Variable displacement oil pump

A displacement machine, a variable technology, applied in the direction of lubricating pumps, mechanical equipment, engine components, etc., can solve the problems of reducing pressure, not meeting energy saving and emission reduction, and difficult displacement, so as to reduce energy loss and reduce hydraulic power And mechanical power, efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

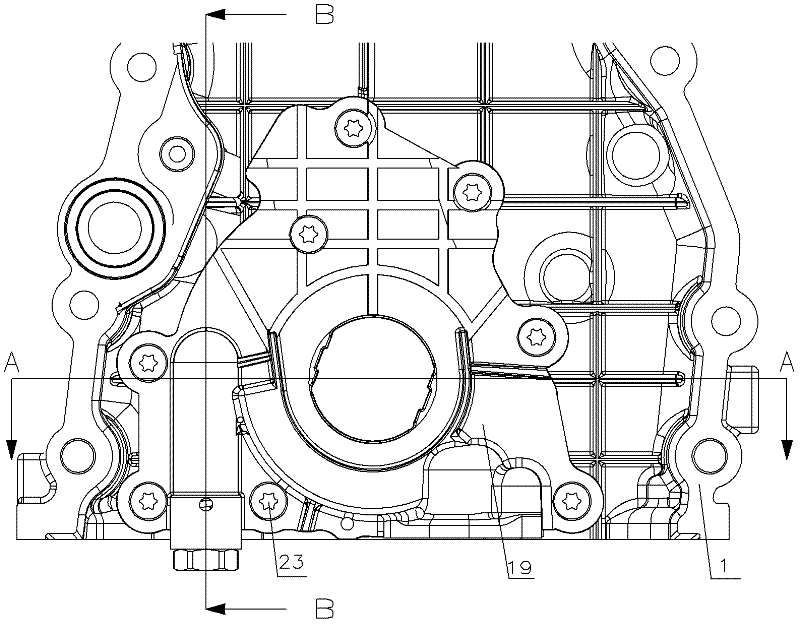

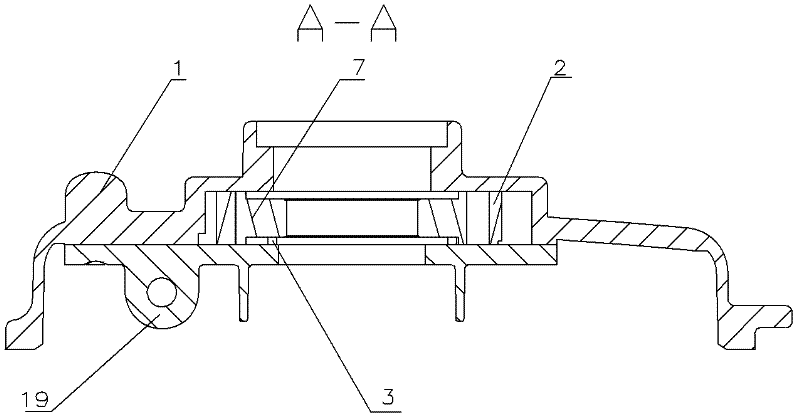

[0040] see figure 1 , the variable displacement oil pump for automobile engines involved in the present invention includes a pump body 1 and a pump cover 19 , and the pump body 1 and the pump cover 19 are connected by bolts 23 .

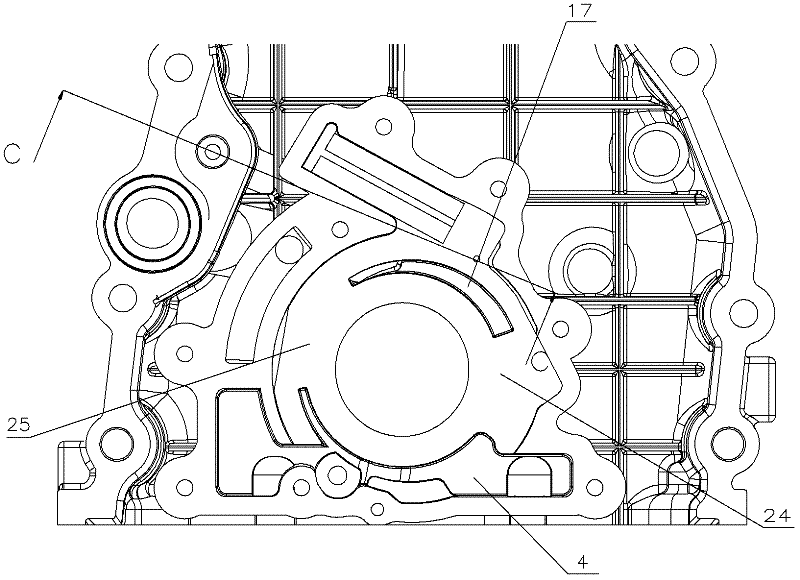

[0041] see Figure 8 (combined Figure 6 , Figure 7 ), which is a structural schematic diagram of the variable displacement oil pump for automobile engine involved in the present invention, and is also an initial state diagram. Including the pump body 1, the pump body 1 is provided with an inner chamber 10, the inner chamber 10 is provided with a stator 2, the stator 2 can rotate relative to the pump body 1 in the inner chamber 10, and the rotation center of the stator 2 is not at the stator 2 at the geometric center of . The stator 2 is provided with a rotor 7 connected to the engine crankshaft, the stator 2 and the rotor 7 are eccentrically arranged, and the rotor 7 is provided with a plurality of blades 5 on the circumference, and the ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com