Six-degree of freedom vibration absolute measuring method based on triaxial acceleration sensor array

A sensor array, axis acceleration technology, applied in multi-dimensional acceleration measurement, velocity/acceleration/shock measurement, acceleration measurement using inertial force, etc. Guarantee, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

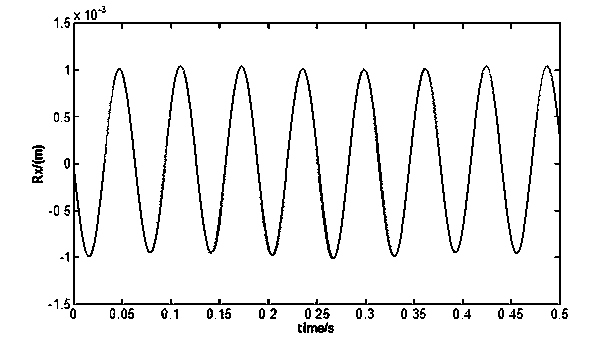

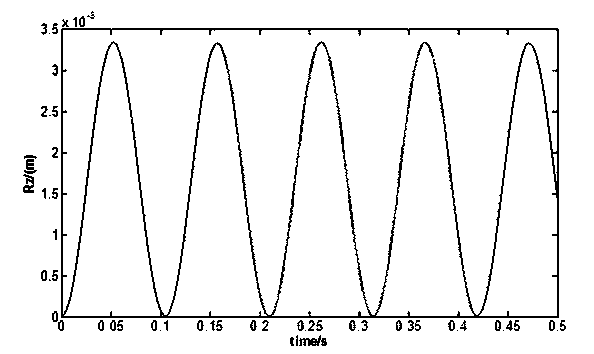

[0056] An absolute test method for six-degree-of-freedom vibration based on a three-axis acceleration sensor array is actually applied to the absolute test for six-degree-of-freedom vibration of a moving body vibration table.

[0057] The test method is carried out in the following sequence of steps:

[0058] (1) Build a capacitive acceleration sensor array

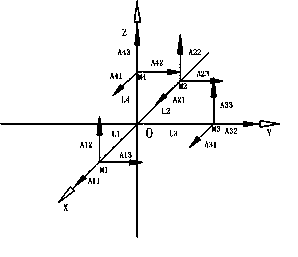

[0059] Select the measurement reference point O on the vibration table as the coordinate center, construct a three-dimensional coordinate system O-XYZ, and set six directions along the coordinate axis: X positive, X negative, Y positive, Y negative, and Z positive , Z negative direction is the reference direction.

[0060] In X positive direction, X negative direction, Y positive direction, and Z positive direction, respectively select points M1, M2, M3, and M4 with a distance of 1 meter from point O. Install capacitive three-axis acceleration sensors at the above four points, and the center of the capacitive three-axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com