Silicone oil shock absorber

A technology of shock absorber and silicone oil, which is applied in the direction of shock absorber, spring/shock absorber, shock absorber, etc., can solve the problems of limited damping effect of spring shock absorber, long service life of spring, easy deformation and failure, etc. To achieve the effect of compact structure, convenient installation, and reduced production and management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific drawings and embodiments.

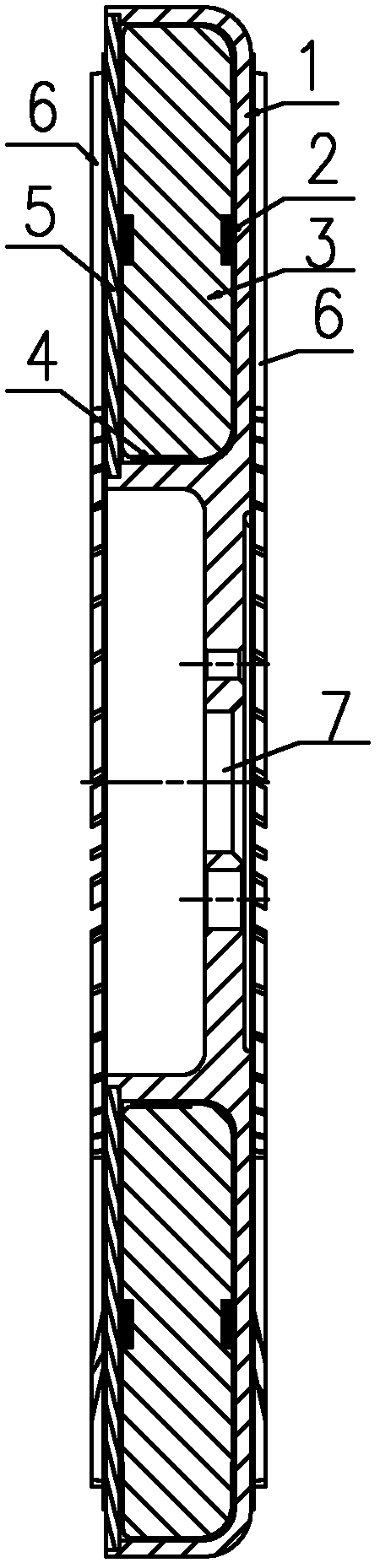

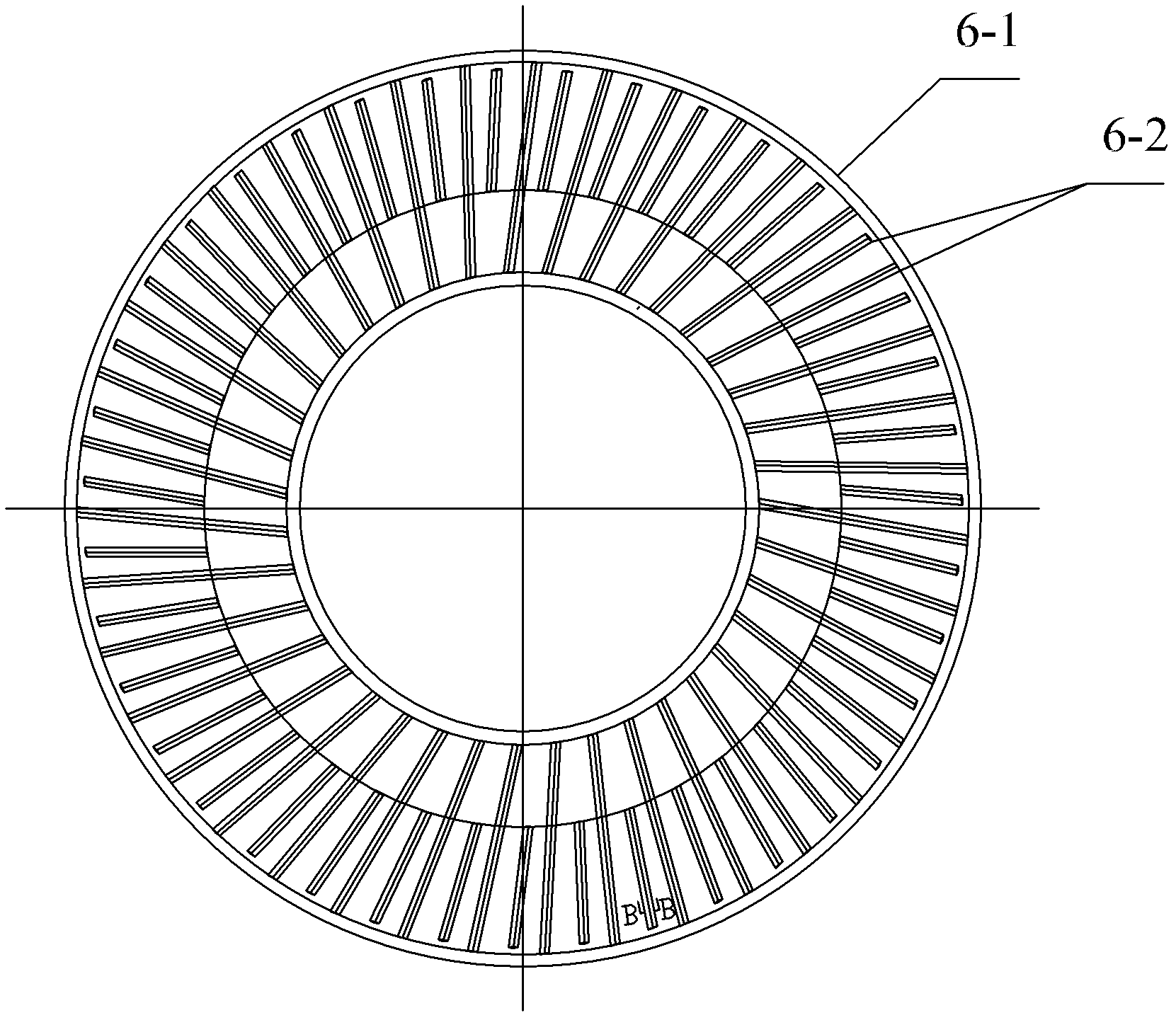

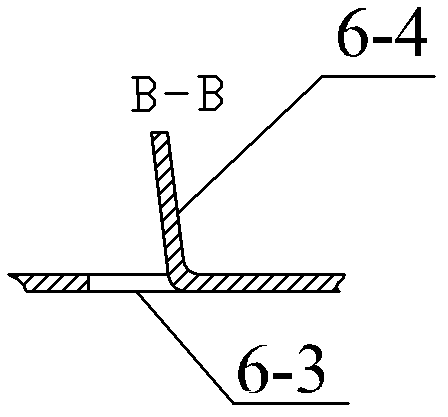

[0015] Such as figure 1 As shown, the silicone oil damper includes a silicone oil damper housing 1, an inertia block 3, a cover plate 5, and a bearing belt 4. The center of the silicone oil damper housing 1 is a through hole 7 that is inserted into the crankshaft of the engine. A cavity is formed around the shock absorber housing 1 and the cover plate 5, and the inertia block 3 is accommodated in the cavity, and the bearing belt 4 axially separates the inertia block 3 from the silicone oil shock absorber housing 1 to avoid the two Contact leads to abrasive damage. A limit ring 2 is spaced between the inertia block 3 and the silicone oil shock absorber housing 1 , and the limit ring 2 radially separates the inertia block 3 from the silicone oil shock absorber housing 1 .

[0016] Silicone oil is injected into the gap between the inertia block 3 and the silicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com