Stop iron mechanism of cutting machine

A cutting machine and iron adjustment technology, which is applied in metal processing and other directions, can solve the problems of stuck, high precision parts processing and assembly, and impractical synchronous adjustment of four iron blocks, and achieves simplified structure, processing and assembly. The effect of easy to ensure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

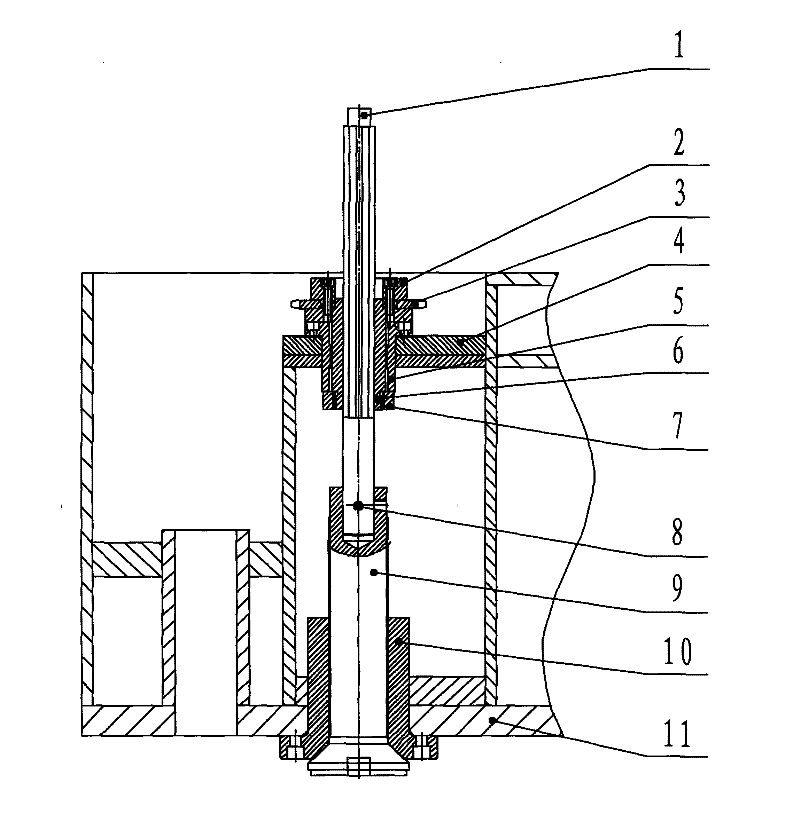

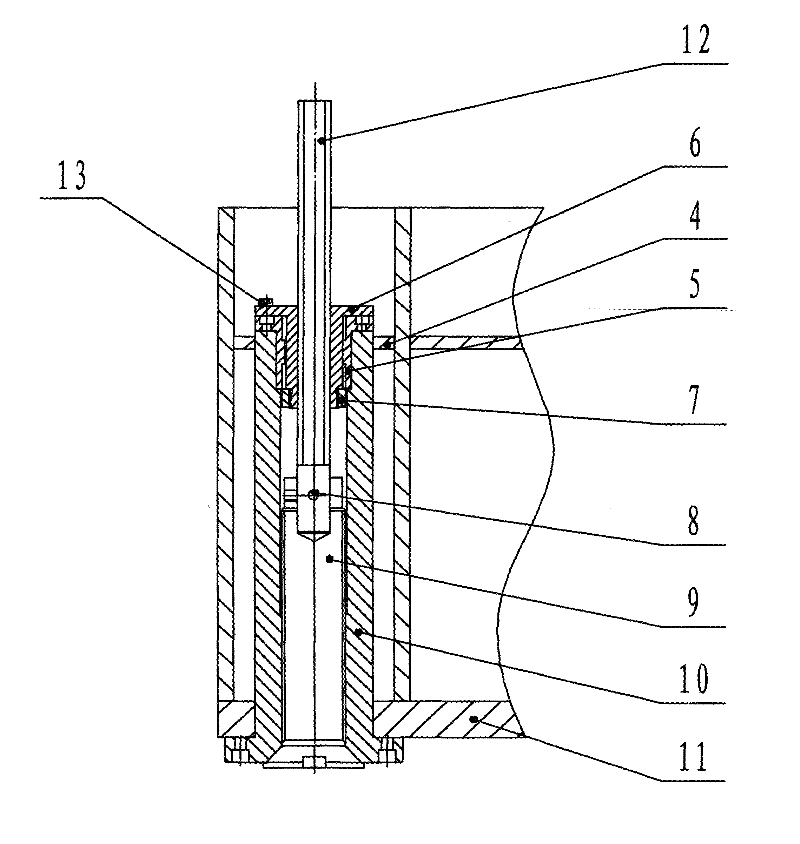

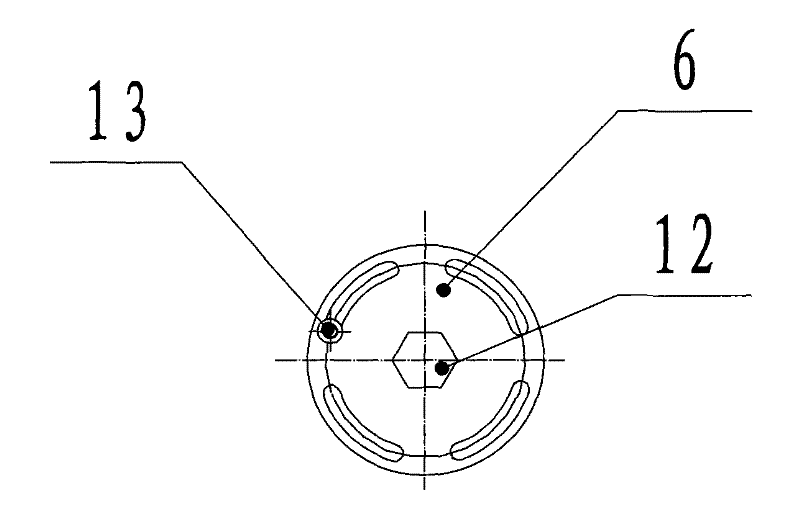

[0014] exist figure 1 Among them, the upper fixing seat 5 and the lower fixing seat 10 are respectively positioned and installed on the upper side plane 4 of the upper template and the lower side plane 11 of the upper template, the sliding sleeve 6 and the inner hole of the upper fixing seat 5 are slidingly fitted, and the locking nut 7 restricts the sliding sleeve 6 Axial movement, the spline shaft 1 passes through the sliding sleeve 6 and is fixed by the positioning pin 8 and the iron stop 9, the iron stop 9 and the lower fixing seat 10 are threadedly connected, and the rotating spline shaft 1 can drive the iron stop 9 in the lower fixing seat 10 Rotate to realize the axial adjustment of the stopper 9. The sprocket 3 is fixed by the sprocket fixing block 2 and the sliding sleeve 6, which can realize the synchronous adjustment of multiple stoppers. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com