Method for tensioning pre-stressed reinforcement of ballast-less transition sleeper of ballast-less track

A technology of prestressed steel bars and ballastless tracks, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of high labor intensity of workers, occurrence of slipping and broken wires, and excessive material waste, saving material costs and reducing Weight, space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

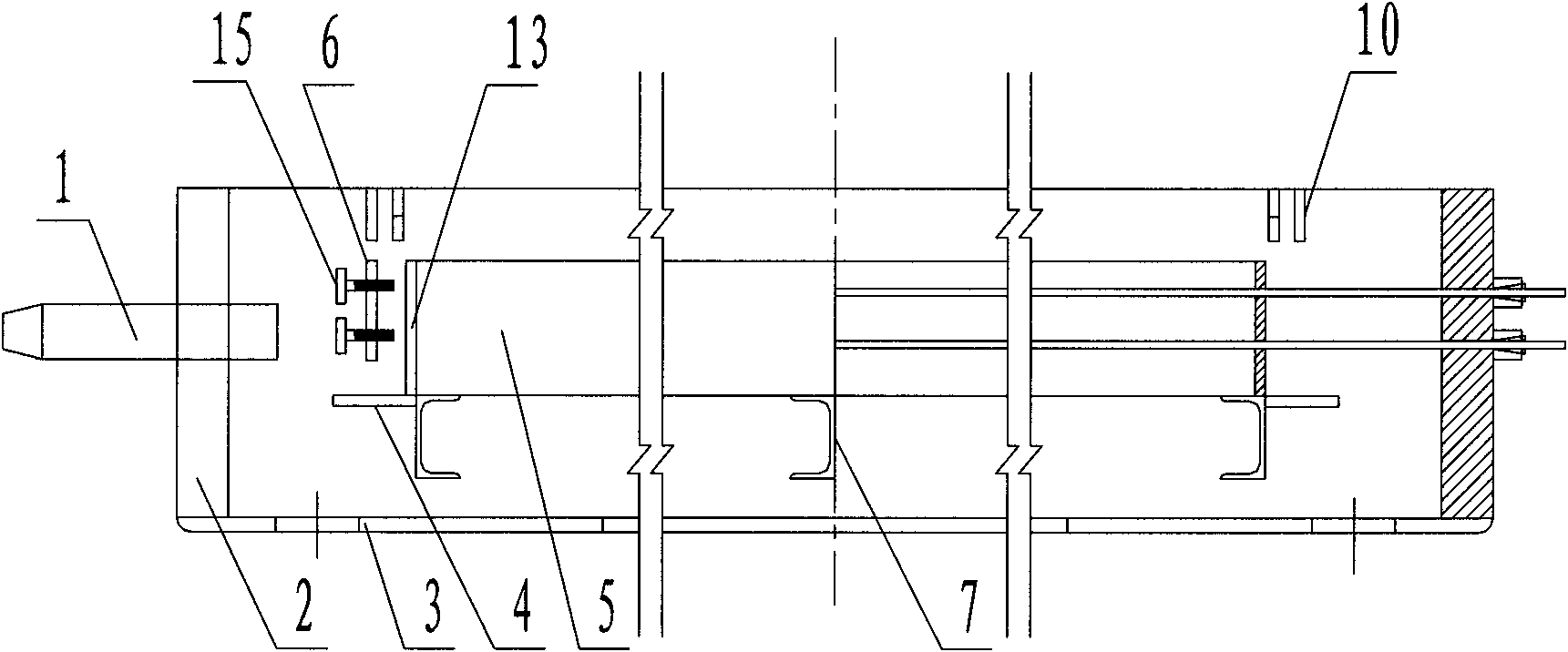

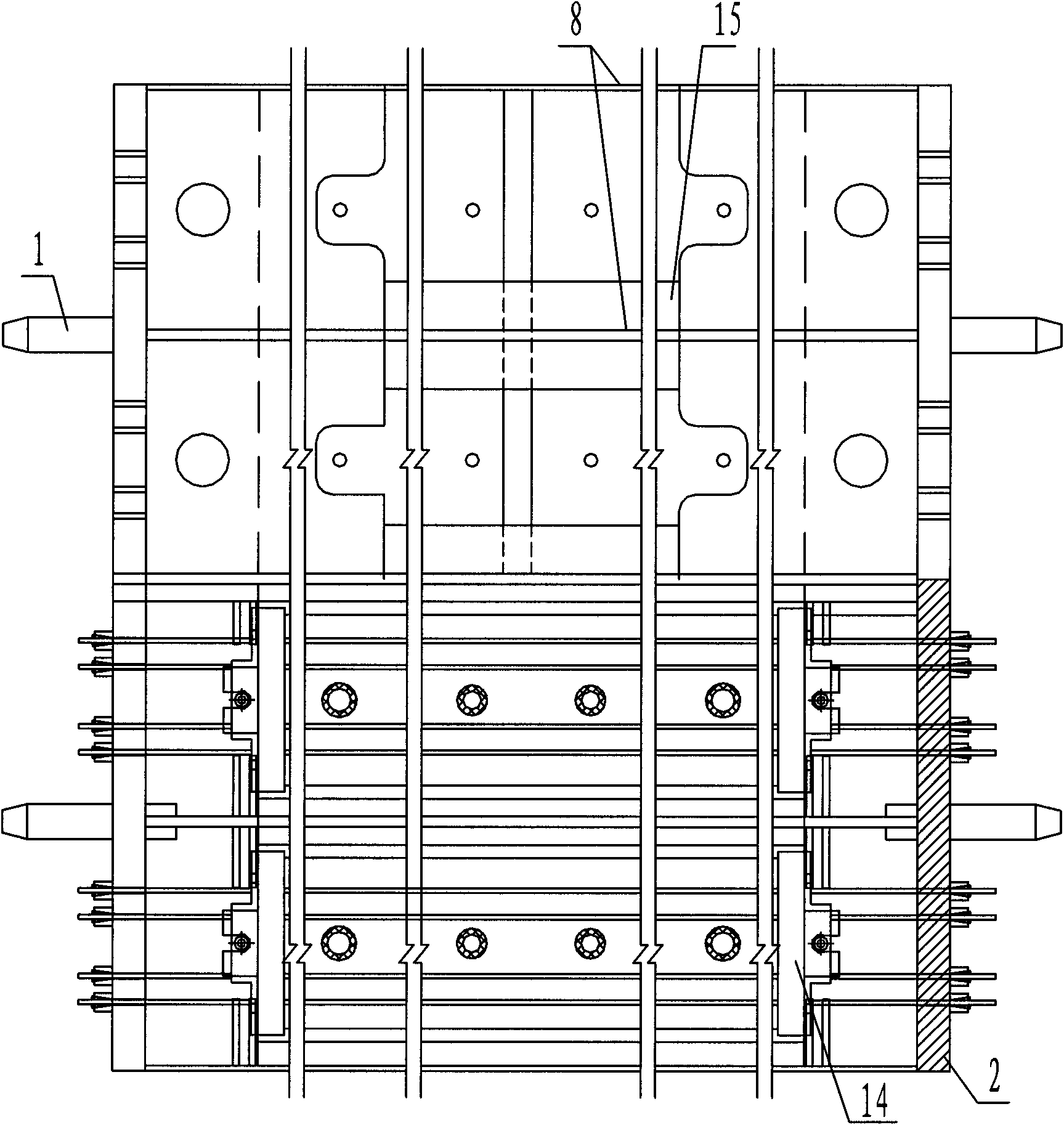

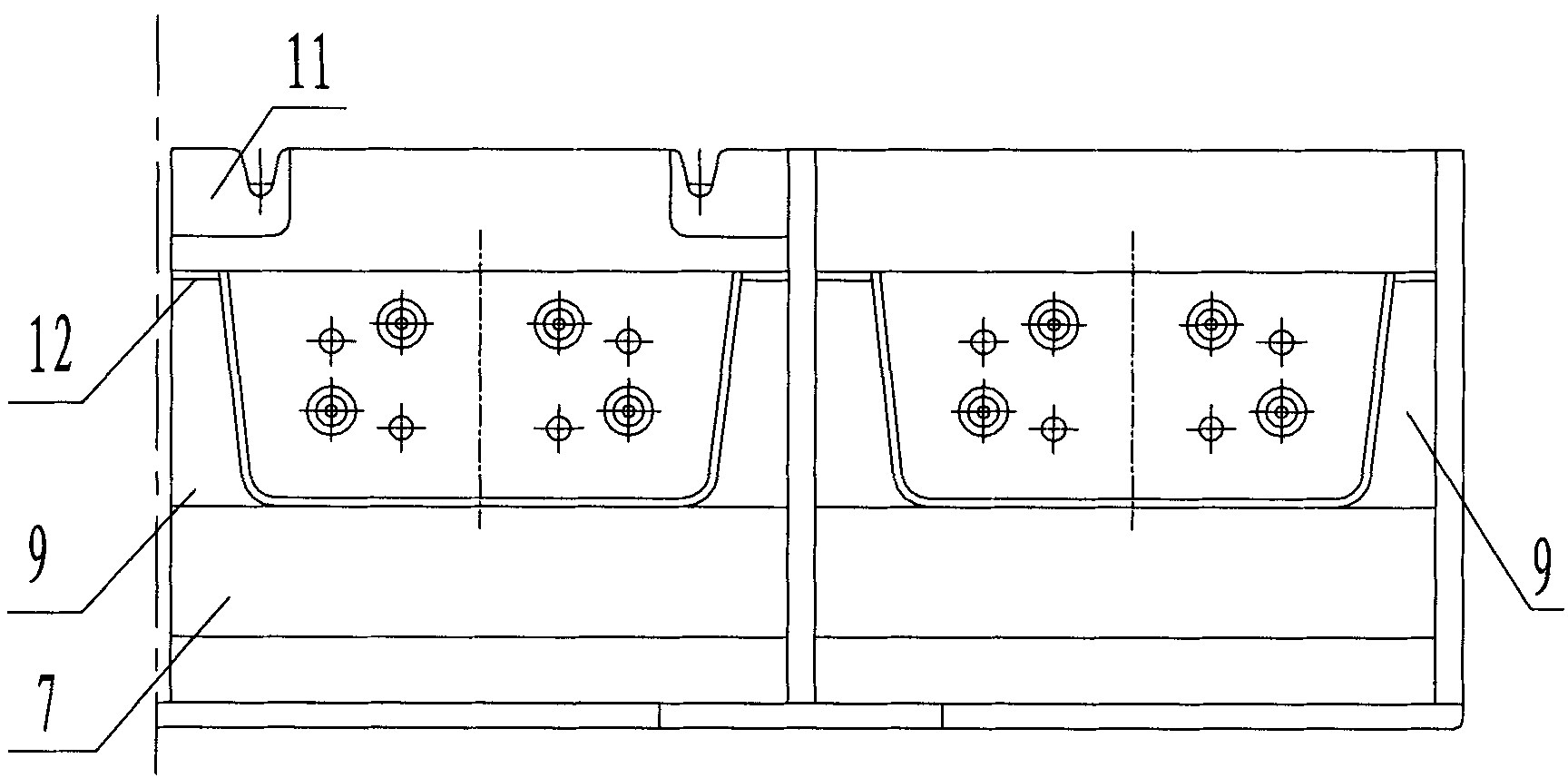

[0031] see Figure 1 to Figure 3 As shown, the ballastless transition sleeper steel mold body in the embodiment of the present invention includes: hanging shaft 1, end plate 2, bottom plate 3, supporting plate 4, steel mold shell 5, iron baffle plate fixing seat 6, connecting channel steel 7 , longitudinal plate 8, rib plate 9, steel bar positioning plate 10, steel bar support 11, cover plate 12, end baffle plate 13, truss fixing clip 14 and compression screw 15, wherein, the longitudinal plate 8 of the steel mold, the end plate 2 It forms a 1×4 steel mold frame structure with the bottom plate 3, and the periphery is wrapped by the bottom plate 3 and the end plate 2. The lower part of the steel mold shell 5 is connected to the longitudinal plate 8 through the connecting channel steel 7, and the upper part is connected to the longitudinal plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile load | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com