Tunnel lining crack width measuring method and device

A technology of crack width and measurement method, which is applied in measurement devices, optical devices, image data processing, etc., can solve the problems of cumbersome hand-held contact acquisition process, random shooting distance, and complicated image preprocessing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

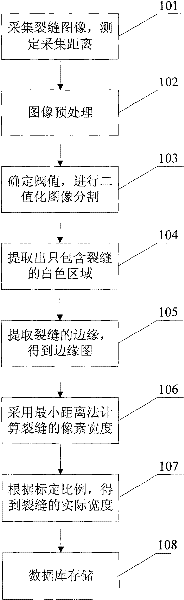

[0070] Such as figure 1 As shown, a method for measuring the crack width of a tunnel lining includes the following steps:

[0071] Step 101, collecting images of cracks by a digital camera, and measuring the collection distance by a laser rangefinder;

[0072] Step 102, select an area to be measured on the collected image, and convert the selected area image into a grayscale image;

[0073] Step 103, determining the threshold value of the grayscale image selected in step 102, and performing binarized image segmentation to obtain the target area;

[0074] Step 104, extracting a white area containing only cracks in the target area;

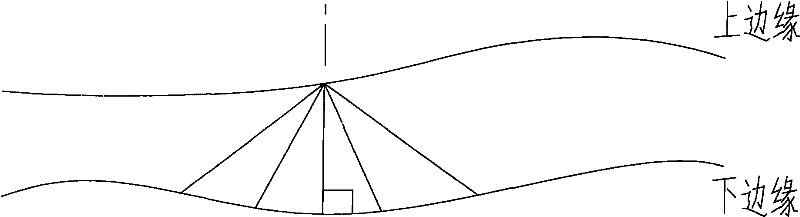

[0075] Step 105, using the sub-pixel method to extract the edge of the crack to obtain a sub-pixel level edge map;

[0076] Step 106, using the minimum distance method to calculate the pixel width of the crack;

[0077] Step 107, calculate the actual width of the crack according to the calibration ratio of the predetermined pixel actual size and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com