Solid descaling acid rod for oil well

A solid acid and solid technology, applied in the field of descaling agents for oil wells, can solve the problems of strong acid, strong corrosion, inconvenient production and use, local corrosion, pipeline scaling and blockage, etc., and achieve a high success rate of removing obstacles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Preparation of solid descaling acid stick for oil well:

[0017] Solid descaling acid stick for oil wells, its composition includes main acid, cement, weighting agent, anti-water absorption agent; said main acid includes:

[0018] Sulfamic acid, nitric acid powder, ethylenediaminetetraacetic acid (EDTA), penetrant, corrosion inhibitor, cleaning agent.

[0019] The cement adopts sodium carboxymethyl cellulose (CMC), and the weighting agent adopts zinc bromide ZnBr 2 , The anti-absorbing agent is cationic polyacrylamide, the penetrating agent is Pingpingjia with a polymerization degree of 30, the corrosion inhibitor is thiourea, and the cleaning agent is sodium dodecylbenzenesulfonate.

[0020] The composition of the solid descaling acid bar for oil wells is as follows according to weight percentage: 88.4% for solid acid, 1.8% for thiourea, 1.8% for sodium dodecylbenzenesulfonate, and 3.6% for Pingpingjia with a degree of polymerization of 30 %, sodium carboxymethylcell...

Embodiment 2

[0026] Embodiment 2: the influence of reaction temperature on descaling efficiency

[0027] The solid descaling acid stick prepared in Example 1 was selected to investigate the descaling efficiency of the solid descaling acid stick on calcium carbonate scale and calcium sulfate scale at different temperatures, and the reaction time was 24 hours. The test result of the solid descaling acid stick of the present embodiment is as follows table 1:

[0028] Table 1 Dissolved amount of solid descaling acid stick at different temperatures

[0029] Reaction temperature, °C

[0030] It can be seen from the table that with the increase of reaction temperature, the descaling efficiency increases, and the higher the temperature, the higher the descaling efficiency of calcium carbonate scale. For calcium sulfate scale, due to its poor solubility, its scale dissolving capacity is less than that of calcium carbonate scale. , The descaling efficiency is also lower than that of calci...

Embodiment 3

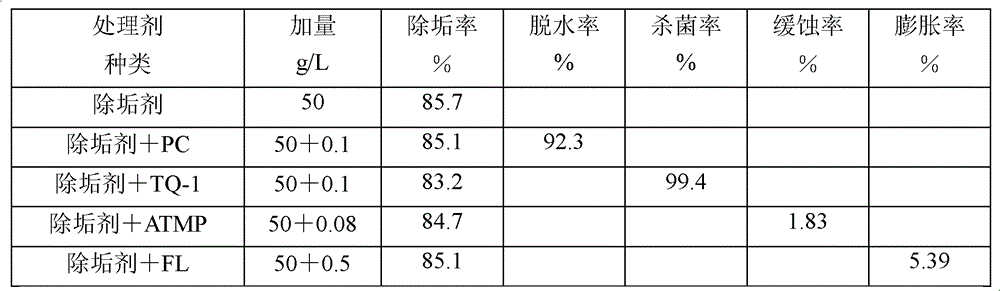

[0037] Example 3: Compatibility of solid descaling acid sticks with other treatment agents

[0038] In the treatment of oilfield sewage, in addition to descaling agents, it also contains a lot of oilfield additives, such as demulsifiers, corrosion inhibitors, bactericides, etc. Compatibility test was carried out between stabilizer FL and flocculant PC and the solid descaling acid stick prepared in Example 1. The scale removal rate is the scale removal rate of carbonate, the sterilization rate is tested according to the method specified in the oil and gas industry standard SY / T5890-93, and the corrosion inhibition rate is tested according to the method specified in the oil and gas industry standard SY / T5273-91. The test results of the solid descaling acid stick of this embodiment are shown in Table 3.

[0039] Table 3 Compatibility of solid descaling acid stick and other treatment agents

[0040]

[0041] It can be seen from the table that after adding other treatment agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com