Electromagnetic induction heating device for optical fiber fused biconical taper (FBT)

A technology of electromagnetic induction heating and melting taper, which is applied in the direction of induction heating device, induction heating, optical waveguide coupling, etc., to achieve the effect of improving quality, no environmental pollution, and realizing automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

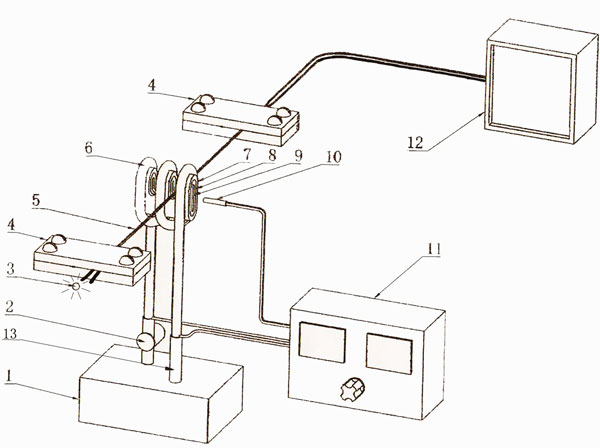

[0032] The present invention will be described in detail below in conjunction with the drawings.

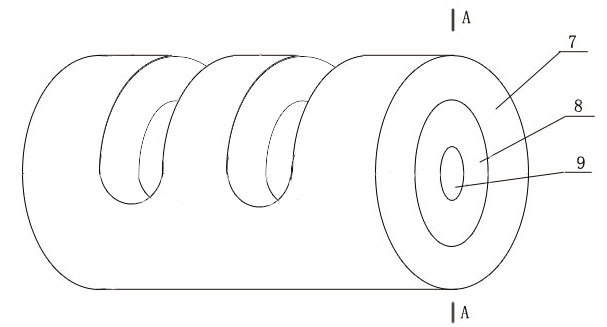

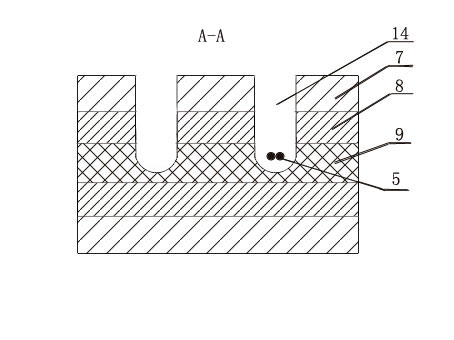

[0033] Such as figure 1 As shown, the present invention mainly includes a heating element 9, a shell containing the heating element (composed of a heat preservation shell layer 8 and an insulating shell layer 7), and an electromagnetic induction generator coil 6 surrounded by the heating element shell, which is connected to the induction generator coil The AC power supply 11, the medium circulation cooling system connected with the induction generator coil (consisting of the cooling circulation flow medium storage tank 1, the pressure pump 2, and the insulating pipe 13), and the system for measuring the temperature of the heating element (by Temperature probe 10 and temperature display control system 11). In addition, there are signal light sources 3 used to detect the tapering of the optical fiber, the movable clamp 4 used to clamp the fixed optical fiber, the optical fiber 5 in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com