Method of desulfurizing molten iron

A processing method and technology for molten iron, applied in furnaces, lighting and heating equipment, stirring devices, etc., can solve the problem of not implementing desulfurization agent addition, and achieve the effects of preventing agglomeration, increasing collision, and improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

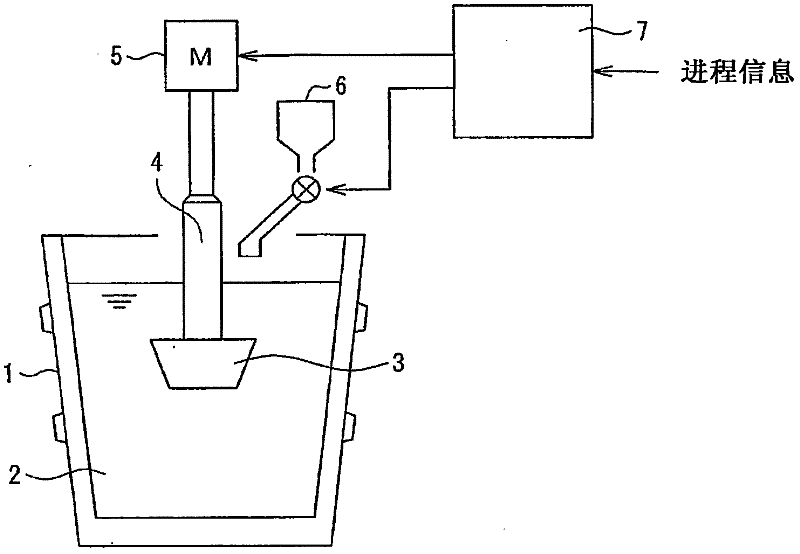

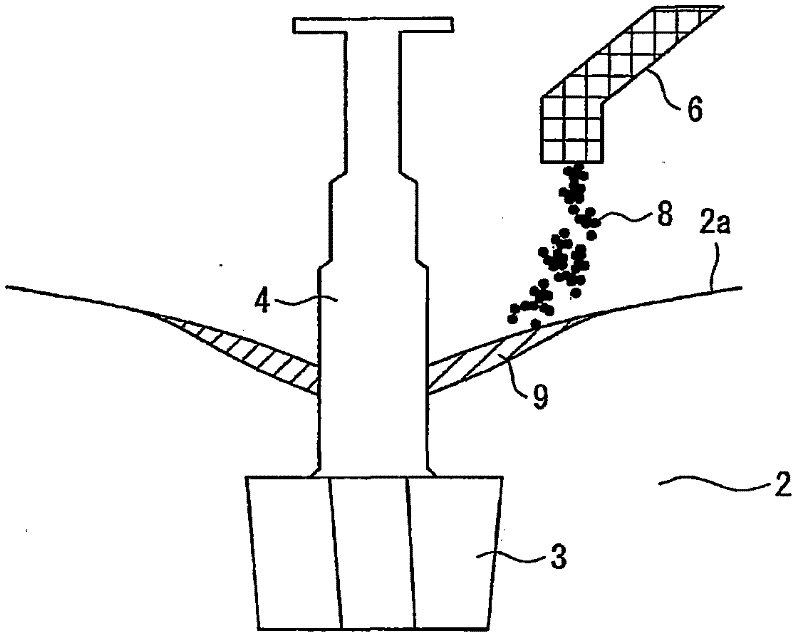

[0025] Next, a first embodiment of the present invention will be described with reference to the drawings. However, the present invention is not limited to the examples disclosed below. figure 1 It is a conceptual diagram showing the desulfurization treatment facility of molten iron in this embodiment. in addition, image 3 Expressed in figure 1 An example of the utilization state of the shown desulfurization treatment facilities.

[0026] (structure)

[0027] First, the device structure will be described. figure 1 Among them, the label 1 is the hot-metal ladle. Molten iron 2 is accommodated in the molten iron tank 1 . By inserting the impeller 3 into the molten iron tank 1 containing the molten iron 2 from above, the impeller 3 is immersed in the molten iron 2 . The impeller 3 is constituted by, for example, an impeller 3 with four blades (four-bladed: four leaves, cross-shaped: cross-shaped). The rotating shaft 4 of the impeller 3 is arranged with its shaft facing...

no. 2 approach

[0052] Next, a second embodiment will be described with reference to the drawings. In addition, the same code|symbol is attached|subjected and demonstrated about the apparatus etc. which are the same as said 1st Embodiment. In addition, similarly, it is not limited to the following examples.

[0053] The basic structure of this embodiment is the same as that of the above-mentioned first embodiment. However, there is a difference in the elevation control of the impeller 3 in the desulfurization process. Not described in the first embodiment, however, figure 1 The desulfurization treatment equipment of the present invention is equipped with an impeller elevating device (not shown) for elevating the impeller 3 . In the general lifting control of the impeller 3, the impeller 3 is lowered into the molten iron tank 1 before the desulfurization treatment to impregnate the impeller 3 into the molten iron 2, and then the height of the impeller 3 is kept constant during the desulfur...

Embodiment

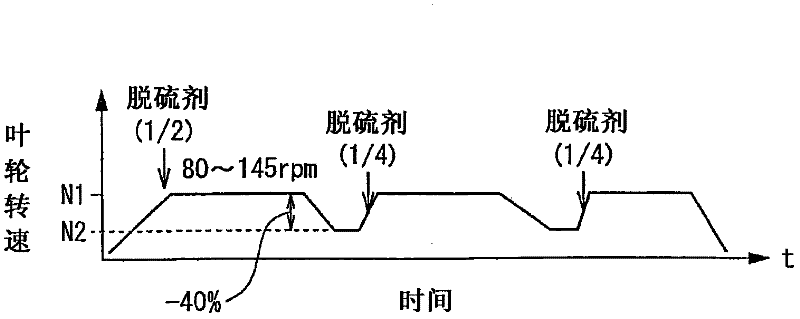

[0068] According to the following conditions, in the first embodiment ( figure 2 ), the second embodiment ( Figure 4 ) and comparative examples (with figure 2 The desulfurization agent is put into the mode, and the impeller speed is fixed in N1) for desulfurization treatment of molten iron. The height of the upper surface of the impeller under normal stirring is 100cm lower than the surface of the static molten iron.

[0069] ·molten iron

[0070] Composition before treatment: C: 4.3% by mass, S: 0.023% by mass (S 0 )

[0071] Capacity: 300 tons

[0072] ·Desulfurizer

[0073] Type: Lime

[0074] Consumption: 1500kg

[0075] · Processing time

[0076] Each treatment at speed N1: about 8 minutes

[0077] Each treatment at speed N2: about 2 minutes

[0078] The results obtained are as follows. S f is the S concentration of molten iron after desulfurization treatment.

[0079] The first embodiment: S removal rate ln(S 0 / S f ) = 2.1

[0080] ·Second embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com