Spiral vertical axis wind turbine blade for wind power generation and machining method

A wind turbine blade and processing method technology, which is applied to wind turbines, wind turbines at right angles to the wind direction, motors, etc., can solve the problems of low utilization rate of wind energy, poor self-starting ability, unclear utilization of wind energy, etc., so as to improve wind energy. The effect of using scale to solve the problem of complex surface processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

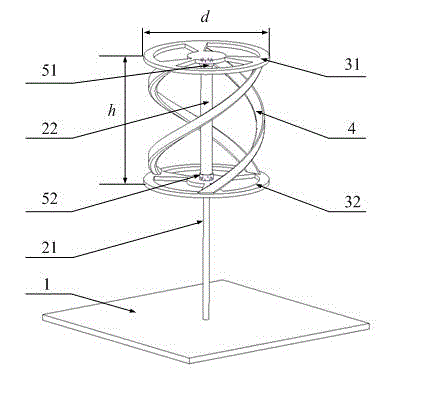

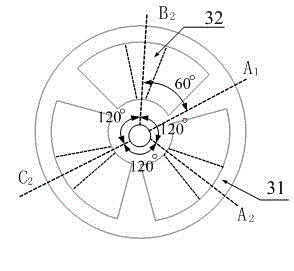

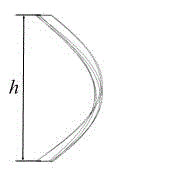

[0030] Take three blades as an example, see attached figure 1 . The vertical axis spiral wind turbine of the present invention includes a base platform 1, a column 21 is welded above the center of the base platform, and two bearings 51 and 52 are respectively assembled on the upper part of the column 21 at a distance of h, and the outer rings of the two bearings cooperate with the bearing sleeve 22, and the bearing sleeve 22 and the upper and lower disc supports 31,32 are fixed with screws, and the 4 ends of the three blades are respectively fixed on the upper and lower disc supports 31,32, and the blades 4 are evenly distributed around the column 21 circumferentially to form a wind wheel. The wind wheel realizes the absorption and conversion of wind energy.

[0031] The foundation platform 1 can be a reinforced concrete platform, a steel plate, or a steel frame structure. During construction, the upper surface of the foundation platform 1 is required to be parallel to the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com