Control method for super extra gravity settling separator

A control method and sorting machine technology, applied in centrifuges and other directions, can solve the problems of continuous production, high labor intensity and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

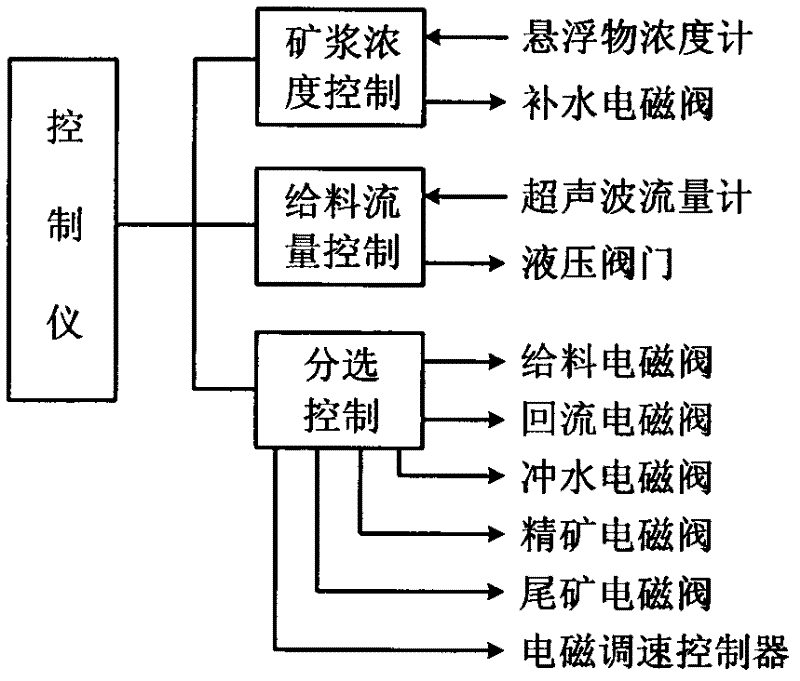

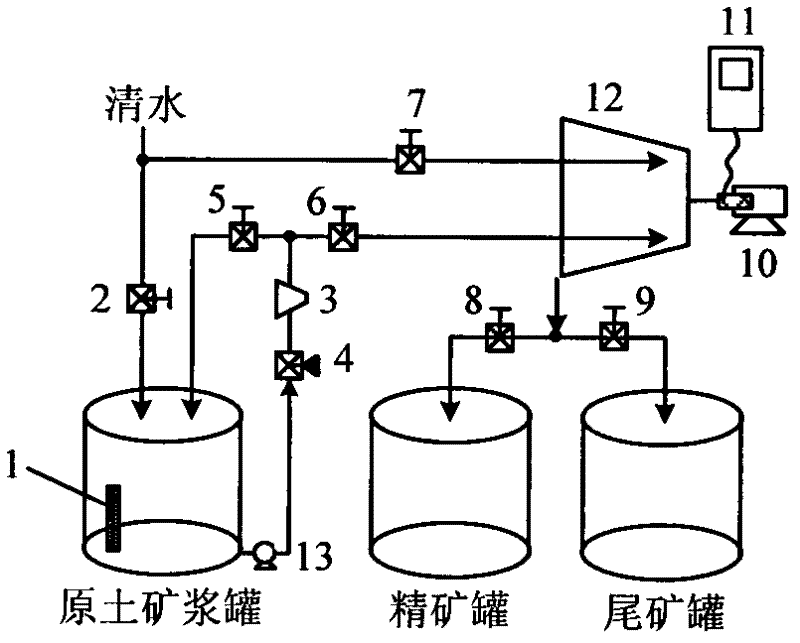

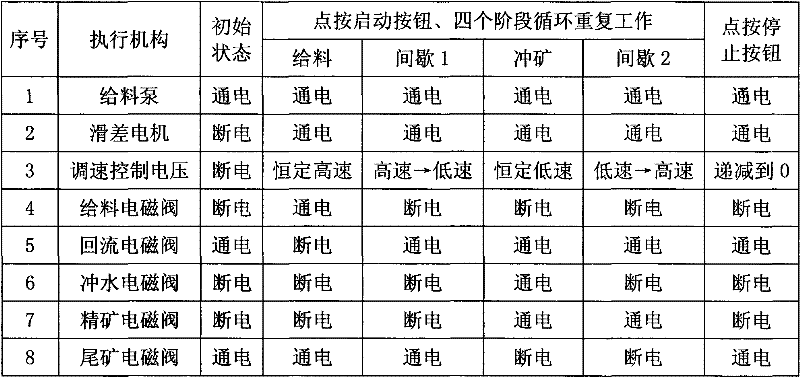

[0029] figure 1 It is the principle block diagram of the control method of the supergravity sedimentation separator, which specifically includes pulp concentration control, feed flow control, sorting control and controller, and the controller is respectively connected to the pulp concentration control and feed flow control and sorting control, the pulp concentration control includes a suspended solids concentration meter and a water replenishment solenoid valve, the feed flow control includes an ultrasonic flow meter and a hydraulic valve, and the sorting control includes a feed pump, a feed electromagnetic Valves, return solenoid valves, flushing solenoid valves, concentrate solenoid valves, tailings solenoid valves, slip motors and solenoid speed controllers.

[0030] The pulp concentration control is based on the diatomite pulp co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com