Processing method for bed die ferrules

A processing method and ferrule technology, applied in the field of mechanical processing, to achieve the effect of saving raw materials and reducing the amount of cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

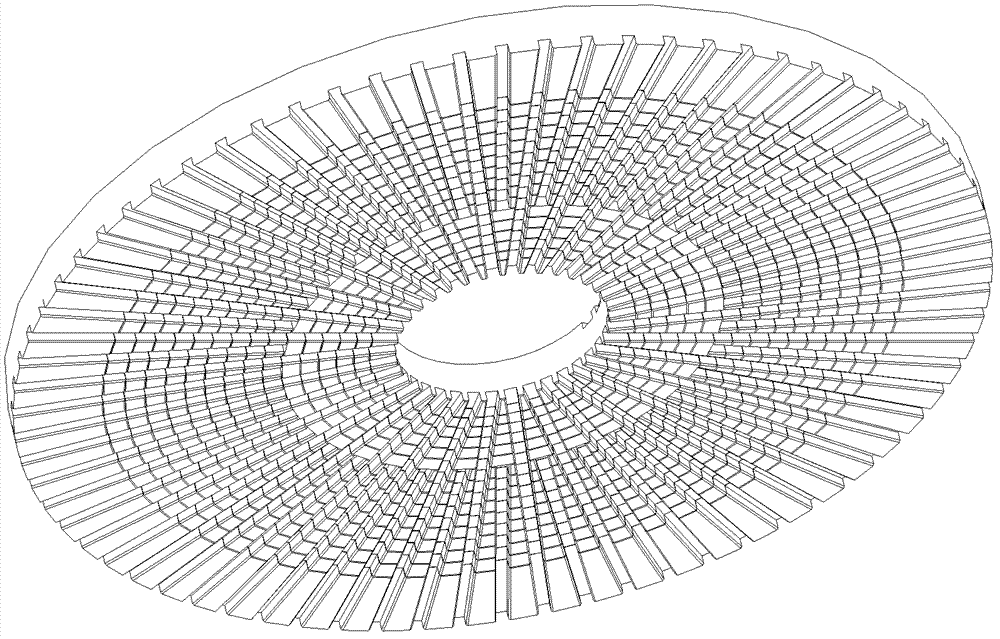

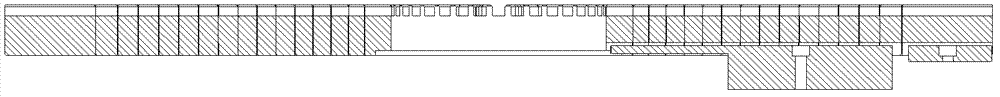

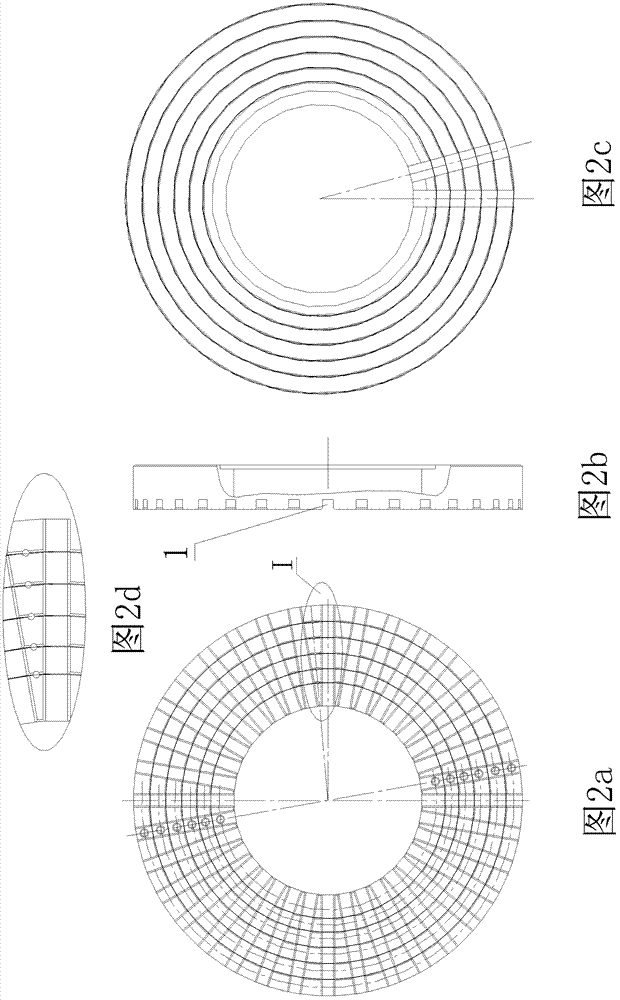

[0042] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0043] see Figure 1a-Figure 8 , the processing method of the bottom mold ring,

[0044] 1. Combine the single parts with 36 evenly distributed oil return tanks 1 into a whole and forge them into a disc shape; combine the parts with 72 evenly distributed oil return tanks 1 into a whole, forge them into a disc shape, and then The two disc-shaped parts are annealed.

[0045] 2. First of all, carry out overall rough turning for each disc-shaped part, leaving enough margin for inner and outer circles and end faces.

[0046] 3. Carry out quenching and tempering treatment on the disc-shaped blank, and make pre-organization preparation for subsequent quenching.

[0047] 4. For the overall semi-finishing disc-shaped blank, an appropriate margin is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com