Method for optimizing magnetic suspension permanent magnet planar motor magnetic steel array parameter

A permanent magnet plane, magnetic steel array technology, applied in electrical digital data processing, holding devices with magnetic attraction or thrust, magnetic circuits, etc., can solve the problems of poor high-order harmonic effect, etc. , taking into account complexity and accuracy, and optimizing the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

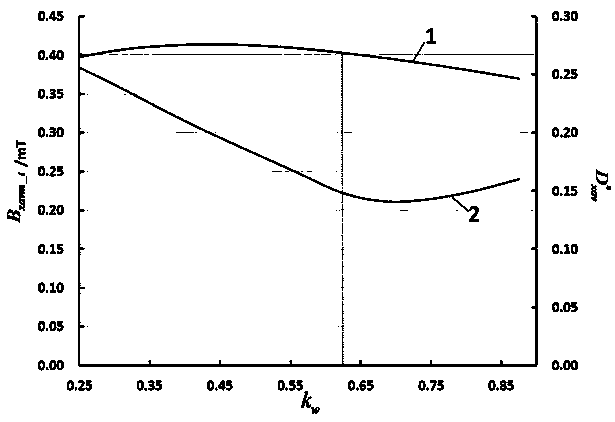

Embodiment Construction

[0022] The invention adopts the average fundamental wave amplitude to set the expected air-gap magnetic density, and establishes a mathematical model of the expected air-gap magnetic density; uses the average fundamental wave amplitude on different levels to calculate the total average of the expected magnetic density within the effective magnetic field space height range Based on the fundamental wave amplitude, the average relative mean square error between the actual magnetic density and the expected air-gap magnetic density is calculated through the air-gap magnetic density harmonic model; according to "the total average fundamental wave amplitude of the expected magnetic density should be as large as possible, the actual magnetic density and The average relative mean square error of the expected magnetic density should be as small as possible" to determine the magnetic steel parameters. details as follows:

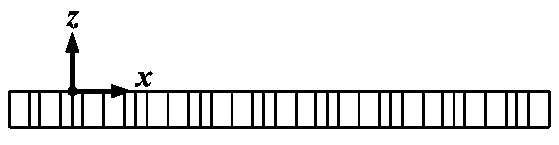

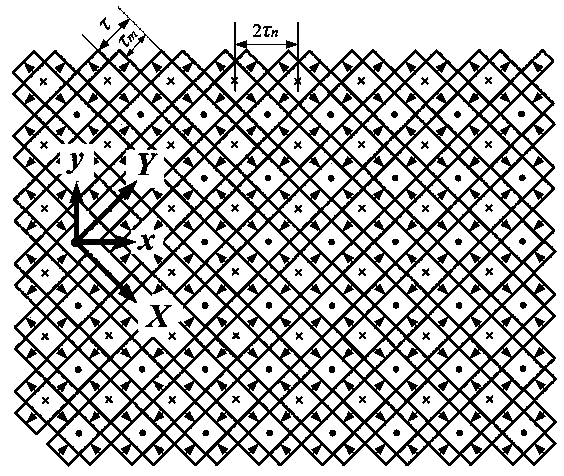

[0023] Such as figure 1 and figure 2 As shown, the stator of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com