Power balance control method of frequency converter multi-motor dragging system and test device

A drag system, power balance technology, applied in the control of electromechanical transmission, motor generator control, electronic commutation motor control, etc., can solve the problem of relying on the performance of liquid viscous transmission and not reaching it.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

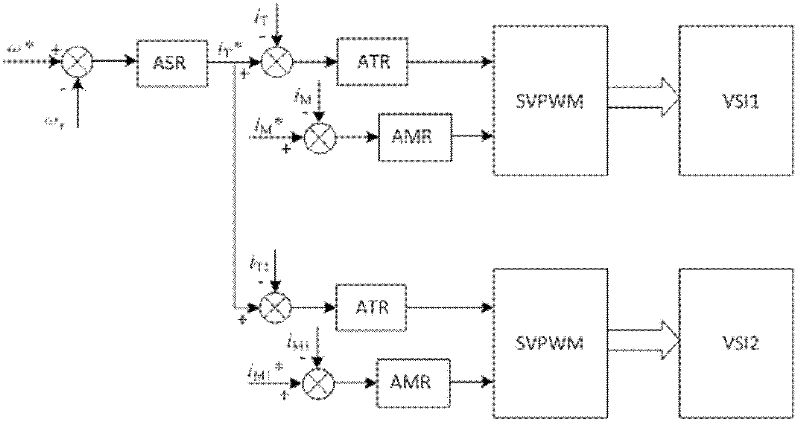

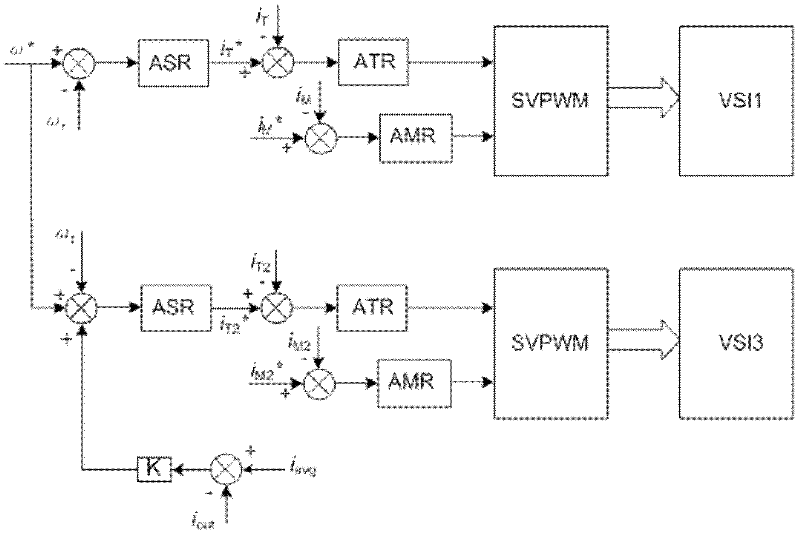

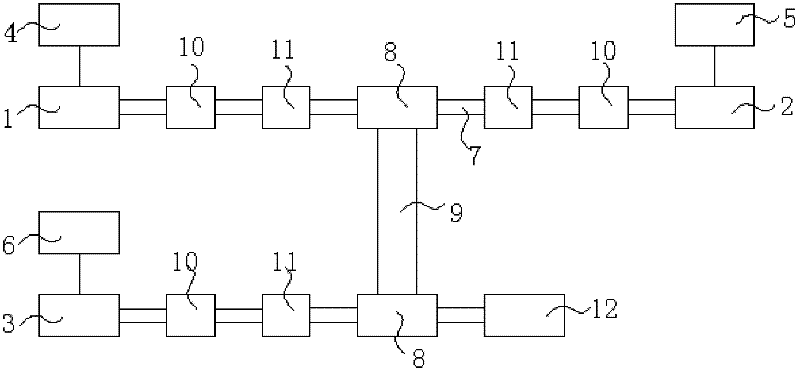

[0018] The power balance control method of the frequency converter multi-machine drive system of the present invention includes the following steps,

[0019] At the beginning, set a frequency converter as the main frequency converter, and determine a benchmark for power balance of the multi-motor drive system. Then set the slave inverter that is hard-connected with the drive motor of the main inverter as the first type of slave inverter. The hard-connected motor mentioned here is the motor that is coaxially connected with the drive motor of the main inverter; The slave frequency converter of the softly connected motor is the second type of slave frequency converter, and the softly connected motor mentioned here refers to the motor connected with the main frequency converter through a belt or other flexible means.

[0020] The first type of slave inverter tracks the torque of the master inverter, and the first type of slave inverter adjusts the torque of the motor connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com