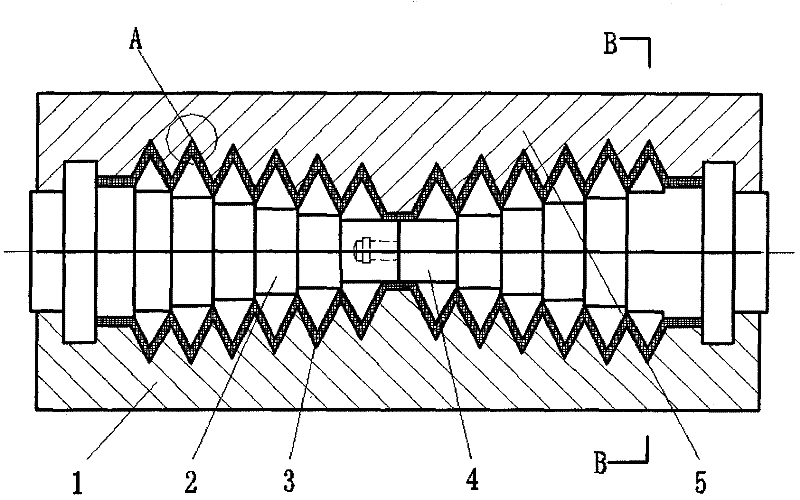

Forming die of special-shaped flexible bellows artificial muscle

An elastic bellows and molding die technology, which is applied to household appliances, tubular items, other household appliances, etc., can solve the problem of unspecified molding die structure, etc., and achieve the effect of simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

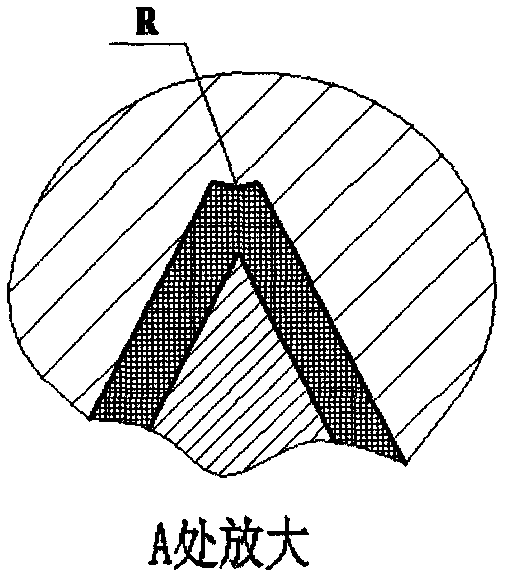

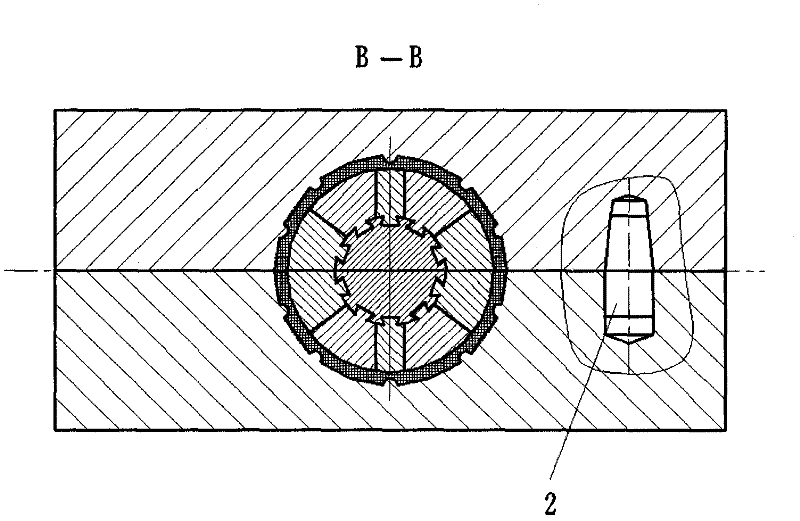

[0027] The invention is used to form the inner layer of the rubber corrugated pipe. The inner layer of the rubber corrugated pipe is not demoulded. The warp and weft yarns are directly braided on the mandrel, and then covered with a semi-vulcanized rubber material. Finally, the left core of the left core component 2 The rod 2a is extracted to the left, and the right core rod 4a of the right core member 4 is extracted to the right. After each petal is removed, the forming process is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com