Reconfigurable tool for pipeline integral welding

An integral, welding technology, applied in the field of fixtures, can solve the problems of time-consuming, complicated operation and adjustment, affecting the production efficiency of pipeline product assembly and welding, and achieve the effect of avoiding interference and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and example the present invention will be further described:

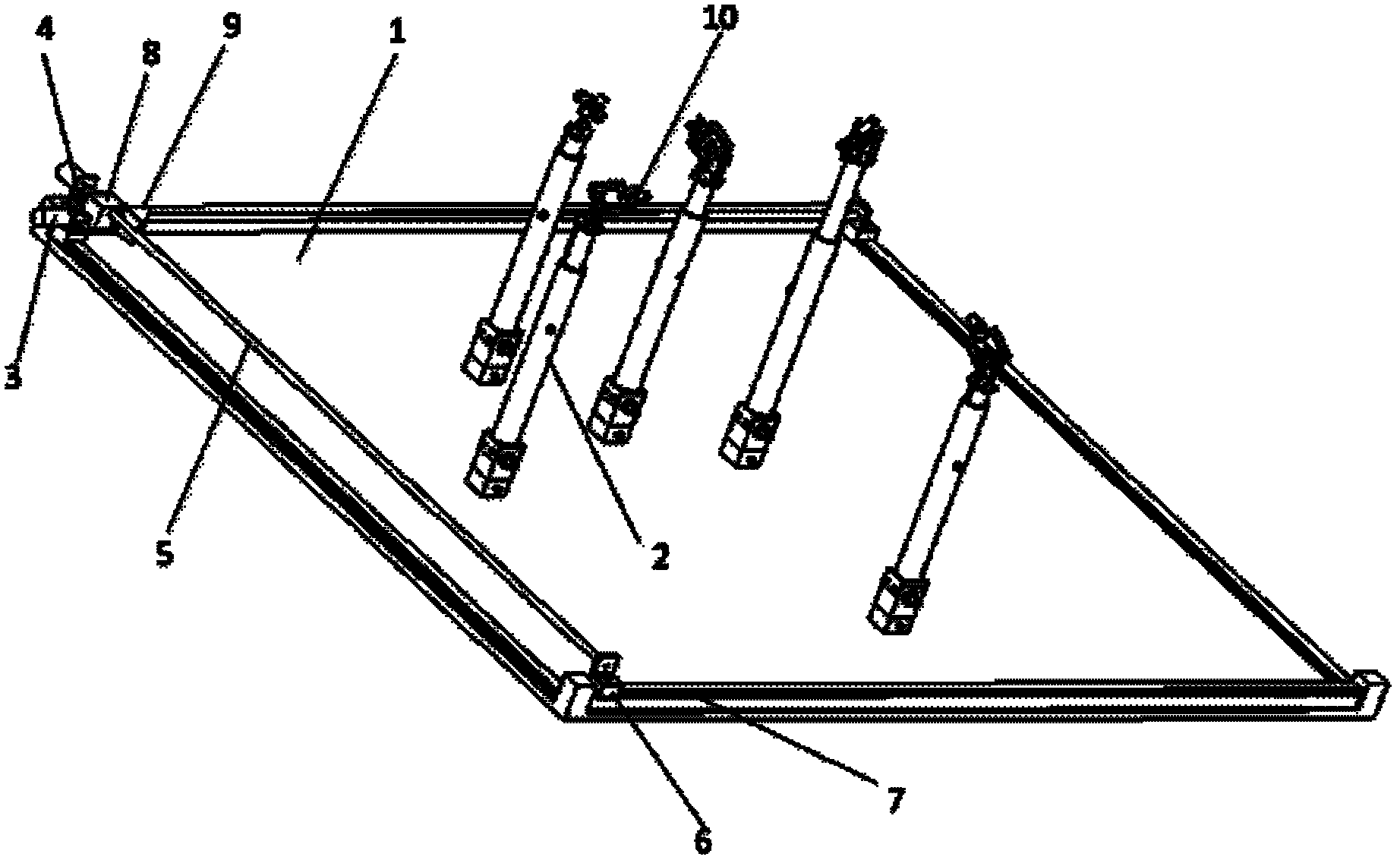

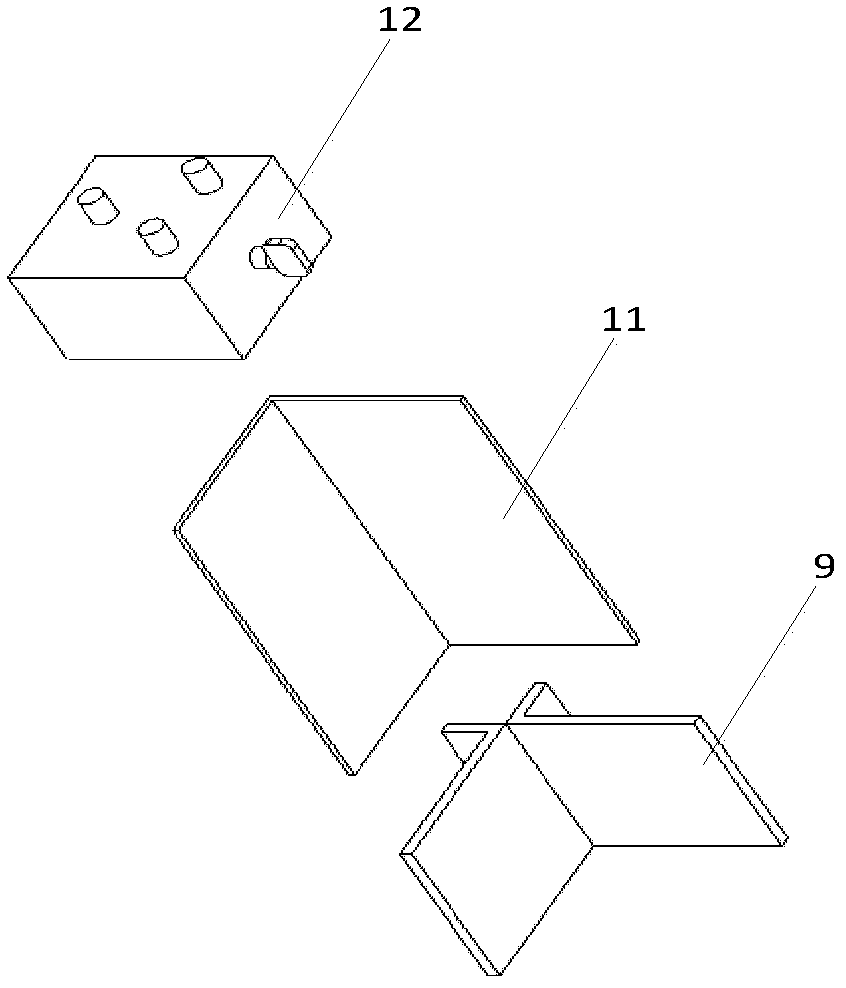

[0018] Such as figure 1 with figure 2 Shown, the present invention mainly is made of working platform 1, locator 2, motor 3, shaft coupling 4, leading screw 5, slide block 6, slide rail 7, positioning block 8, positioning piece I9 and positioning piece II11. Wherein, the motor 3 drives the lead screw 5 to rotate, the slider 6 slides on the slide rail 7, and then drives the positioning block 8 to move, and completes the positioning of the positioning piece 19 installed on the positioning block 8 in the X and Y directions in the plane of the working platform 1. For precise positioning, the positioning piece I9 cooperates with the positioning piece II11, and then the locator base 12 cooperates with the positioning piece II11 to complete the positioning of the locator base 12 on the working platform 1.

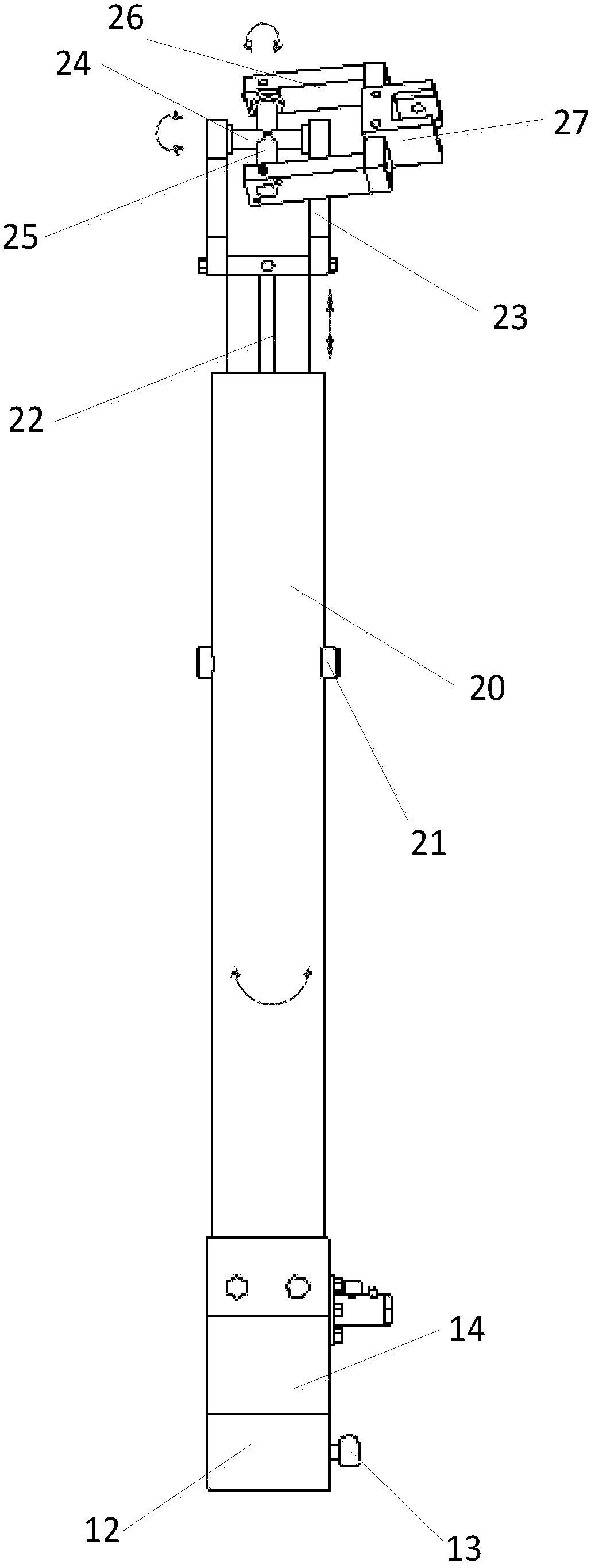

[0019] Such as image 3 with Figure 4 As shown, the loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com