Method for preparing dihydrodicyclopentadiene through continuous reaction

A technology of hydroxydihydrodicyclopentadiene and dicyclopentadiene, which is applied in the preparation of hydroxyl addition, organic chemistry, etc., can solve the problems of serious carbonization of raw materials, non-continuous production, long reaction time, etc., and achieve high production efficiency, Easy to operate and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

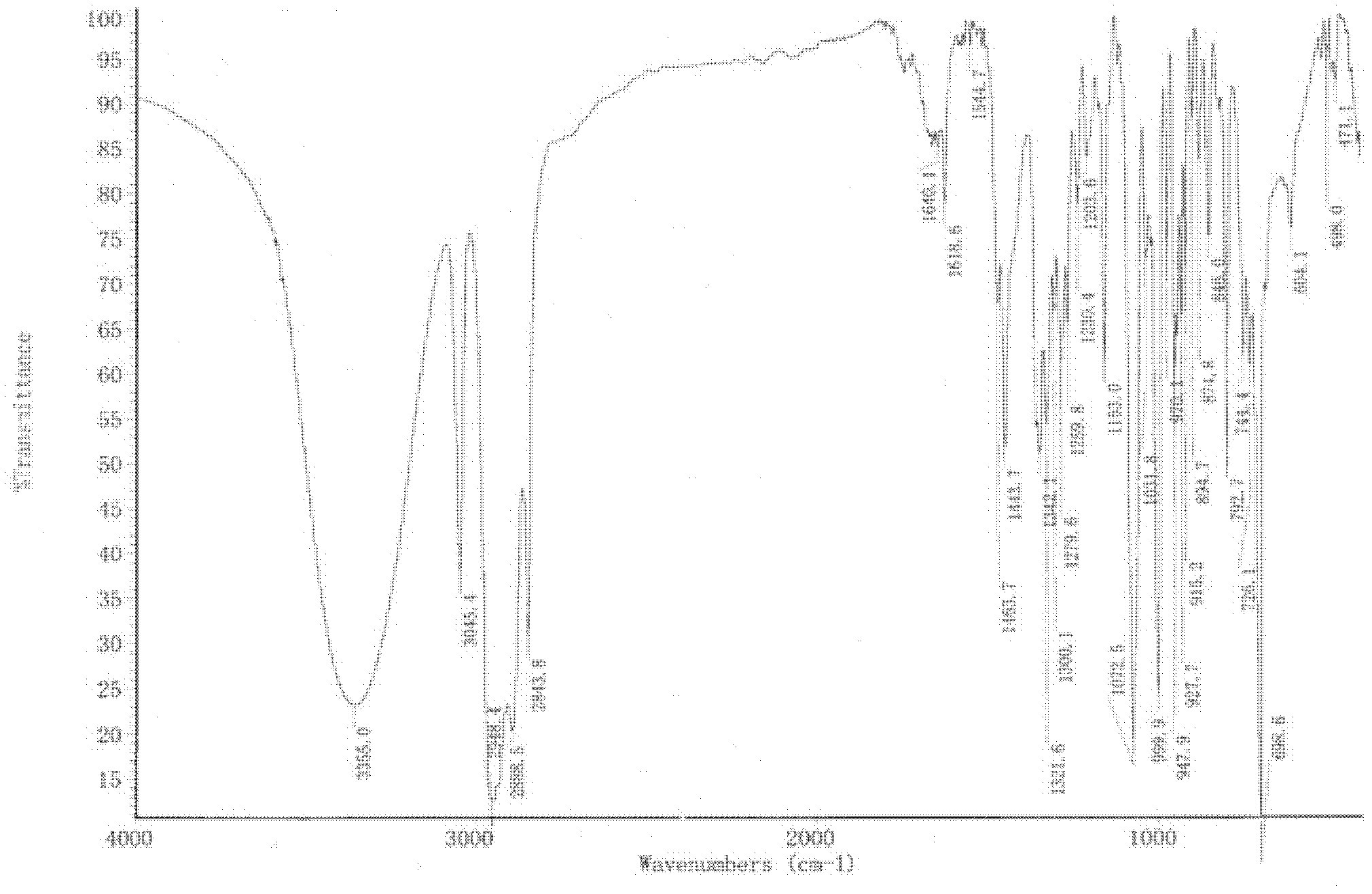

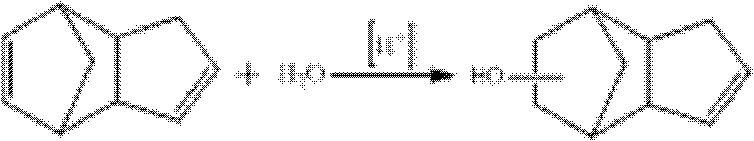

Image

Examples

Embodiment 1

[0019] Embodiment 1,2,6,7 is to use sulfuric acid, phosphoric acid, p-toluenesulfonic acid, hydrochloric acid as catalyzer respectively in continuous stirred tank reactor, take dicyclopentadiene as raw material to carry out hydration reaction; Embodiment 3,4, 8 is to carry out hydration reaction with p-toluenesulfonic acid, phosphotungstic heteropolyacid and acidic ionic liquid as catalyst respectively in tubular reactor; embodiment 5 is to carry out dicyclopentadiene with sulfuric acid as catalyst in microstructure reactor Hydration reaction.

[0020] Example 1

[0021] Add polycyclopentadiene solution and 5% sulfuric acid solution according to the molar equivalent ratio of 1:5, while adding the temperature at 60°C, the volume is 20m 3 In the continuous stirred tank reactor (belonging to the technical scheme of the present invention), the stirring speed is 200r / min, and the average residence time is 300min. After washing, centrifugal separation and drying, hydroxydihydrodic...

Embodiment 2

[0023] The liquid polycyclopentadiene solution and 85% phosphoric acid solution are in a molar equivalent ratio of 2:1, while the temperature is controlled at 120°C, and the volume is 20m 3 In two identical series continuous stirred tank reactors, the stirring speed is 300r / min, the average residence time is 10min, the outlet pipe is immersed in a flowing room temperature water bath to cool down to terminate the reaction, the reaction product is collected, and the product solution is washed, After centrifugal separation and drying, hydroxydihydrodicyclopentadiene was obtained with a yield of 69%.

Embodiment 3

[0025] The liquid polycyclopentadiene solution and 20% p-toluenesulfonic acid solution are in a molar equivalent ratio of 1:4, and at the same time, the liquid chromatographic pump is pumped into a tube with a temperature of 40 °C, a diameter of 100 mm, and a length of 5 m. In the reactor, the residence time of the material is 5min. The outlet pipe is soaked in a flowing room temperature water bath to cool down to terminate the reaction, and the reaction product is collected. The product solution is washed, centrifuged, and dried to obtain hydroxydihydrodicyclopentadiene. The rate is 59%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com