Torque sensor

A technology of torque sensor and induction port, which is applied in the direction of torque measurement, instruments, measuring devices, etc., can solve the problem of low measurement accuracy of torque sensor, and achieve the effects of high reliability, improved measurement accuracy and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

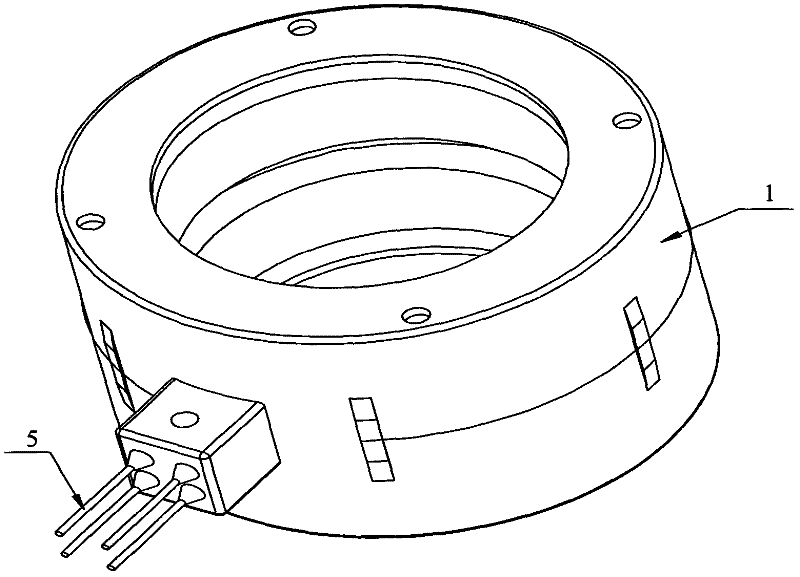

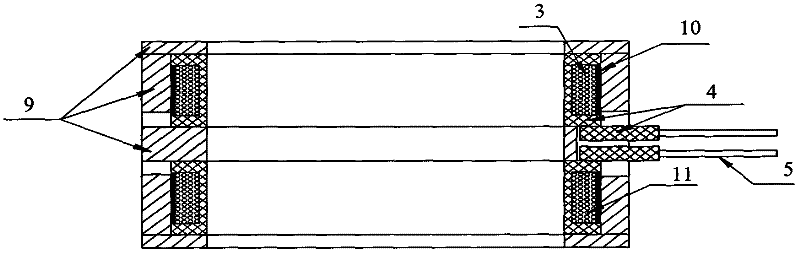

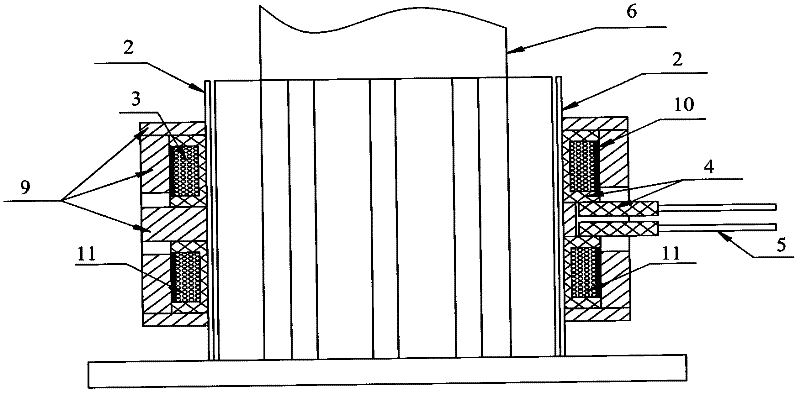

[0018] Such as Figure 1-Figure 4 As shown, a torque sensor is disclosed, including a housing 1, two sets of induction coils and a magnetic isolation sleeve 2, the housing 1 is in the shape of a hollow cylinder, and the two sets of induction coils include a first induction coil 3 and a second induction coil 11 , the first induction coil 3 and the second induction coil 11 are wrapped in the shell 1 parallel to each other, and the coils inside the first induction coil 3 and the second induction coil 11 have current access, so a certain inductance can be generated. The first induction coil 3 and the second induction coil 11 are insulated from each other. The innermost layer of the shell 1 is equipped with a magnetic isolation sleeve 2. The magnetic isolation sleeve 2 is generally made of aluminum. 6. The positions corresponding to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com