Front body framework structure of automobile

A skeleton structure, automobile body technology, applied in the direction of load-bearing body structure, superstructure, vehicle parts, etc., can solve the problems of unreasonable energy dispersion, damage to the body frame, large deformation of the floor and middle passage, and reduce vehicle maintenance costs. , Reasonable energy dispersion, reducing the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

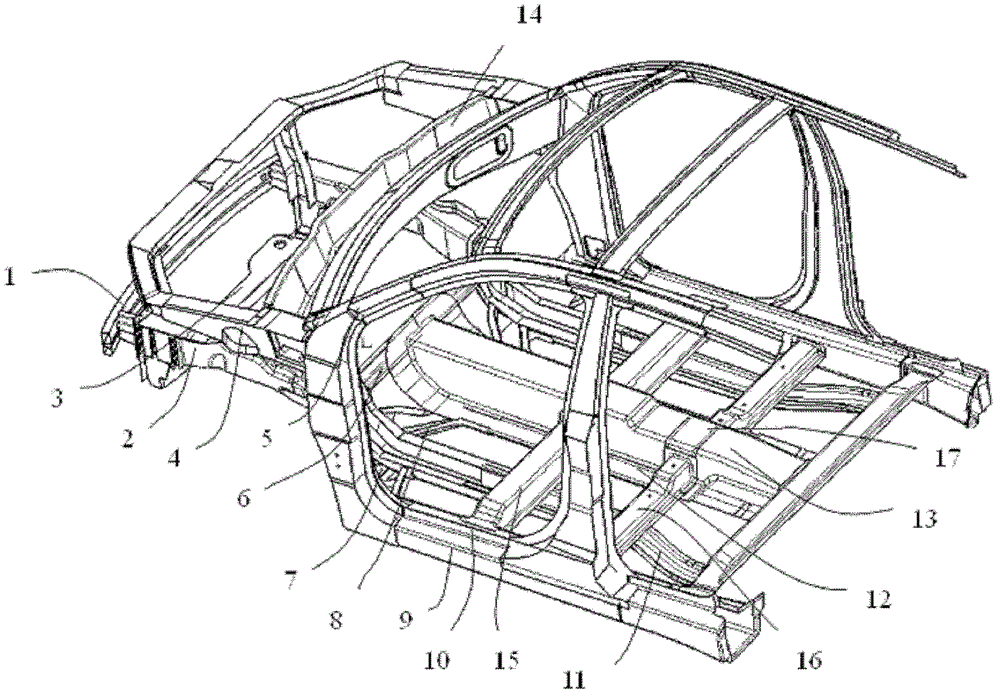

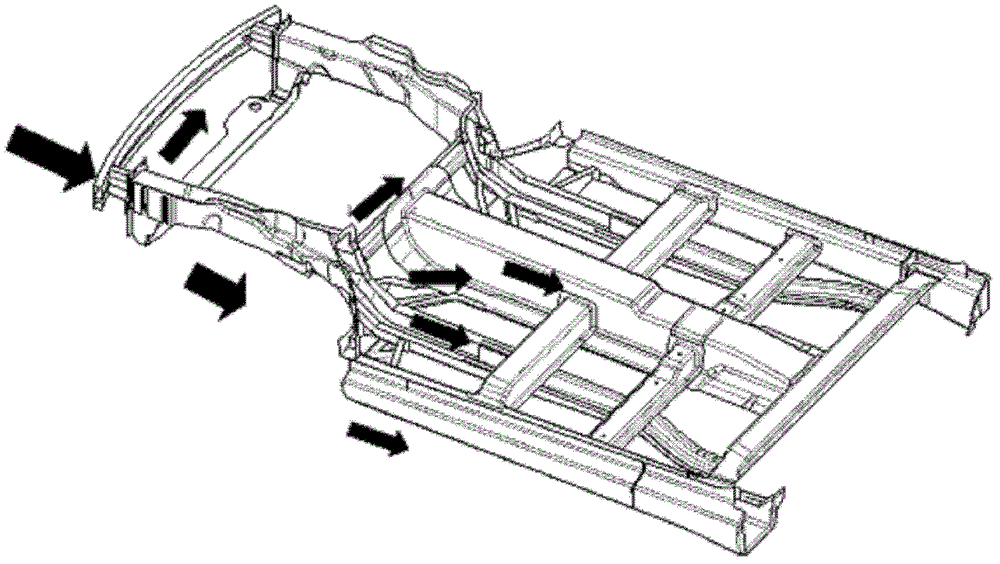

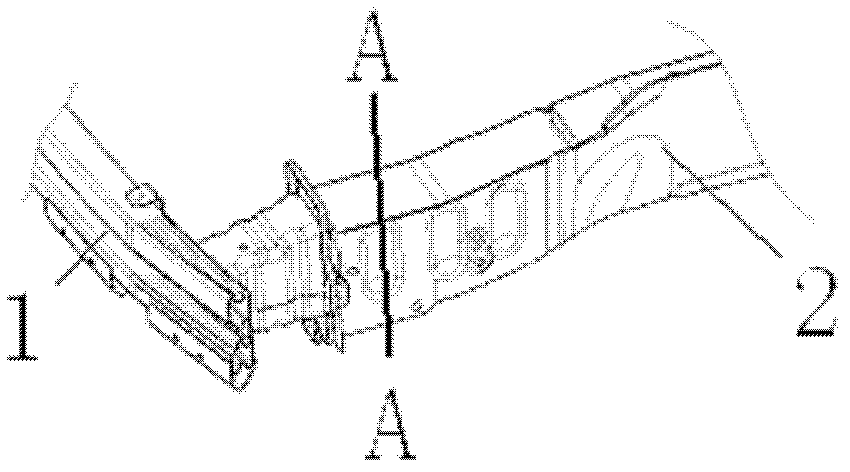

[0021] Such as figure 1 As shown, the present invention is a skeleton structure of the front part of the automobile body. A body skeleton structure is constructed through multi-channel connected body beams, so as to reduce the damage value of the vehicle body to the occupant and the maintenance cost of the vehicle itself during the collision process. The body skeleton mainly It is composed of A-pillar 5 of the vehicle body, front crossbeam 1, front cabin frame assembly and front floor frame assembly. The front floor frame assembly includes a front floor longitudinal beam 11, a lower door sill, and a plurality of longitudinal beams and crossbeams connected to the front floor longeron 11 and the lower door sill to disperse and transmit collision energy. The lower sill includes a side wall lower sill 9 on the outer side of the vehicle body and an inner sill 10 on the inner side. The front cabin frame assembly includes the front cabin longitudinal beam 2, the water tank lower bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com