Compound-function binocular vision sensor suitable for movable independent welding robot

A welding robot and composite function technology, applied in welding equipment, manipulators, arc welding equipment, etc., can solve the problems of inability to fully satisfy diversification, less freedom, poor stability, etc., and meet the requirements of visual information collection and movement space restrictions The effect of less, easy replacement and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

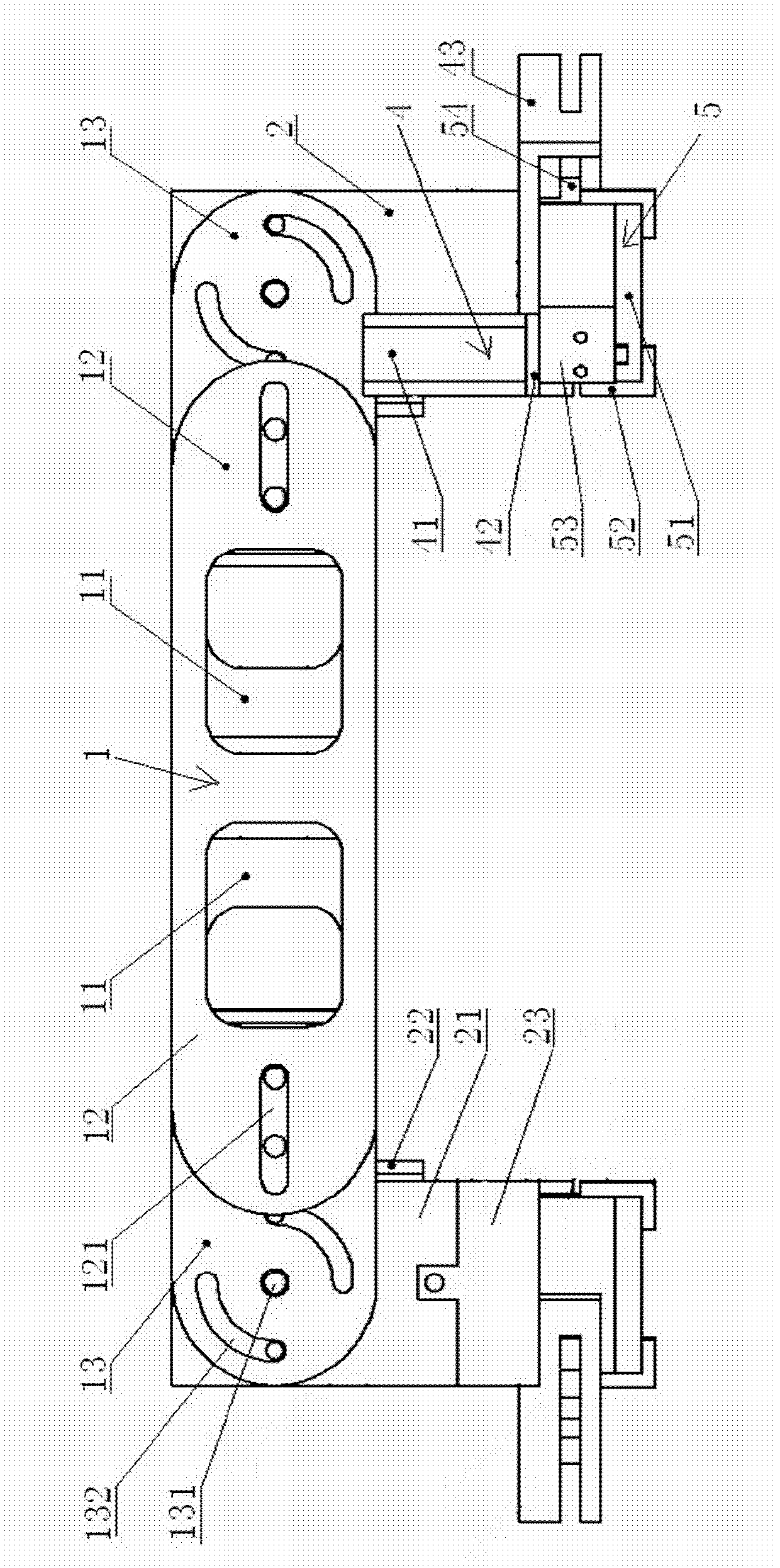

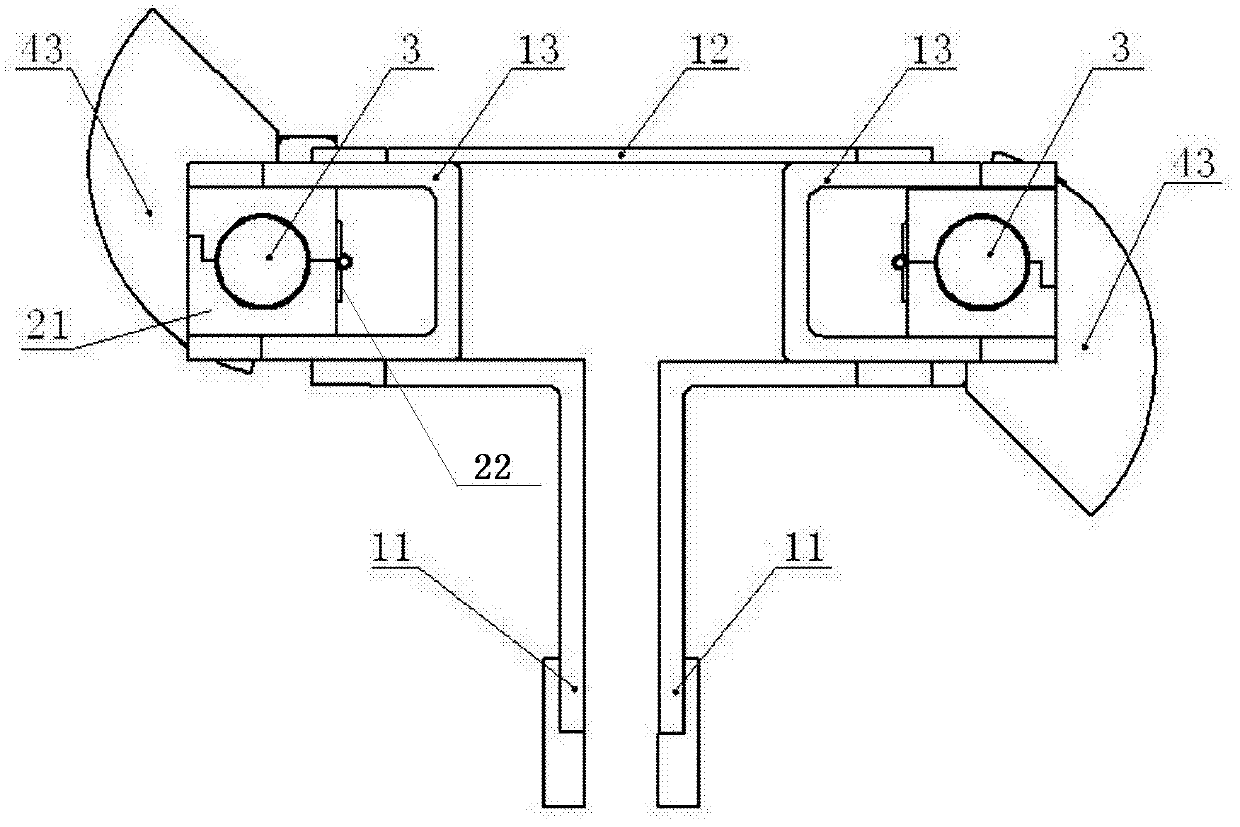

[0026] Such as figure 1 with figure 2 As shown, this embodiment includes a fixture 1 , two camera brackets 2 , two cameras 3 (for CCD cameras), two motor rotation mechanisms 4 and two light reduction filter systems 5 . in:

[0027] Fixture 1 is fixed on the end joint of the welding robot;

[0028] Two camera supports 2 are all installed on the fixture 1, and each camera support 2 is equipped with a described camera 3 and a described motor rotation mechanism 4, and these two cameras 3 are fixed on the mobile robot with the welding gun shaft (the welding gun is also fixed on the mobile robot on the end joint) is arranged symmetrically to the center;

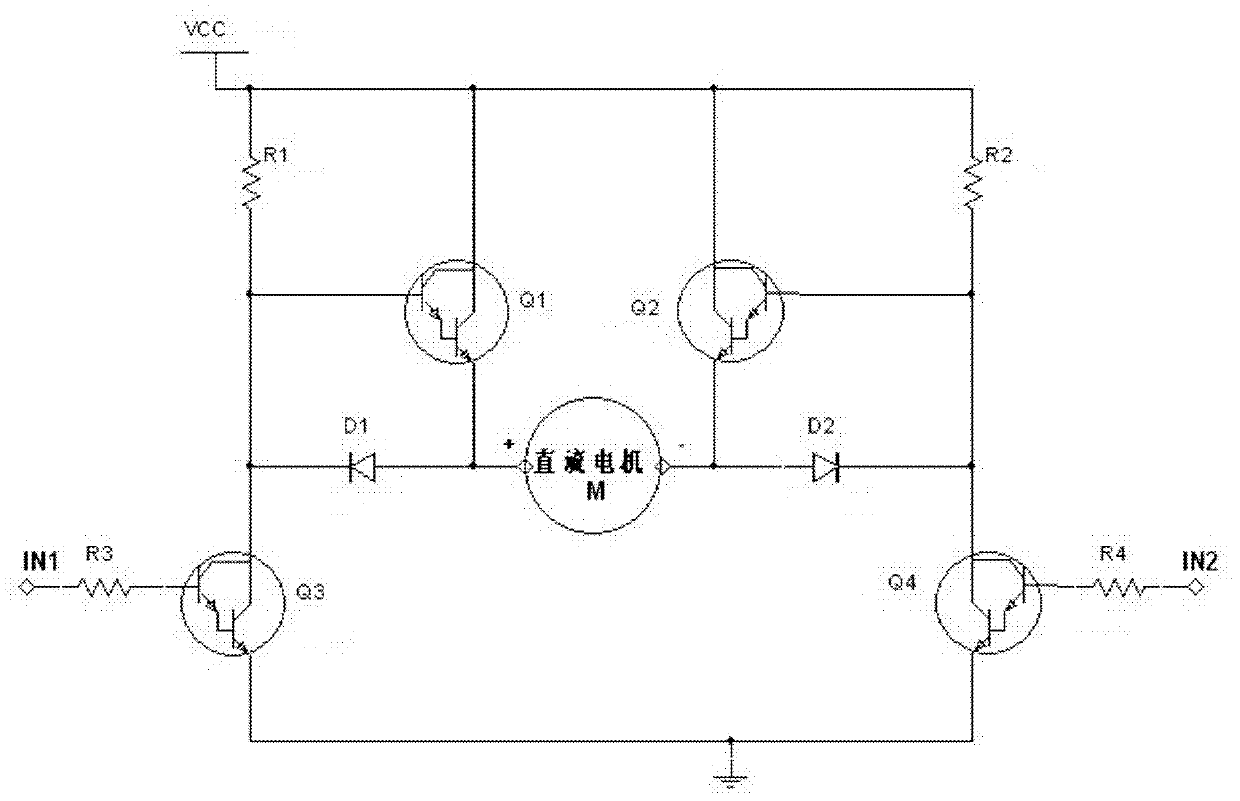

[0029] The light reduction filter system 5 is connected with the motor rotation mechanism 4 and driven by the motor rotation mechanism 4 to rotate, so that the light reduction filter system 5 is transferred into / out of the field of view of the camera 3, specifically: 1) during the welding process, the The optical filter system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com