Method by utilizing micro-emulsion to prepare frozen puff

A microemulsion and emulsion technology, applied in the field of food processing, can solve the problems of increased cost, large business space, and low storage resistance of puffs, and achieve the effect of crispy taste, moderate skin thickness, and the same expansion degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

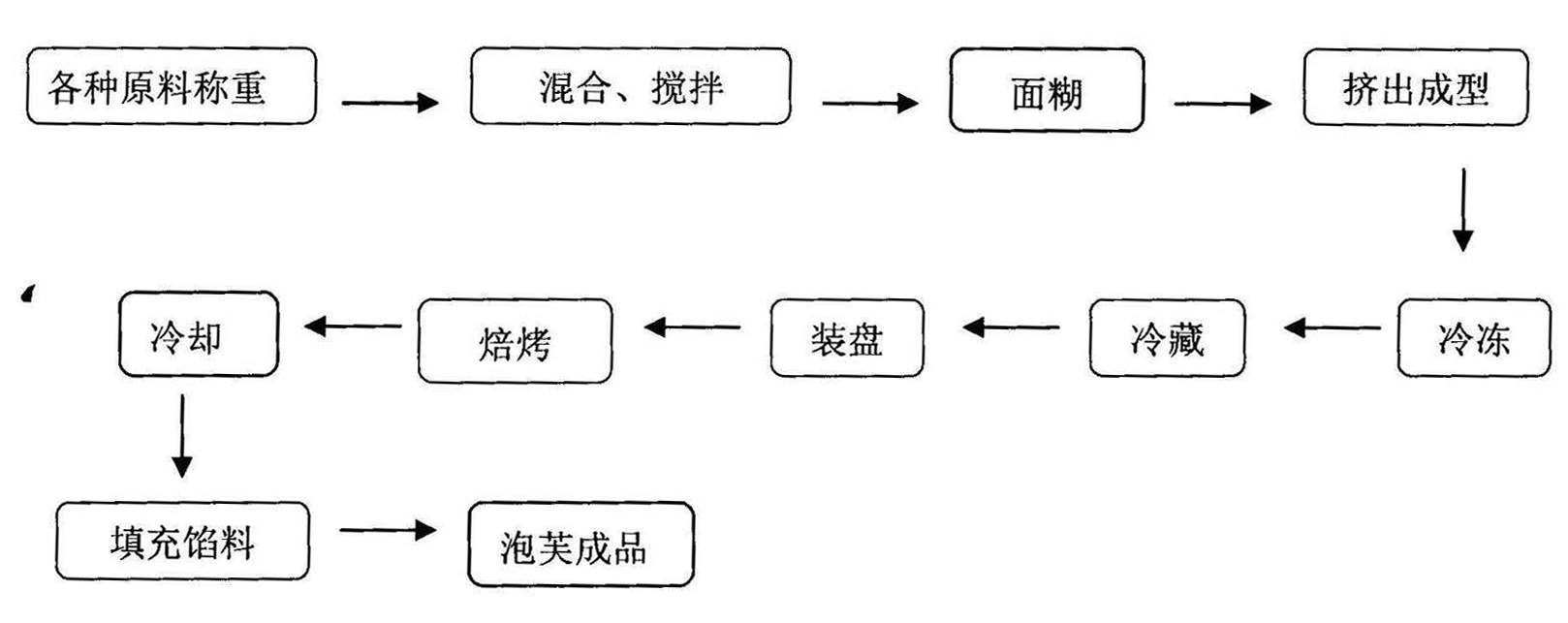

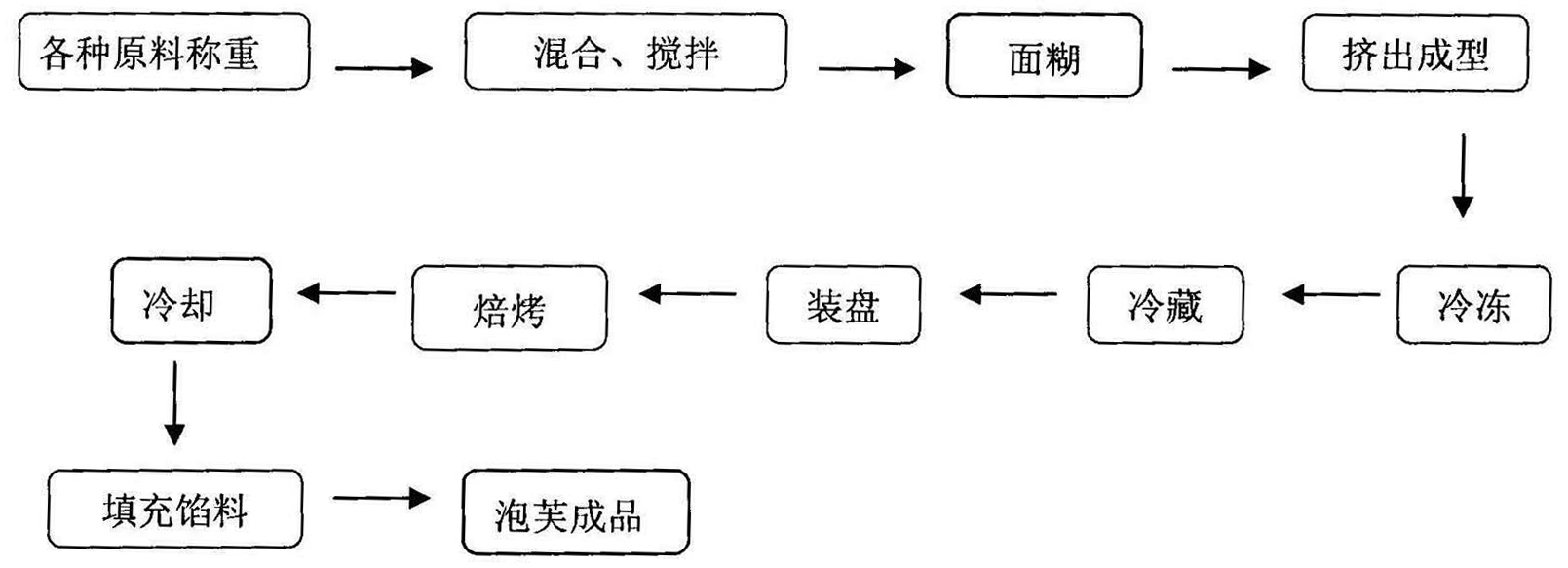

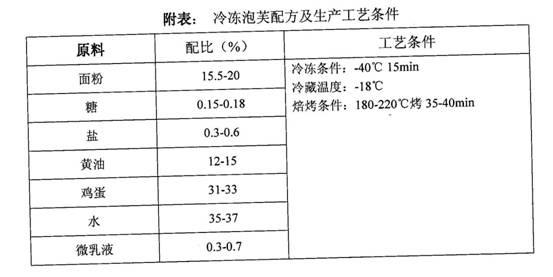

Method used

Image

Examples

Embodiment 1

[0013] a. Take potassium sorbate 0.004g / mL, Tween-80 0.001g / mL, sucrose fatty acid ester (SE-15) 0.003g / mL, sodium stearoyl lactylate (SSL) 0.0025g / mL and add water to prepare 10mL emulsion , then add 10mL of ethanol, 0.1g of salt, stir and add water to make a microemulsion;

[0014] b. Use the microemulsion as one of the liquid components of the batter formula, heat it together with water and butter, after the butter is completely melted, turn to low heat, wait until the temperature in the pot drops to 50-60°C, add flour, stir for 3-6 minutes , turn off the heat when a film appears on the bottom of the pot, and cool down; when the temperature in the pot drops to 40°C—that is, when there is still residual heat, put the beaten egg liquid into the pot several times and stir evenly. 2-5 minutes—that is, stir until the batter is dripped in an inverted triangle shape with the spatula, put the batter into a piping bag, squeeze it into a ball in a container with a shallow edge, and c...

Embodiment 2

[0018] a. Take potassium sorbate 0.004g / mL, Tween-80 0.001g / mL, sucrose fatty acid ester (SE-15) 0.003g / mL, sodium stearoyl lactylate (SSL) 0.0025g / mL and add water to prepare 10mL emulsion , then add 10mL of ethanol, 0.1g of salt, stir and add water to make a microemulsion;

[0019] B, the difference between this step and the step b of Example 1 is: the addition amount of the microemulsion is 0.4% of the flour weight.

[0020] The product prepared in this example was refrigerated at -18°C for two months and then baked. The finished product has a certain degree of expansion. The quality of puff products is no different.

[0021]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com