Lifting valve structure for dirt discharging pipeline

A technology for sewage pipelines and valves, which is applied in the field of lifting valve structures for sewage pipelines, can solve the problems of heavy rainfall, full water operation, valve corrosion, etc., and achieves the effects of simple operation, compact layout and prevention of rupture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

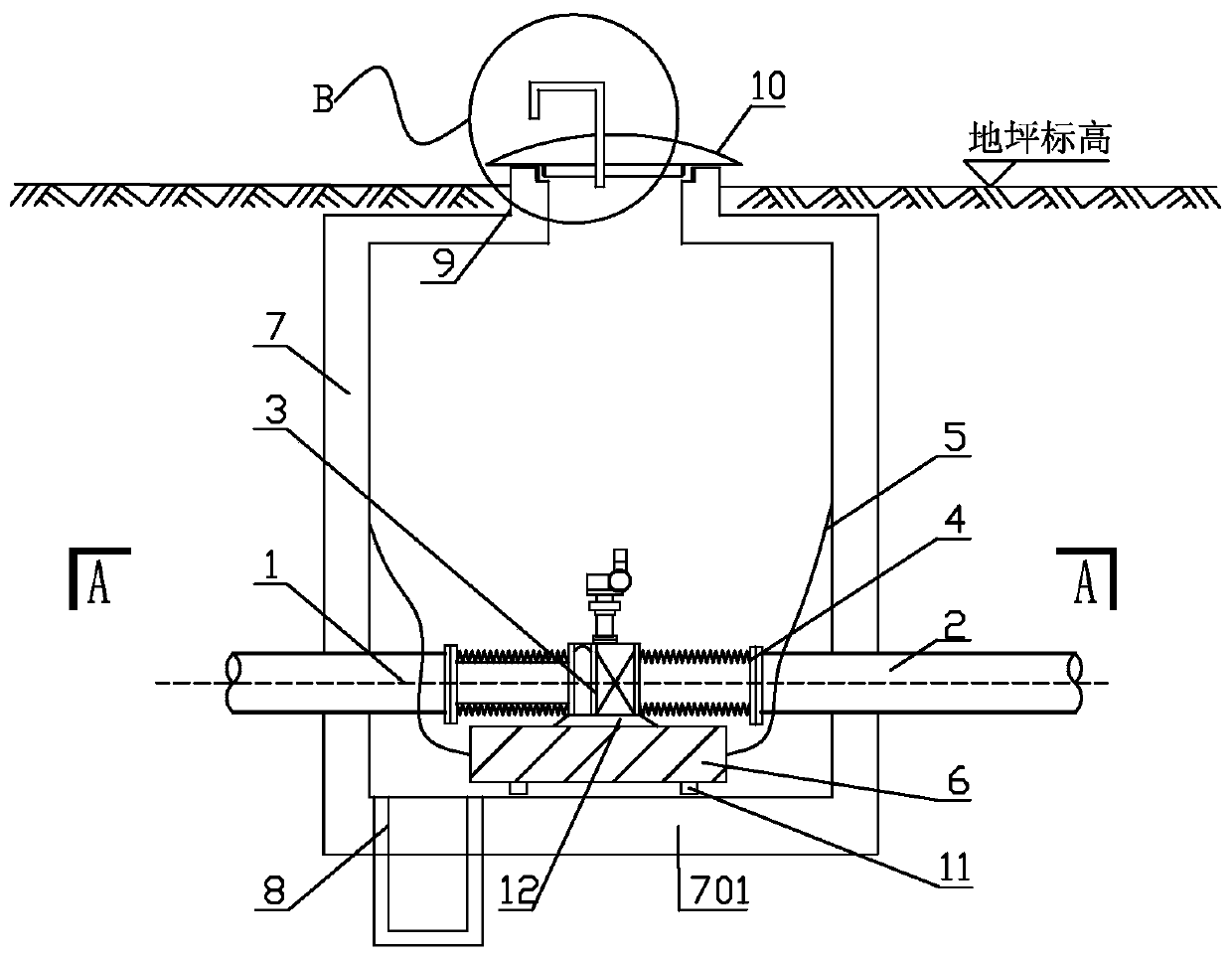

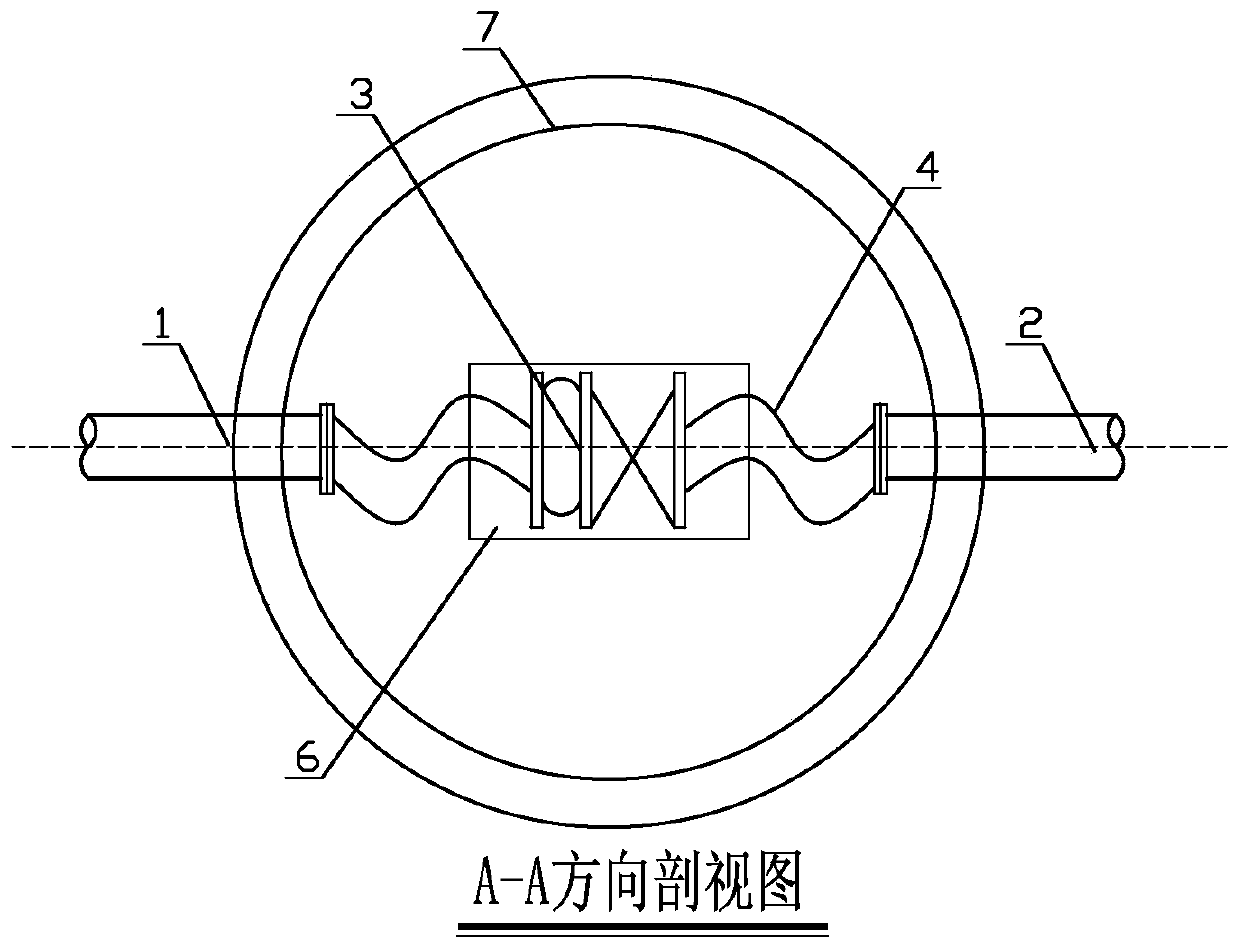

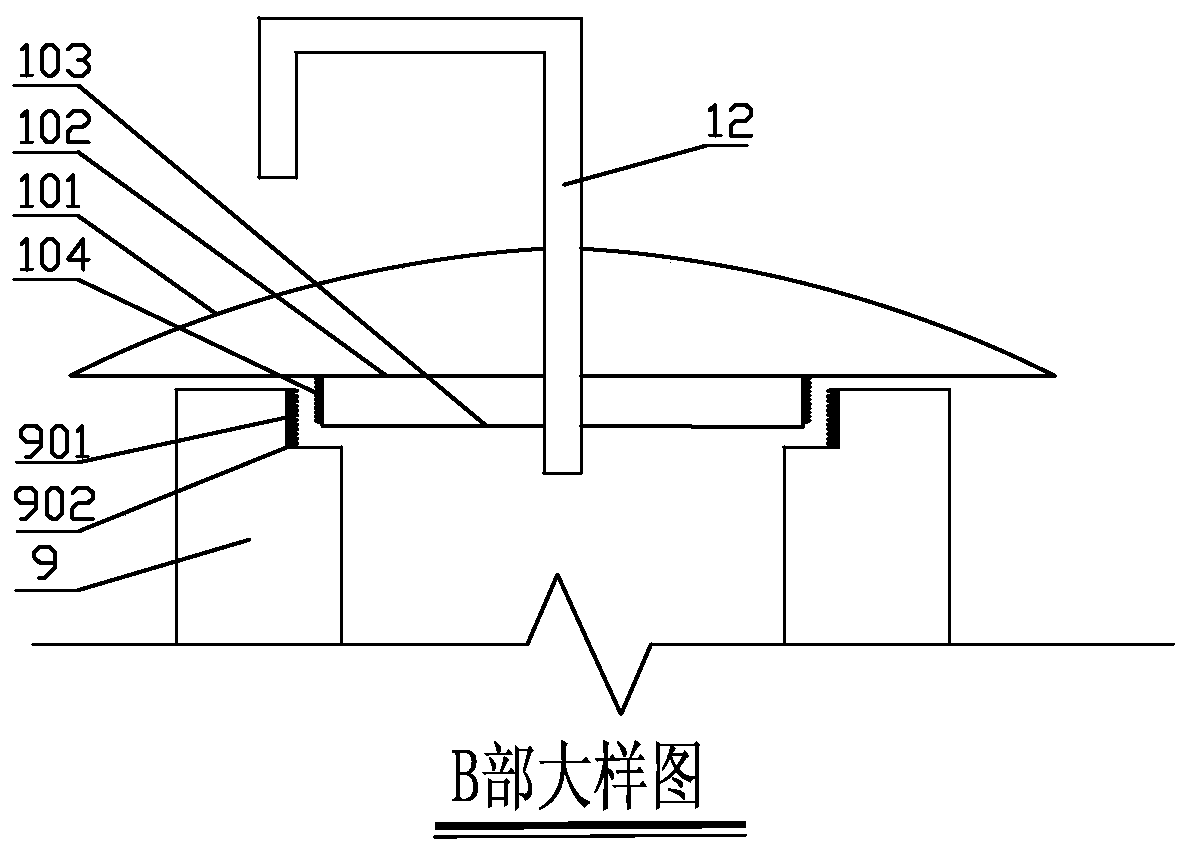

[0025] Such as Figure 1-Figure 3 As shown, it includes upstream pipe 1, downstream pipe 2, valve 3, flexible pipe 4, elastic traction rope 5, floating pad 6, well body 7, bottom plate 701, sump 8, inspection port 9, threaded well cover 10, upper cover 101 , lower cover 102 , swivel plate 103 , leg 11 and air duct 12 .

[0026] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

[0027] A lifting valve structure for sewage pipelines according to the present invention includes a well body 7, and round holes are symmetrically opened on the opposite side walls of the lower part of the well body 7, and an upstream pipe 1 and a downstream pipe 2 are respectively install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com