Magnetic integrated double inductor

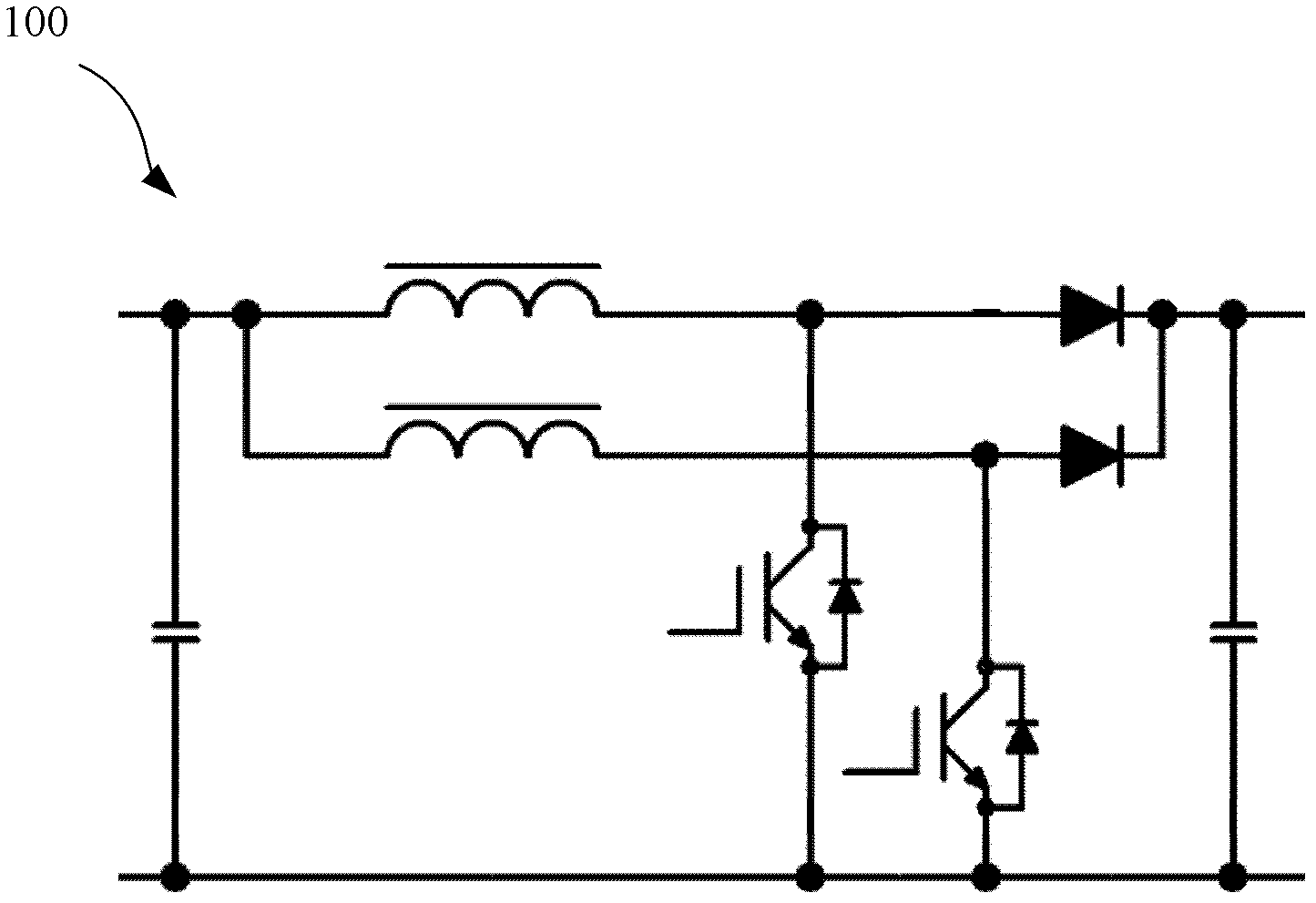

A dual-inductance, magnetic integration technology, applied in the field of inductors, can solve problems such as large circuits, and achieve the effect of suppressing the generation of high-order harmonics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

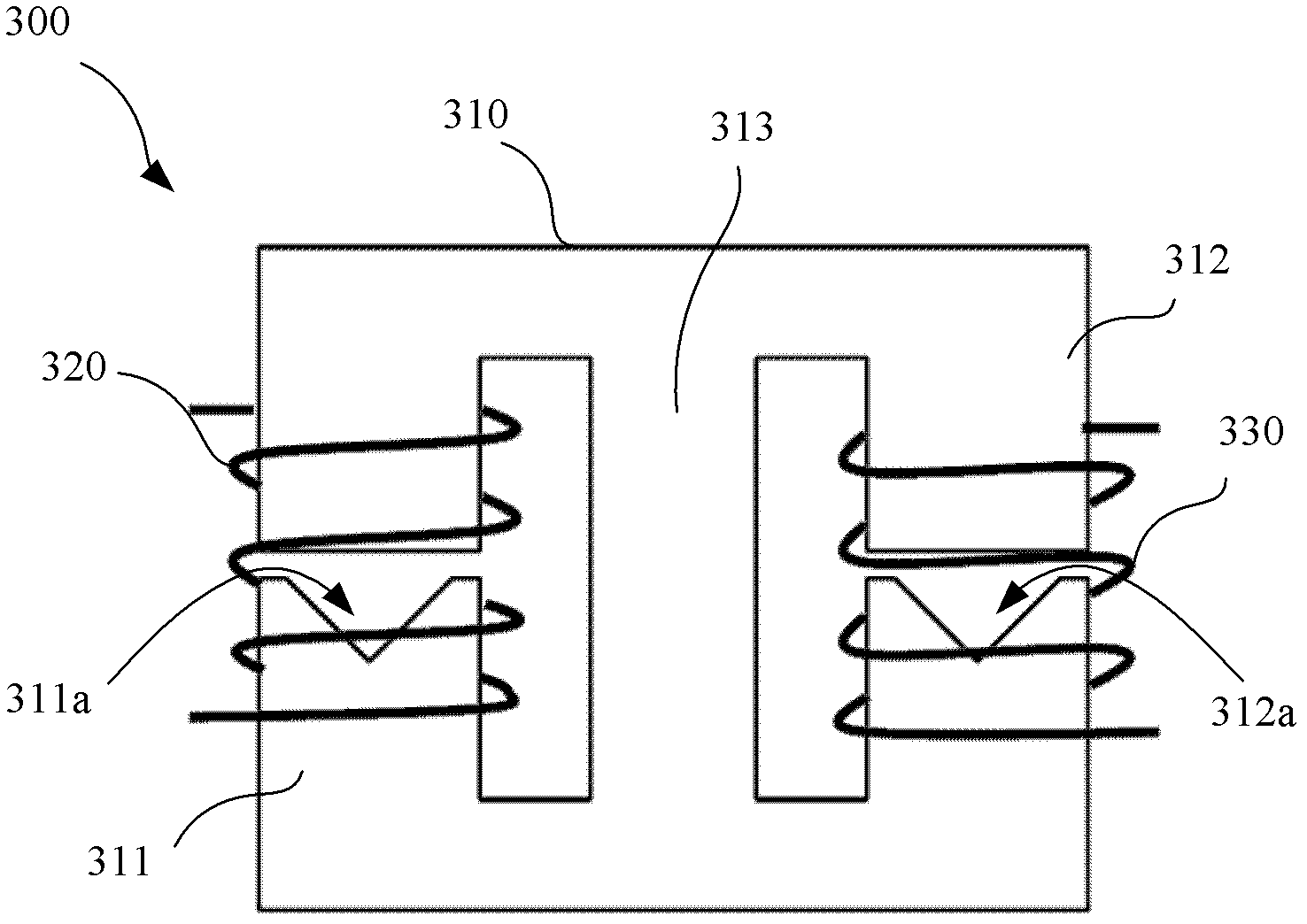

Embodiment Construction

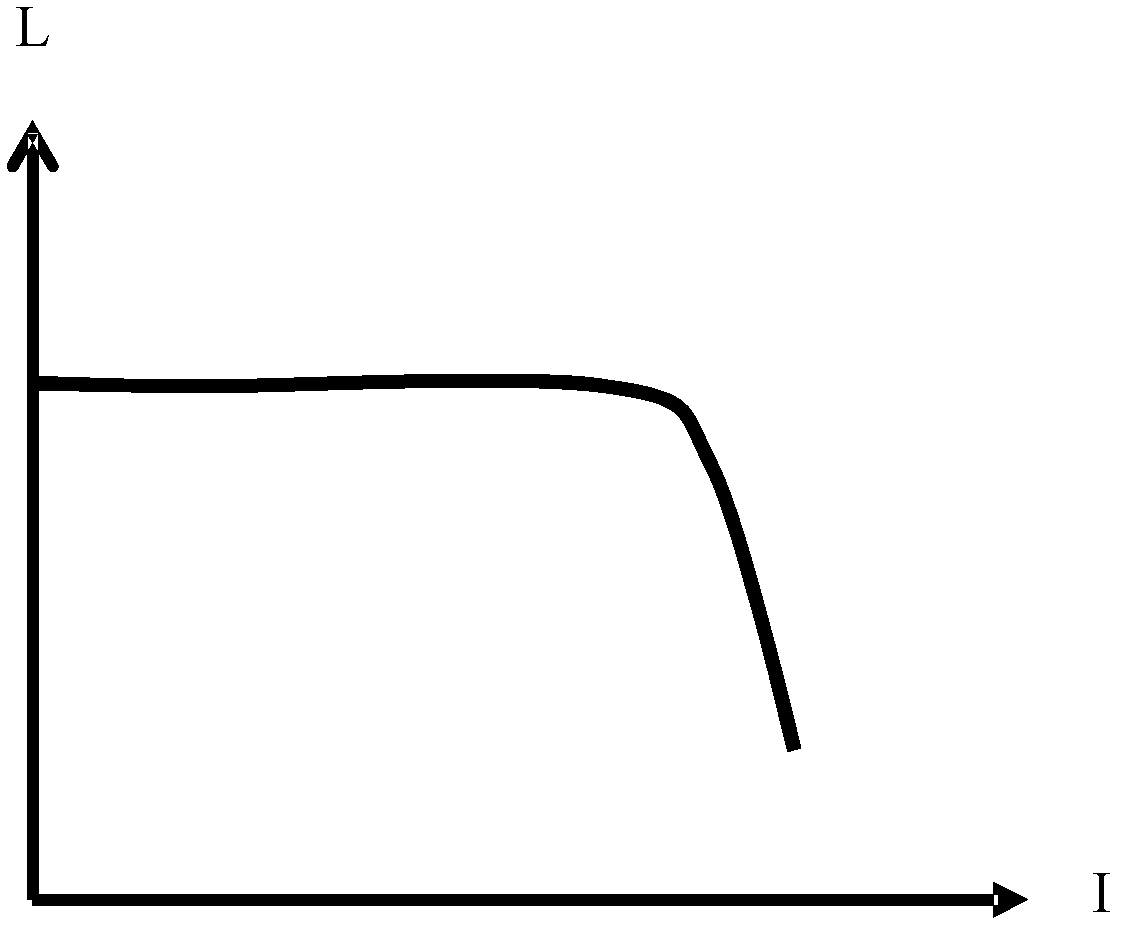

[0023] The inductance value of an inductor is usually described by the following formula:

[0024] L=μ 0 mu r N 2 A / l

[0025] Among them, L is the inductance, the unit Henry (H); μ 0 Permeability of free space = 4π*10 -7 H / m; μ r is the relative magnetic permeability of the core material; N is the number of turns; A is the cross-sectional area of the surrounding, in square meters (m 2 ); l is the length of the coil, in meters (m).

[0026] Due to the existence of the air gap in the inductor structure, the equivalent value of the relative permeability of the magnetic core material that determines the size of the inductance is greatly reduced, thereby making the inductance value smaller. According to this principle, if the core material with a smaller cross-sectional area is used in the air gap space of the air part, on the magnetic circuit inside the inductor coil, the same magnetic flux has to pass through the narrow core space, so that this part is small. area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com