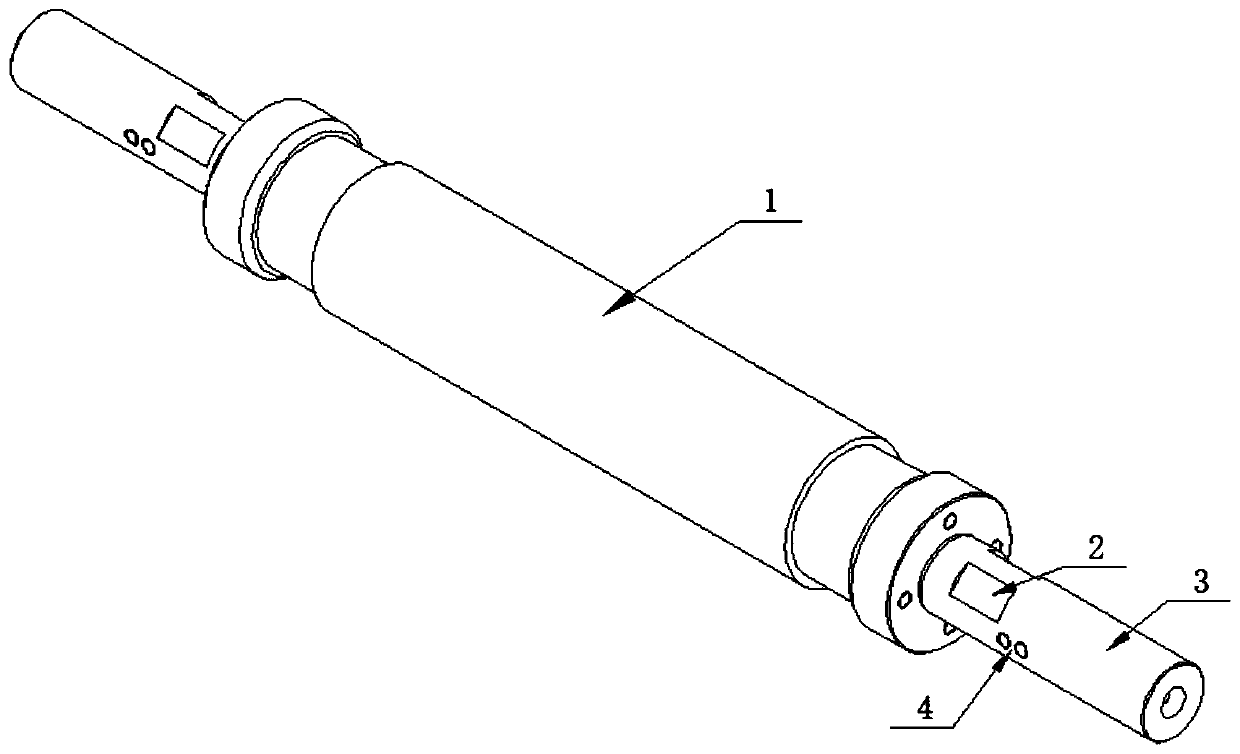

Combined die cutting tool

A combined type and cutting tool technology, which is applied in metal processing and other directions, can solve problems such as insufficient contact of fittings or bottom rollers, failure to meet the installation requirements of cutter rollers, and inability to adjust the position of transmission gears, so as to reduce the risk of equipment wear and improve reliability. Operability and the effect of improving the efficiency of installation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment 1 belongs to the above-mentioned situation one.

[0043] Install:

[0044] 1. Install the knife adjuster on the cutter body, use the screw to pass through the countersunk hole on the knife adjuster, and fix it on the cutter body;

[0045] 2. Install the pin on the cutter gear in advance, then install the cutter gear on the cutter body, align the pin with the pin adjustment hole on the cutter adjuster, and then overlap the cutter gear with the cutter adjuster, and adjust the two holes through the pin adjustment hole. The screw on the side limits the pin and locks it to the middle position for adjustment;

[0046]3. Install the spring and retaining ring on the shaft head so that the end face of the retaining ring meets the tool gear to prevent slipping.

[0047] adjust:

[0048] After installing the tool to the equipment station as required, when the size needs to be adjusted, the size adjustment function can be realized by adjusting the screws in the l...

Embodiment 2

[0050] Embodiment 2 belongs to above-mentioned situation two

[0051] Install:

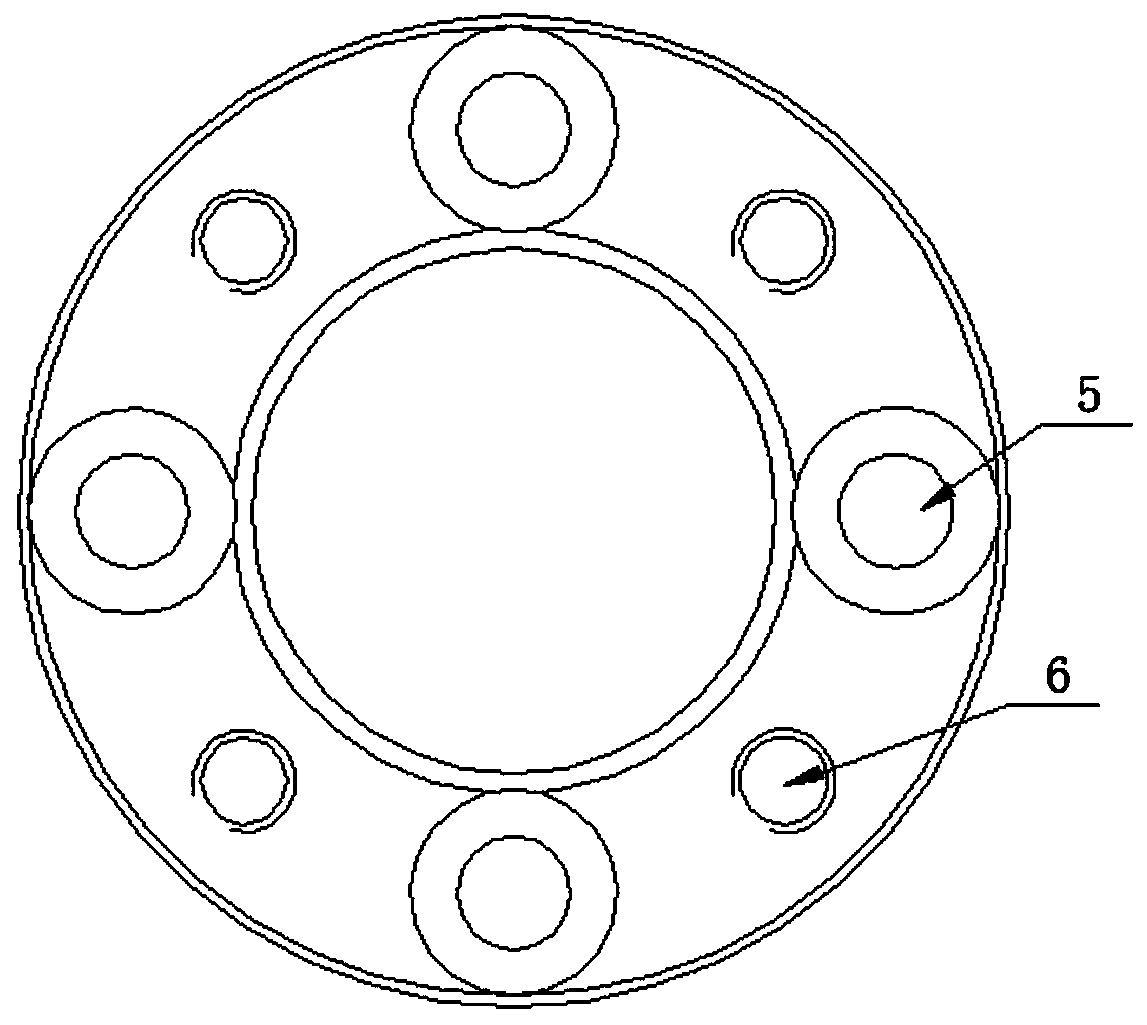

[0052] 1. First, install the interdental pad on the cutter body through screws;

[0053] 2. Install the pin on the cutter gear in advance, then install the cutter gear on the cutter body, with the pin facing the outside, and use the other side of the cutter gear to coincide with the interdental pad;

[0054] 3. Install the knife adjuster to the cutter body. When installing, pay attention to align the pin adjustment hole on the knife adjuster with the pin. After the knife adjuster coincides with the cutter gear, the pin is limited by the screws on both sides of the pin adjustment hole. , and lock it to the middle position for adjustment;

[0055] 4. Turn the knife adjuster so that the two locking screw holes on the top are aligned with the locking platform on the shaft head, and fix the knife adjuster at the shaft head by passing two screws through the locking screw holes.

[0056] adjust:

[0...

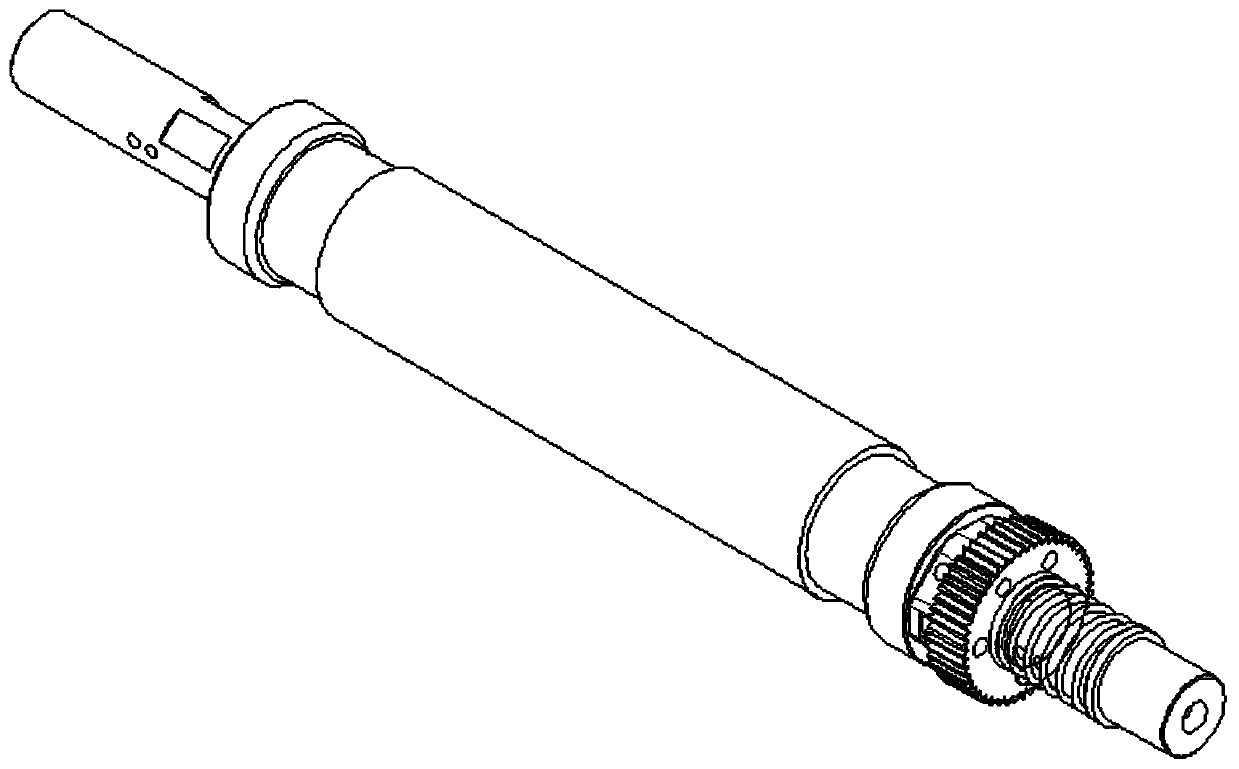

Embodiment 3

[0059] Embodiment 3 belongs to above-mentioned situation two

[0060] Install:

[0061] 1. First, install the interdental pad on the cutter body through screws;

[0062] 2. It is necessary to install and fasten the cutter gear, gasket and high-precision cutter adjuster with screws in advance;

[0063] 3. Install the installed cutter gear, gasket and high-precision cutter adjuster to the cutter body at the shaft head according to the direction shown in the drawing, so that the cutter gear and the interdental pad are overlapped;

[0064] 4. Use screws to install to the threaded holes of the cutter body through the mounting holes set on the outer edge of the high-precision cutter adjuster to fix it.

[0065] adjust:

[0066] After installing the tool to the equipment station as required, when the size needs to be adjusted, the size adjustment function can be realized by adjusting the size adjustment function of the high-precision knife adjuster.

[0067] The high-precision kn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com