Foamed composite board and manufacturing method thereof

A composite board and foaming agent technology, applied in chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve the problems of plastic products that are difficult to handle, high cost, waste materials, etc. Thick thickness, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

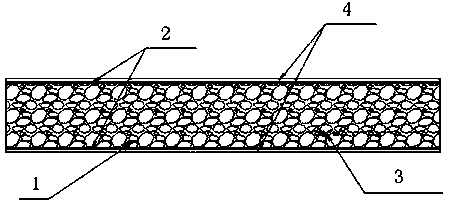

[0019] like figure 1 As shown, the present invention discloses a foamed composite board, comprising a foamed core layer 1, the foamed core layer 1 is composed of a composite material 2 and a foamed core board 3, and the foamed core layer 1 is foamed Porous structure, the upper part of the composite material 2 is provided with a color steel plate 4, and the porous structure of the foamed core layer 1 is respectively compounded with the color steel plate 4 and the composite material 2 by hot melting to form a composite board with a foamed cell structure. , the thickness range between the foamed core layer 1 and the color steel plate 4 is 4.5-12mm. According to the weight ratio, the foamed composite board is a composite of PE plastic particles with a foaming rate of 20%-40% and the color steel plate 4 product.

[0020] The invention also discloses a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com