Switch valve driven by magnetostrictive actuator

A magnetostrictive and giant magnetostrictive technology, applied in valve details, valve devices, engine components, etc., can solve the problems of low driving efficiency, poor control accuracy, poor reliability, etc., to achieve compact structure, reduce the number, reduce mechanical Effects of friction and clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described in detail below in conjunction with the accompanying drawings.

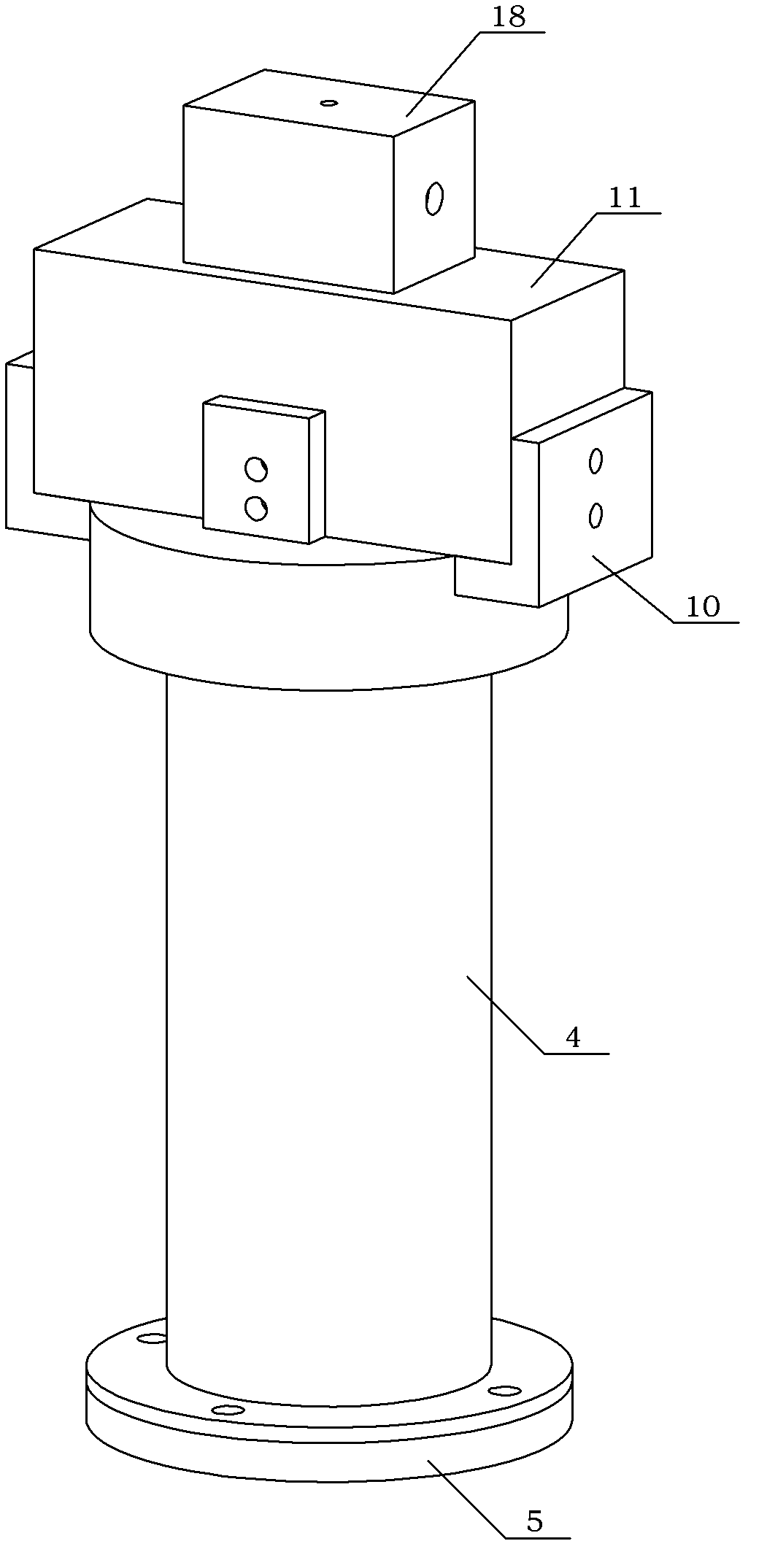

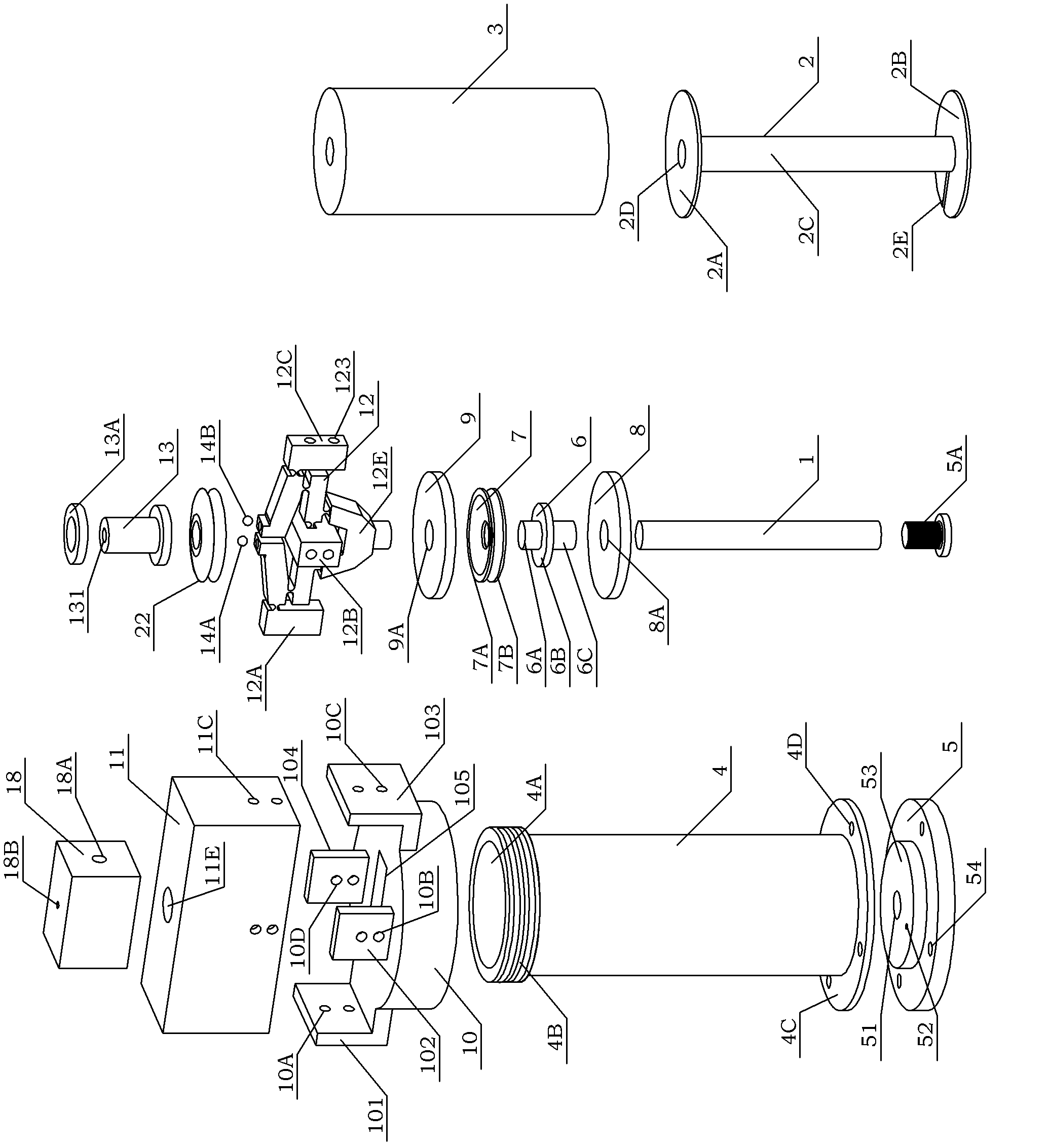

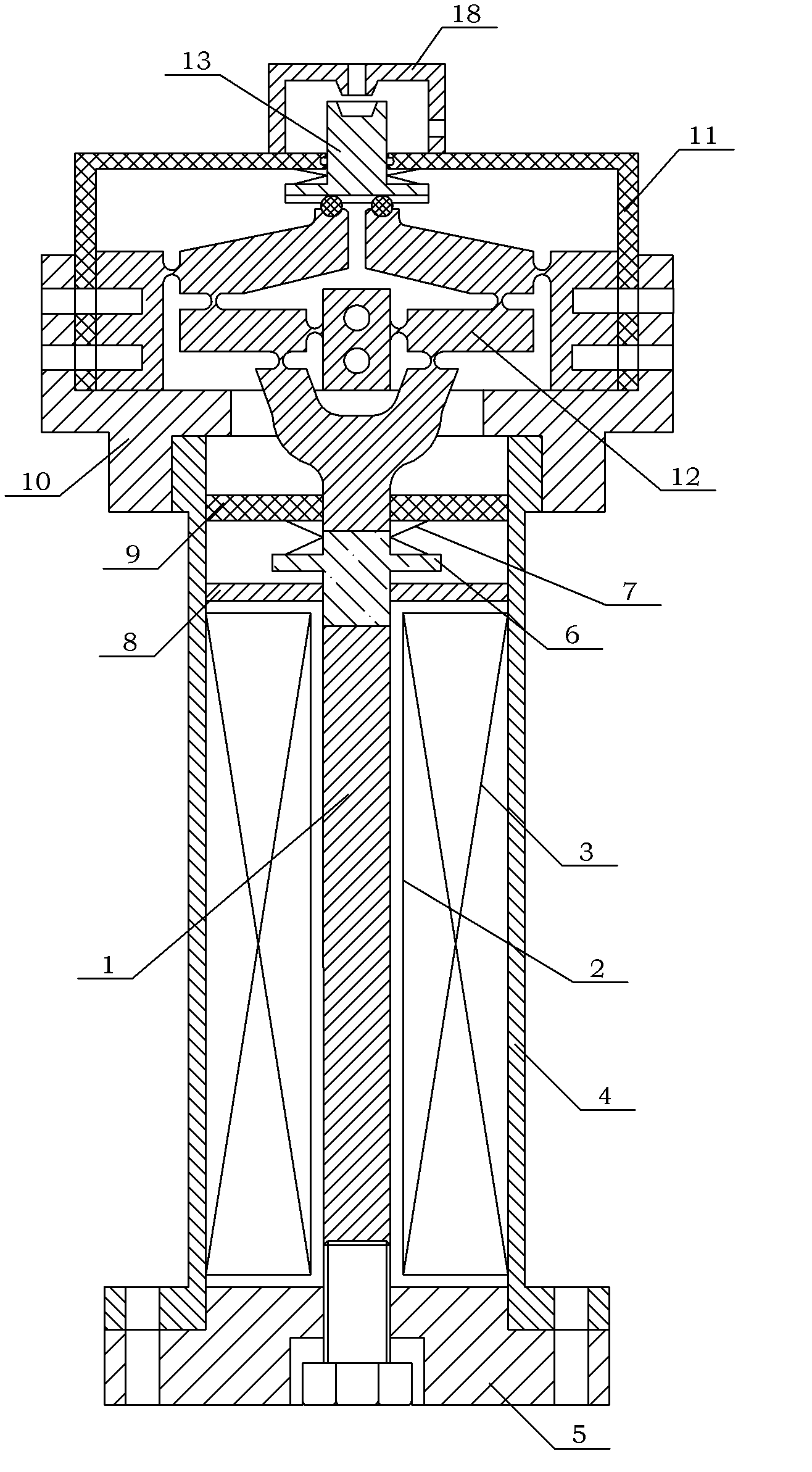

[0065] see figure 1 , Figure 1A , Figure 1B As shown, a switching valve driven by a magnetostrictive actuator of the present invention includes a giant magnetostrictive rod 1, a bobbin 2, an excitation coil 3, an outer sleeve 4, a chassis 5, a preload Bolt 5A, ejector rod 6, preload disc spring 7, return disc spring 19, limit plate 8, pressure plate 9, valve seat 10, valve housing 11, stroke amplifier 12, valve core 13, A ball shaft 14A, B ball Shaft 14B, valve body 18; wherein, giant magnetostrictive rod 1, coil bobbin 2 and excitation coil 3 form a drive unit; pre-compressed disc spring 7, reset disc spring 19, ejector rod 6, limit plate 8, pressure plate 9, The valve casing 11 , the stroke amplifier 12 , the valve core 13 , the A ball shaft 14A and the B ball shaft 14B form a transmission unit. The outer sleeve 4, the chassis 5, the pre-tightening bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com