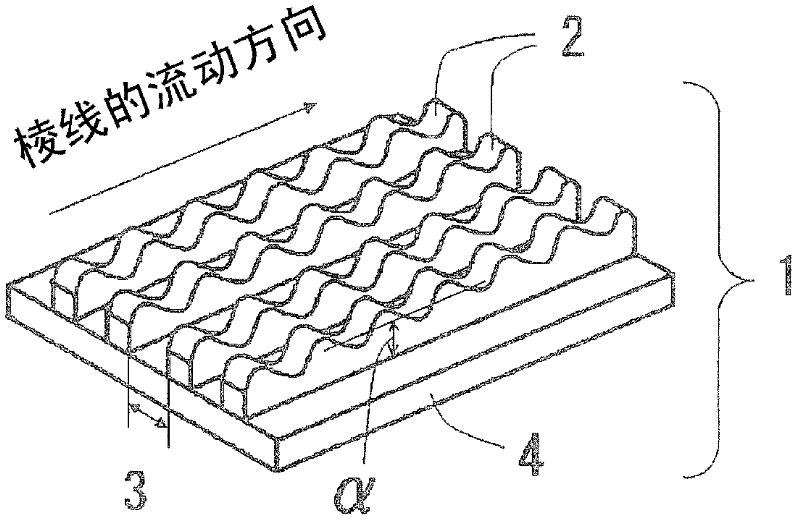

Newton ring preventing sheet, and touch panel using same

A Newton ring and touch screen technology, applied in transportation and packaging, the conductive layer on the insulating carrier, the input/output process of data processing, etc., can solve the problems of flashing glare and color screen glaring, and achieve good visibility and anti-corrosion Excellent effect of Newton's ring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

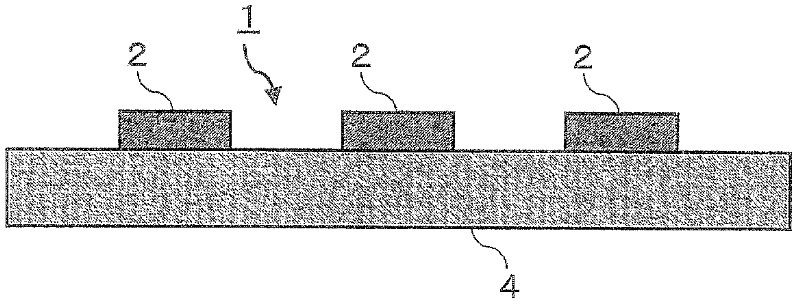

Embodiment 1

[0107] A 4 mm-thick copper plate having a smooth surface was cut using a diamond engraving knife to prepare a mold. Into the prepared mold, 50 parts by weight of an acrylic monomer (methyl methacrylate: Wako Pure Chemical Industries, Ltd.) and a polyfunctional acrylic monomer (NKェェステル A-TMPT-3EO : Shin Nakamura Chemical Industry Co., Ltd.) 45 parts of the photopolymerization initiator (Irgacure 184: Ciba Seika Japan Co., Ltd.) 5 parts of the mixed solution, covered with a 100 μm thick polyester film (cosmosh ィ ィン A4300: Toyobo Co., Ltd.), roll The resin is evenly stretched so that no air bubbles remain, so that the resin and the polyester film are tightly bonded.

[0108] In this state, irradiate 1500mJ / cm from the side of the polyester film with a metal halide lamp 2 After the UV-curable resin is cured, the polyester film and the resin are peeled off from the mold, the shape of the mold is faithfully transferred, and the anti-Newton ring sheet of Example 1 ( Figure 5 anti-...

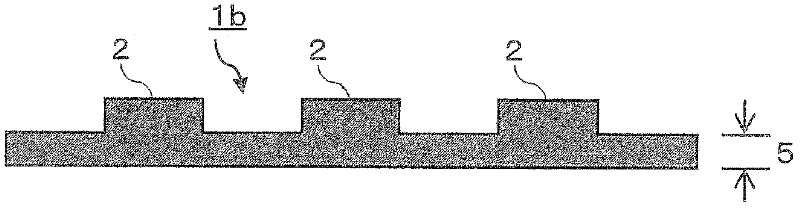

Embodiment 2~10

[0110] The anti-Newton ring sheets of Examples 2-10 were produced similarly to Example 1 except having cut|disconnected the copper plate using the cutting conditions different from Example 1. Table 1 shows the structure of the structure row of the anti-Newton ring sheets of Examples 2-10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com