3-methyl-3-butenyl-1-alcohol production method

A production method and technology of butene, applied in the direction of organic chemistry, isomerization preparation, etc., can solve the problems of large investment and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

[0014] The isomerization reactor is a φ25mm×1000mm stainless steel tubular reactor, the reaction tubes are respectively filled with φ5mm×5mm spherical palladium-containing catalyst 100ml, and the bottom of the reactor is filled with inert ceramic balls. The catalyst is Pd / SiO 2 , the Pd content is 40%, the rest is carrier, and the bulk density of the catalyst is 0.8g / ml.

[0015] The isopentenol containing organic chlorine is preheated and then pumped into the isomerization reactor from the top at a set rate, hydrogen enters the reactor through a gas distributor, and the raw material and hydrogen are mixed and then enter the catalyst bed for further processing. Isomerization reaction. The space velocity, temperature and hydrogen flow rate of the reaction were adjusted to the set values, and samples were taken from the outlet of the reactor for analysis.

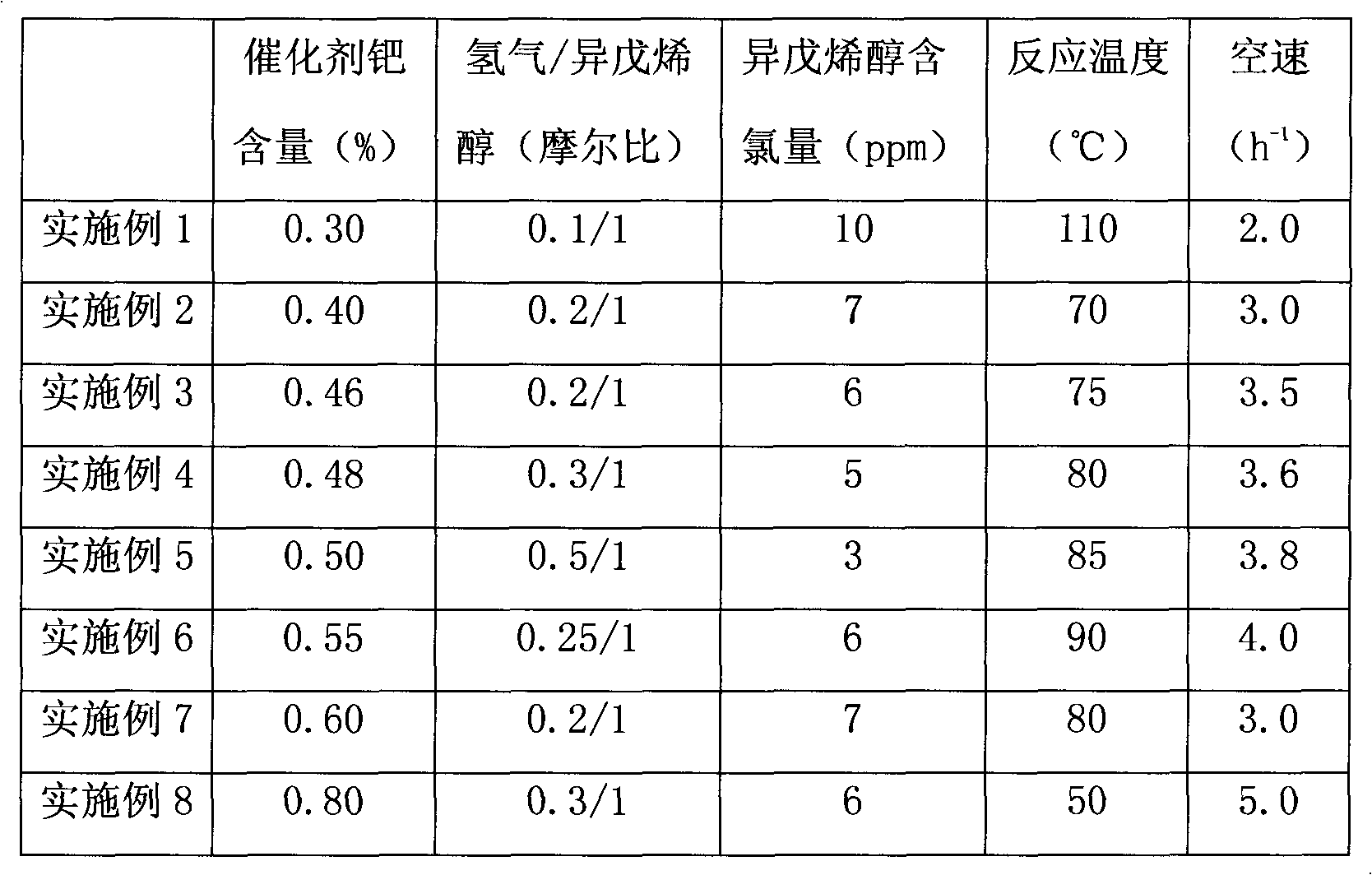

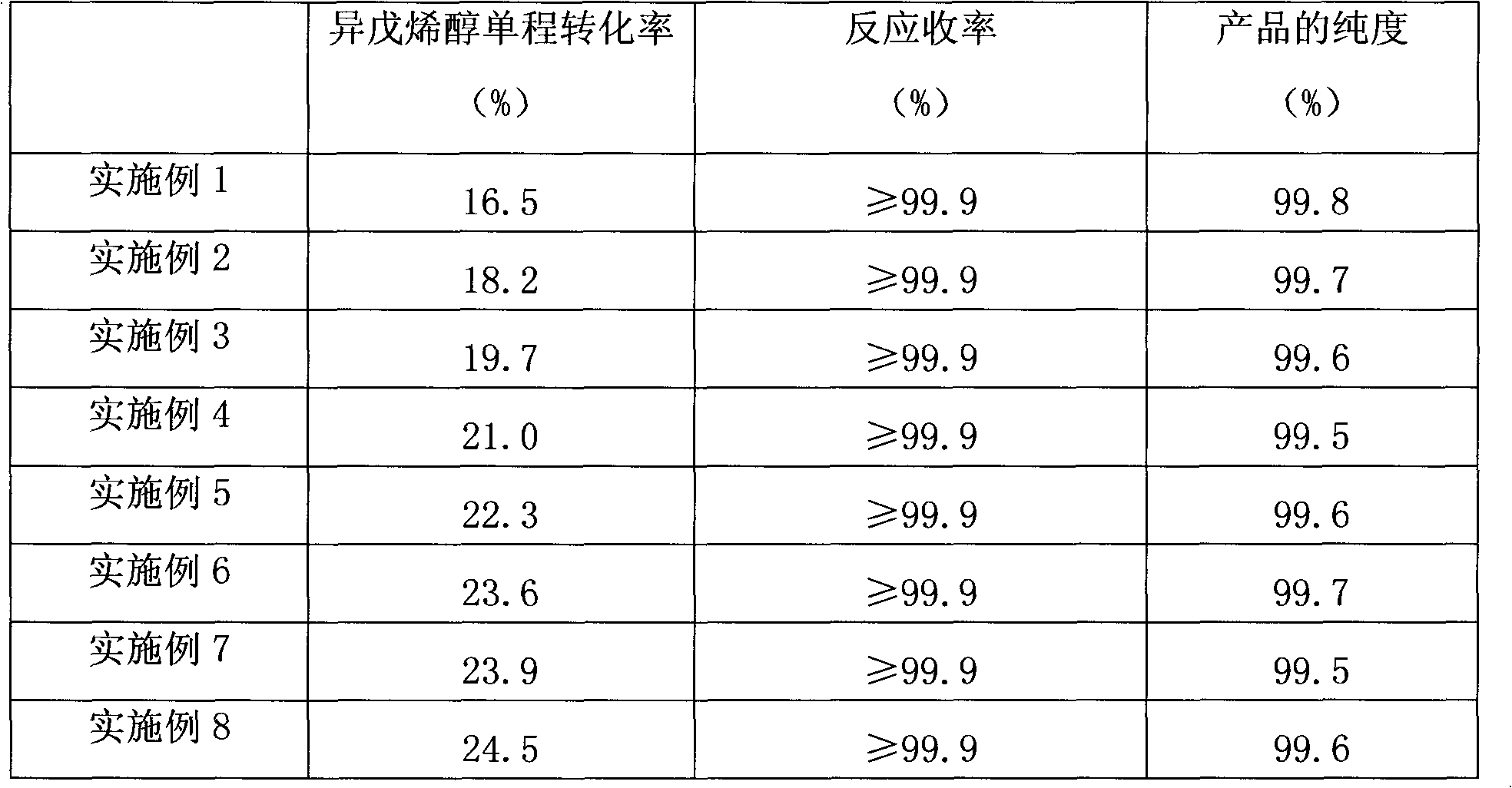

[0016] The reaction conditions of each embodiment are shown in Table 1, and the reaction results are shown in Table 2

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com