Electric junction box

A technology for electric junction boxes and shells, which is applied in the field of electric junction boxes, and can solve problems such as cracks, damages, and warping of bolt fixing parts of electric junction boxes, so as to prevent cracks and damages, achieve mutual reinforcement effects, and improve deformation The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described below with reference to the drawings.

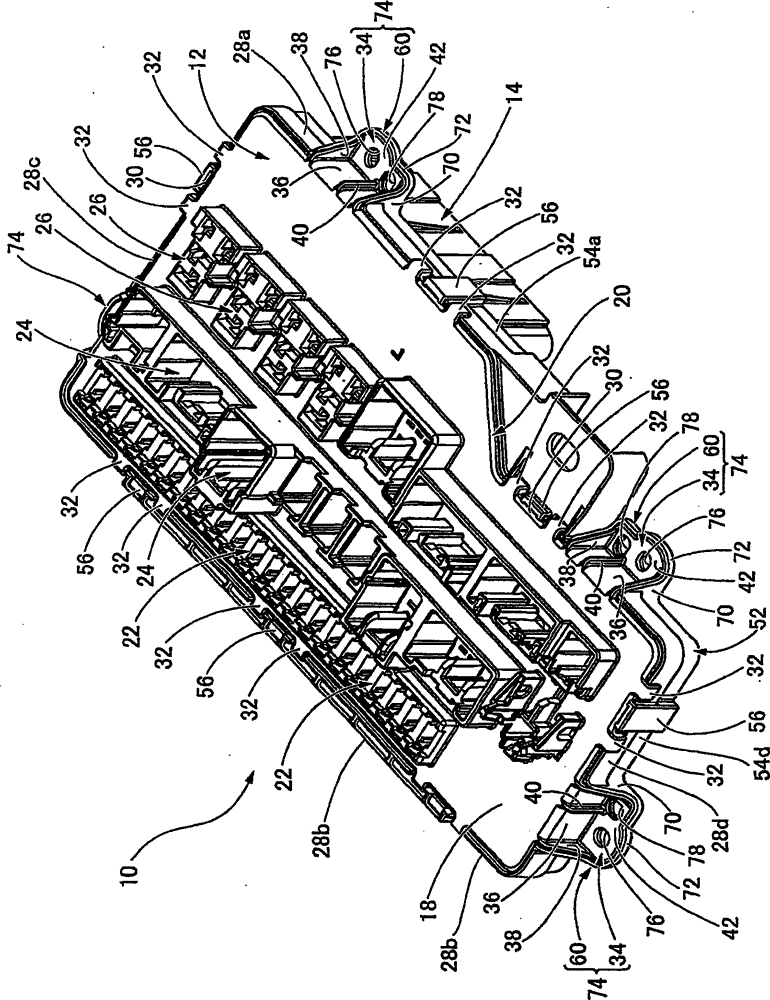

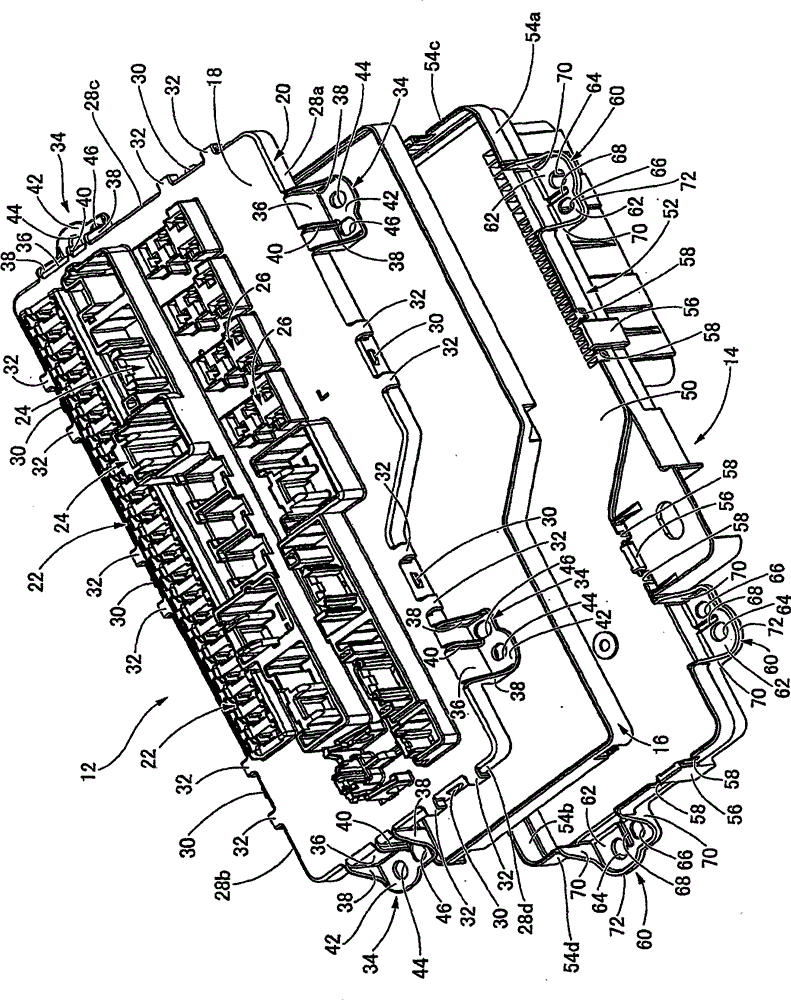

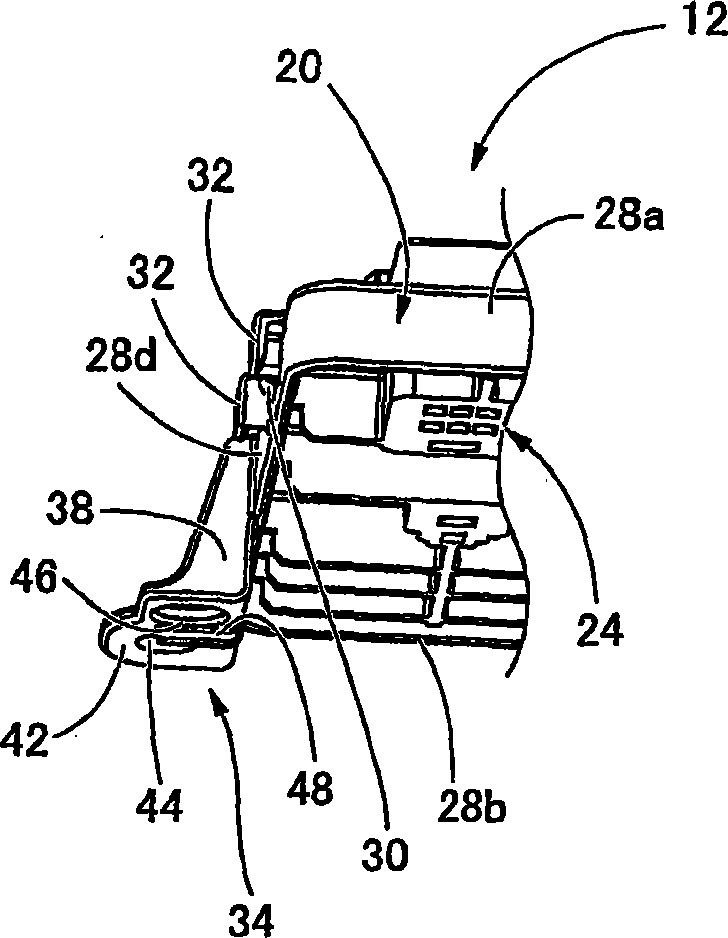

[0023] first reference figure 1 and figure 2 , figure 1 and figure 2 An electrical junction box 10 for an automobile according to an embodiment of the present invention is shown in a perspective view in an assembled state and a perspective view in an exploded state, respectively. from its figure 1 and figure 2 As clearly seen in , the electrical junction box 10 includes an upper case 12 as a first case and a lower case 14 as a second case, and these cases are combined with each other in an up-down direction, thereby constituting the electrical junction box 10 . In addition, inside such an electrical junction box 10 is formed a predetermined accommodation space in which the circuit body 16 is accommodated by assembling unillustrated bus bars, single core wires, and connection terminals on an insulating plate. And constitute the internal circuit. In the following descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com