Belt wheel unit and belt wheel provided with unit and belt driven structure

A technology of belt transmission and pulleys, which is applied to transmission devices, components with teeth, belts/chains/gears, etc., which can solve problems such as belt heating, inability to achieve continuous speed change, and easy slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

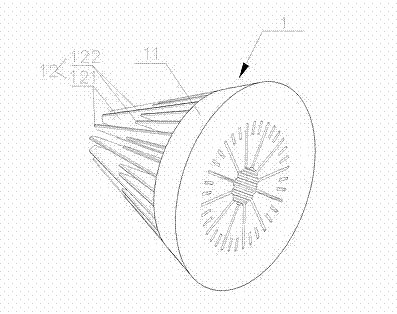

[0022] Depend on figure 1 As shown, the pulley unit 1 of the present invention is set on the pulley shaft 2 during assembly, and has a circular distribution with the axis of the pulley shaft 2 as the center line connected by the connecting part 11 and equidistant from the center line. Meshing teeth 12 with equal tooth thickness, the meshing teeth 12 are arranged at equal intervals, the tooth tops have the same slope relative to the axis of the pulley shaft 2, the minimum distance between the opposite end faces of two adjacent meshing teeth 12 is greater than the tooth thickness, and the pair of connected The purpose of the distance limitation between two meshing teeth 12 is to allow the meshing teeth of another pulley unit to be inserted between adjacent two meshing teeth 12, so as to realize the pulley structure in the second embodiment; the meshing teeth 12 are composed of The connection meshing teeth 121 connected to the pulley rotating shaft 2 by inserting the tooth bottom...

Embodiment 2

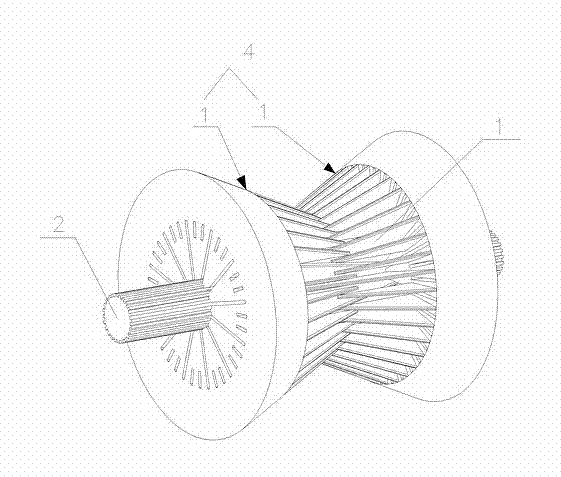

[0025] Depend on image 3 As shown, the pulley 4 of this embodiment is composed of two identical pulley units 1 connected to each other through the meshing teeth 12 of each pulley unit 1 , and each pulley unit 1 has a structure as described in the first embodiment.

Embodiment 3

[0027] Depend on Figure 4-Figure 6 As shown, this embodiment relates to a belt transmission structure, which is composed of two pulley shafts 2 arranged in parallel, a pulley 4 arranged on the pulley shaft 2 and a belt 3 sleeved on the pulley 4, wherein, The pulley 4 has the structure as described in the second embodiment.

[0028] The pulley rotating shaft 2 is provided with an engaging groove 21 parallel to the axis, and the connecting engaging teeth 121 of the pulley 4 are inserted into the engaging groove 21 to realize the axial rotational positioning of the pulley 4 and the pulley rotating shaft 2 .

[0029] The belt 3 has meshing parts 31 arranged at equal intervals. The meshing parts 31 are arranged on the belt body 32 and have an isosceles triangle cross-sectional shape. complementary angles. Driven by the rotation of the pulley rotating shaft 2 , the pulley 4 is inserted into the gaps between the pulley meshing teeth 12 one by one through the engaging portions 31 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com