Frameless sterilization processing system

A processing system and sterilization tank technology, applied in the field of sterilization processing equipment, can solve problems such as low operation efficiency and a large number of manual operations, and achieve the effect of avoiding low efficiency and avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

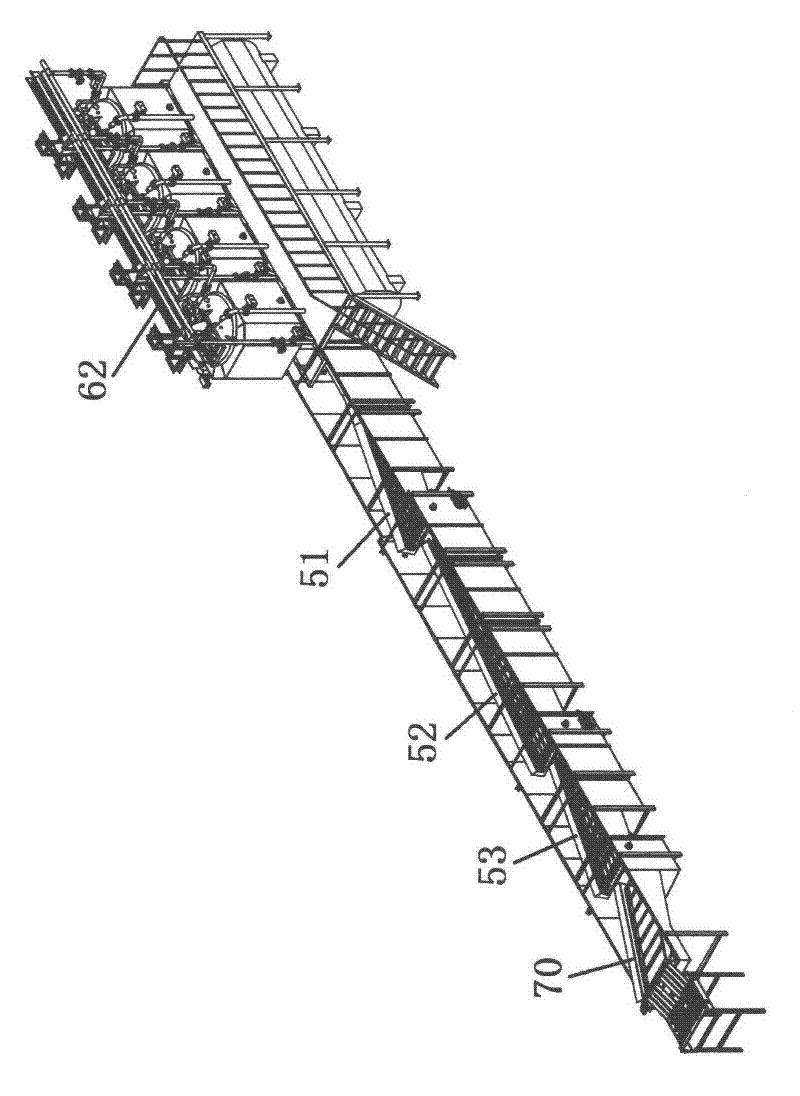

[0020] Such as figure 1 As shown, the frameless sterilization treatment system of the present invention includes at least one retort tank, a conveying device for materials to be sterilized arranged above the retort tank, and a sorting device for materials to be sterilized arranged behind the retort tank.

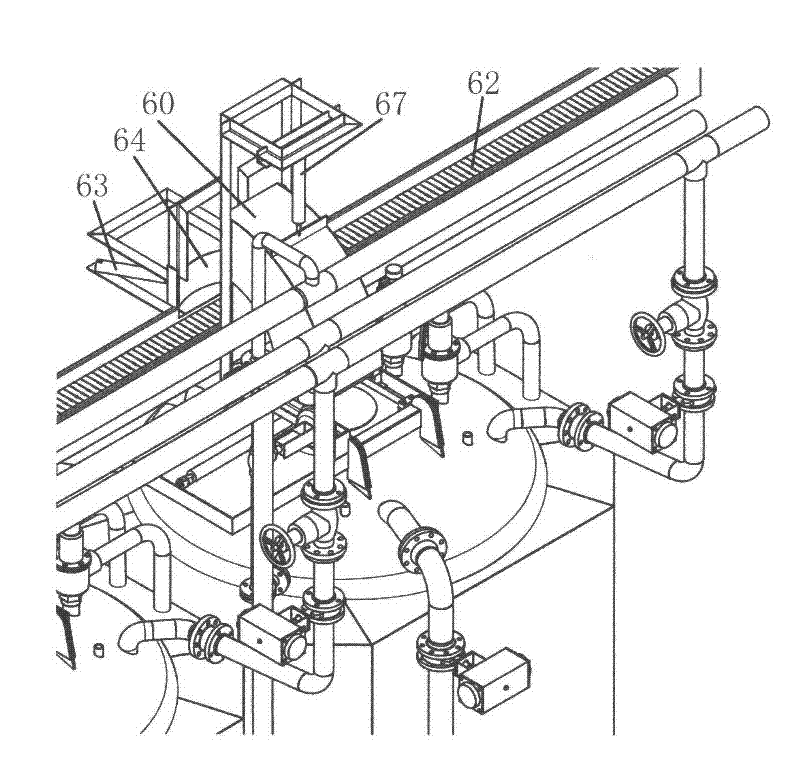

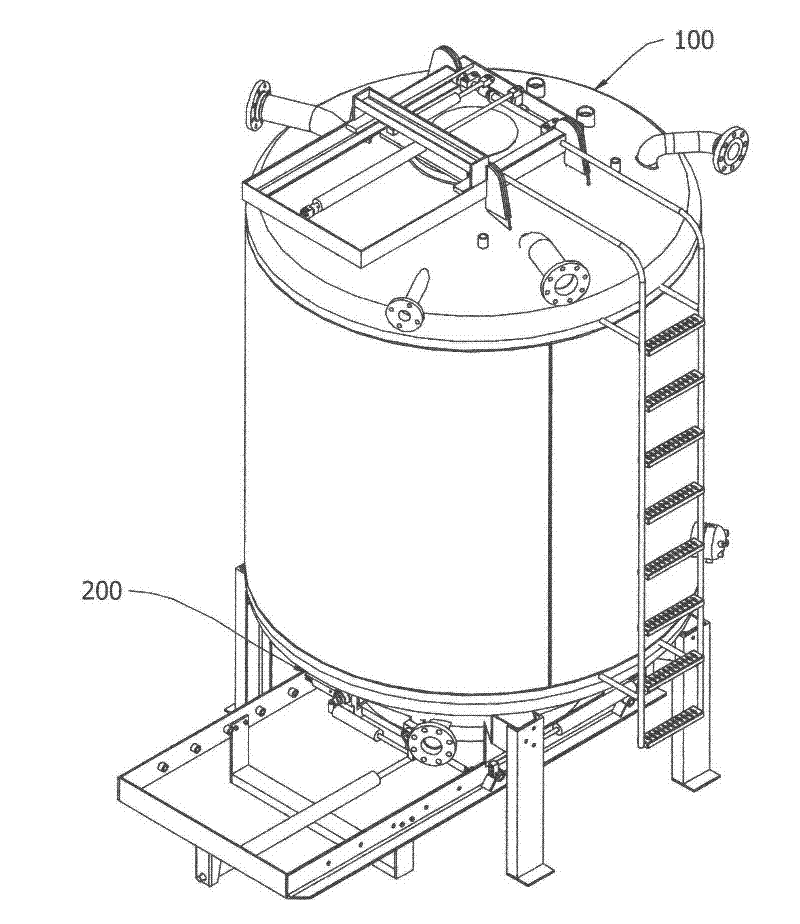

[0021] Such as figure 2 As shown, the conveying device of the material to be sterilized in the retort tank of the present invention includes a conveyor belt 62, four feeding parts arranged above the conveyor belt, and retort tanks corresponding to the feeding parts respectively. The sterilization tank is arranged under the feeding part, and the upper part of the sterilization tank is provided with an upper cover structure.

[0022] The four feed components are identical in construction. The first feeding part includes a feeding cylinder 60 arranged on one side of the conveyor belt 62 , and a guide baffle 64 arranged on the other side of the conveyor belt 62 .

[0023] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com