Axially-sealed fluid pressure switcher with reciprocating sliders

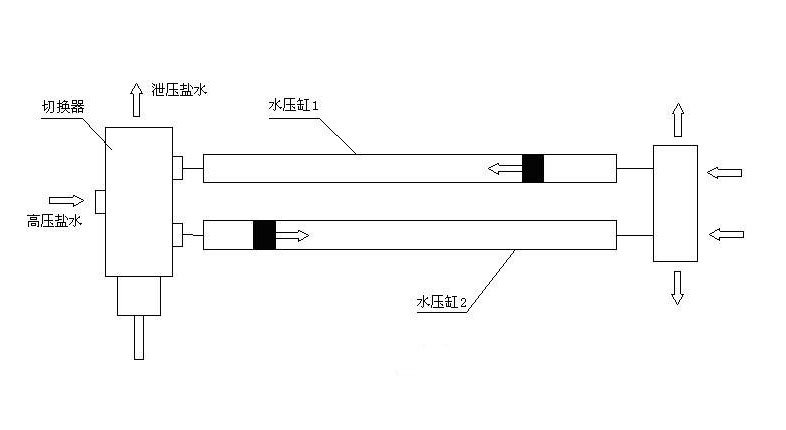

A technology of fluid pressure and axial sealing, which is applied in seawater treatment, osmosis/dialysis water/sewage treatment, etc. It can solve problems such as difficulty in guaranteeing piston sealing effect, high processing precision requirements, complex processing technology, etc., so as to achieve easy processing and easy Leakage, control precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

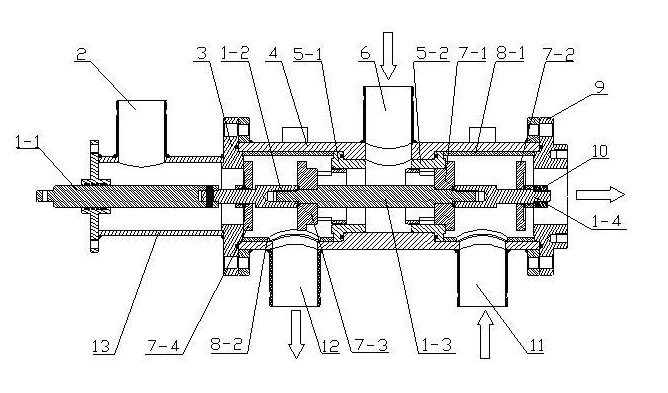

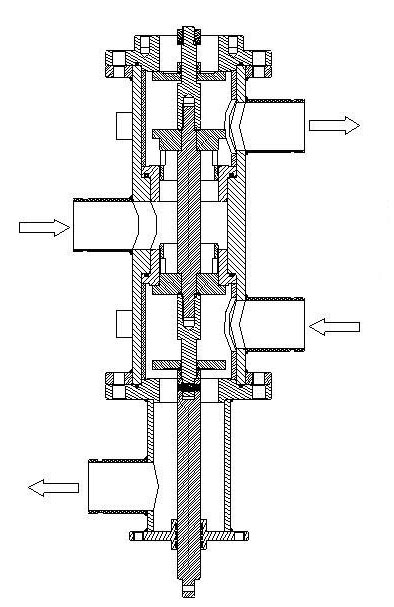

[0020] The present invention will be further described below in conjunction with accompanying drawing. figure 2 It is a structural schematic diagram of the fluid pressure switcher of the present invention. In the figure, the high-pressure section housing 4 has an outer diameter of Φ190 mm, a wall thickness of 15 mm, and a length of 530 mm; the housing is connected to a fluid inlet pipe 6 with an inner diameter of Φ80 mm, and the hydraulic cylinder connecting pipe The inner diameters of Ⅰ12 and hydraulic cylinder connecting pipe Ⅱ11 are both Φ80mm; one end of the shell is connected to the pressure relief port stop ring 9 through the flange and bolts on it. The pressure relief port stop ring is flange-shaped, with a hole in the middle, and the inner diameter is Φ100mm; the other end of the high-pressure section shell is connected to the connecting retaining ring 3 through a flange, and the middle aperture of the connecting retaining ring is Φ100mm; the connecting retaining ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com