High-efficiency conveying device and method for underground materials of mines

A technology for transportation devices and materials, which is applied in underground transportation, transportation and packaging, earthwork drilling and mining, etc. It can solve problems such as environmental pollution, damage to human health, and hazards in underground operations, and achieve less maintenance tasks, save electricity, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and examples.

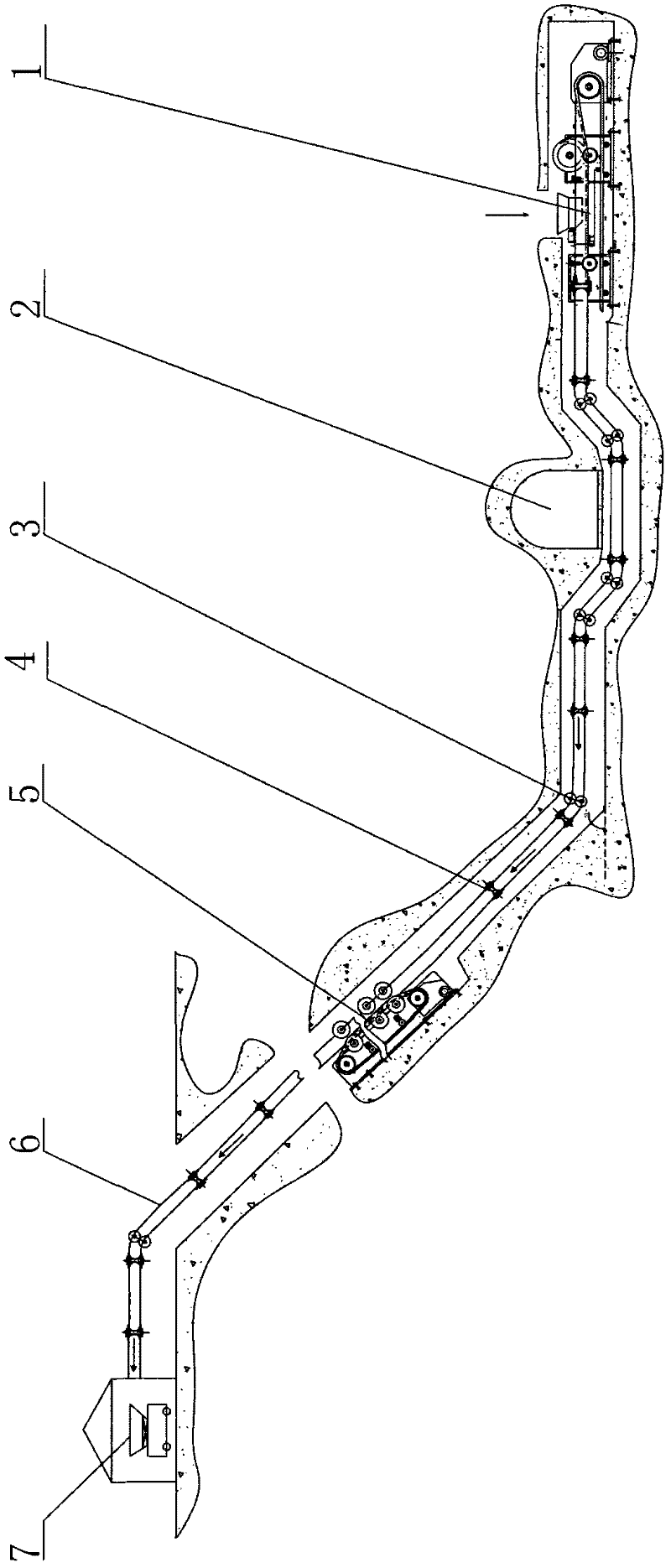

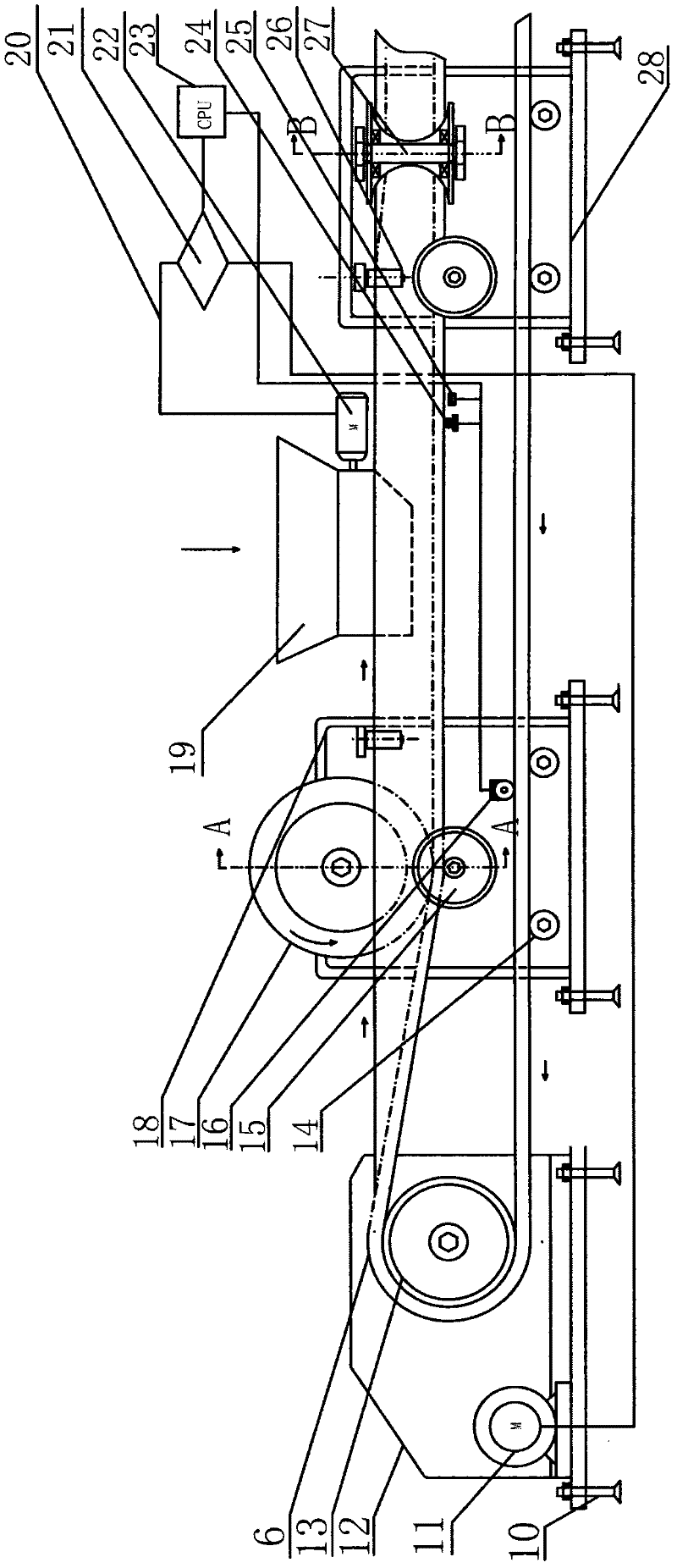

[0034] Such as figure 1 As shown, the mine underground material transportation device of the present invention includes a charging and driving device 1 connected in series through a conveyor belt 6, several groups of O-shaped roller devices 4, guide roller groups 3 and a conveyor belt power compensation device 5. The discharge end of the conveyor belt 6 transports the material to the ground handling facility 7 .

[0035] In order to avoid encountering unrelated shafts 2 that may pass through various types of underground equipment, the mine underground material transportation device passes under unrelated shafts 2 in a buried manner, and can also pass above unrelated shafts 2 .

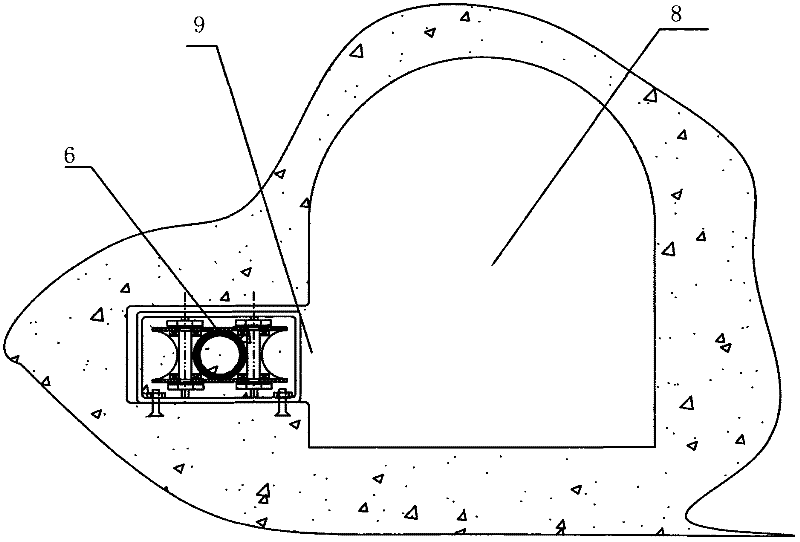

[0036] In order to facilitate the installation, repair and maintenance of the mine underground material transportation device of the present invention, the mine underground materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com