Stenotrophomonas M12 for degrading unsymmetrical dimethylhydrazine (UDMH) and method for degrading UDMH

A technology of oligotrophomonas and unsymmetrical dimethylhydrazine, which is applied in the field of oligotrophomonas maltophilia M12 and its degradation of unsymmetrical dimethylhydrazine, can solve the problem of low safety factor, high energy consumption, immature technology in application, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

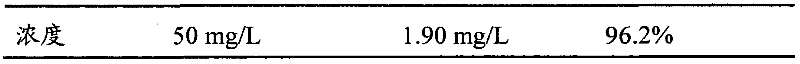

Embodiment 1

[0016] This embodiment provides a method for degrading unsymmetrical dimethylhydrazine by using Stenotrophomonas maltophilia M12, the method comprising the following steps:

[0017] Seed culture: inoculate the strain of Stenotrophomonas maltophilia M12 on the slant medium, and cultivate it at 28-32°C for 24 hours to obtain the slant culture; the composition of the above-mentioned slant medium: yeast extract 5-15g / L, Peptone 5~15g / L, (NH 4 ) 2 SO 4 5g / L and agar 15g / L.

[0018] Take the well-grown slant culture and inoculate it into a 250mL Erlenmeyer flask containing 100mL of seed medium, and culture it for 24 to 36 hours under the conditions of a shaker flask rotation speed of 190-220r / min and a culture temperature of 28-32°C to obtain seeds Culture medium; above-mentioned seed culture medium composition: yeast extract 5~15g / L, peptone 5~15g / L and (NH 4 ) 2 SO 4 5g / L.

[0019] Degradation of unsymmetrical dimethylhydrazine: Inoculate the seed culture solution into a ...

Embodiment 2

[0022] Seed culture: Inoculate the strain of Stenotrophomonas maltophilia M12 on the slant medium, and cultivate it at 30°C for 24 hours to obtain the slant culture; the composition of the above slant medium: yeast extract 10g / L, peptone 10g / L , (NH 4 ) 2 SO 4 5g / L and agar 15g / L.

[0023] Take the well-grown slant culture and inoculate it into a 250mL Erlenmeyer flask with 100mL of seed medium, and cultivate it for 24 hours under the condition that the rotation speed of the shaker flask is 200r / min and the culture temperature is 30°C to obtain the seed culture solution; the above-mentioned seed culture Base composition: yeast extract 10g / L, peptone 10g / L and (NH 4 ) 2 SO 4 5g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com