Method, system and refiner for refining of wood chips or pulp fibers

A refiner and pulping fiber technology, applied in pulp beating/refining methods, fiber raw materials, fiber raw material processing, etc., can solve problems such as obstruction and blockage of the outlet or outlet of the refiner, and achieve avoidance of evaporation, cost savings, easy to dissolve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

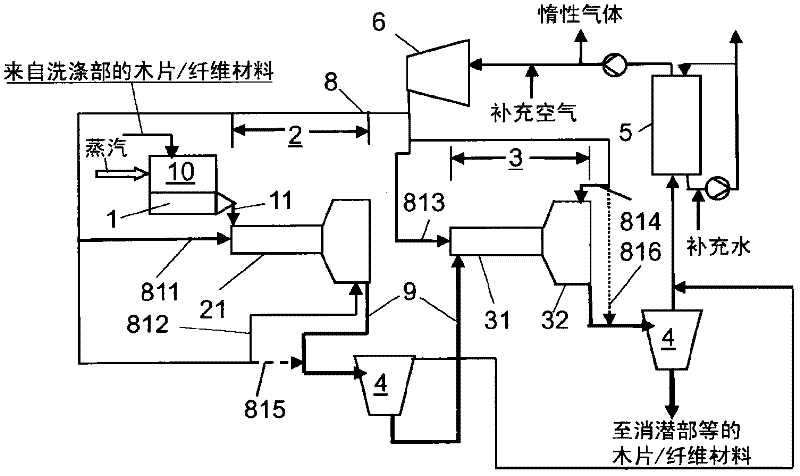

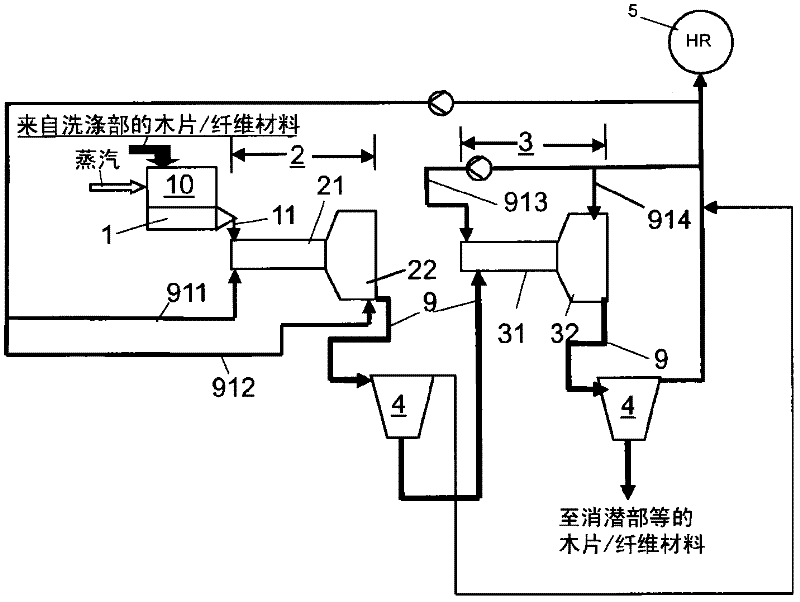

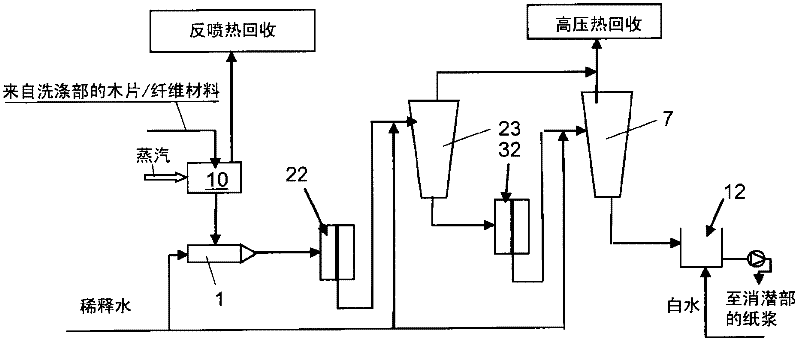

[0033] For a better understanding of the basic principles of the invention, refer to figure 1 , this figure shows A TMP refining line according to the prior art of a paper mill. The TMP line comprises a preheating unit 10, a first refiner 22, a steam cyclone 23, a second refiner 32, a separator device (such as a stripping cyclone 7), an outflow duct, and a receiving vessel 12, The receiving vessel 12 is used to receive separated wood chip / pulp material from the stripping cyclone 7 . For the sake of clarity, the feeder unit preceding the refining stage is defined below as a Peri-type feeder, "Peri-type feeder" being the trade name for a feeder unit preceding the refining stage.

[0034] according to figure 1 The production of the refiner line shown can be regulated by controlling the rotational speed of the plug screw 1 which will have been preheated by the water unit 10 at a temperature of the mixture of 70°C The heated chips are fed to the first refining stage 2. By adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com