A method for determining the content of niobium, silicon and phosphorus in ferro-niobium manganese

A technology of phosphorus content, niobium and manganese, which is applied in the field of determination of niobium, phosphorus content and silicon in niobium manganese ferromanganese, which can solve the problems of silicon element volatilization loss, poor precision, low spectral intensity of phosphorus element, etc., to improve accuracy and precision Accuracy, high precision, avoid the effect of separation operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] 1) acid-soluble manganese: Weigh two samples in parallel, quality of 0.2002g / 0.2001g, respectively, were placed in a 250 ml plastic beaker Wang, aqua regia was added 20mL, 5 mL of dilute sulfuric acid (1 + 4), dissolved by heating, to take after fuming sulfuric acid, heating was continued to maintain the micro smoke ≥1min. 10 drops of nitric acid was added dropwise damage carbide, remove cooling, a small amount of deionized water was added when the smoke cup wall;

[0065] 2) solution of HF niobium and silicon: test solution to be cooled to room temperature, was added 5mL of hydrofluoric acid, the beaker was shaken to dissolve the sample completely, the plastic 50mL volumetric flask, add 2mL Nickel standard solution (100μg / mL);

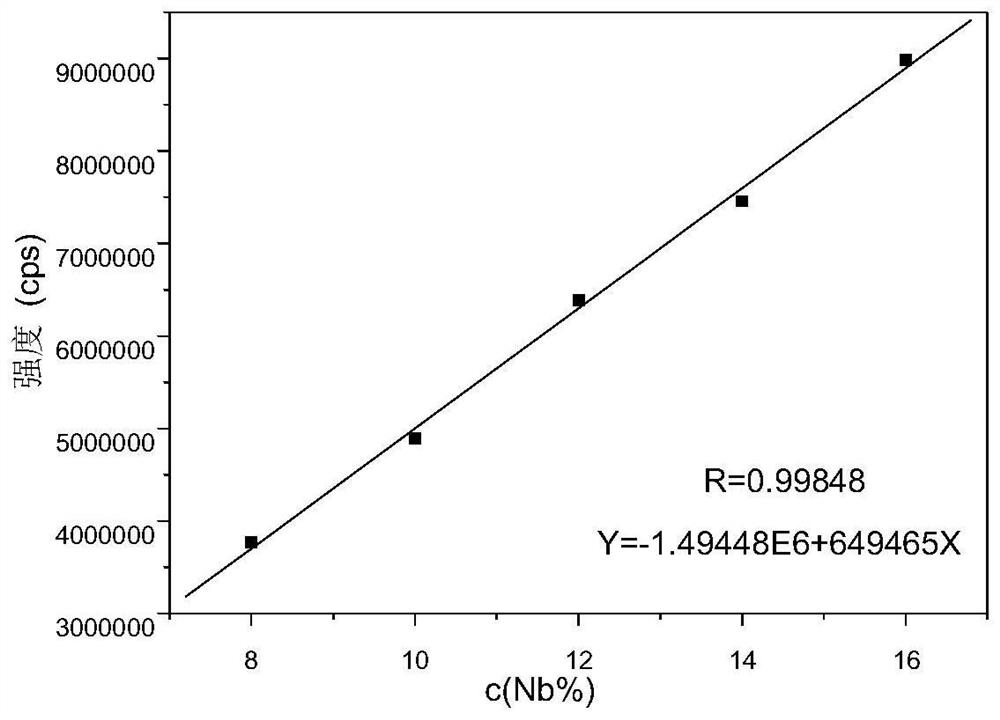

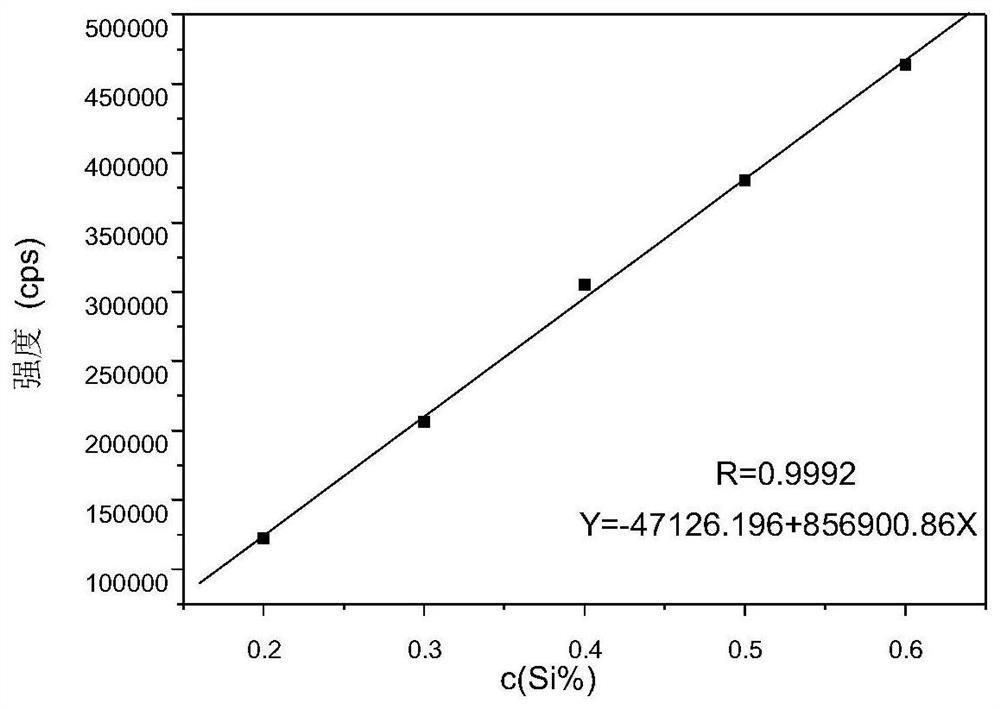

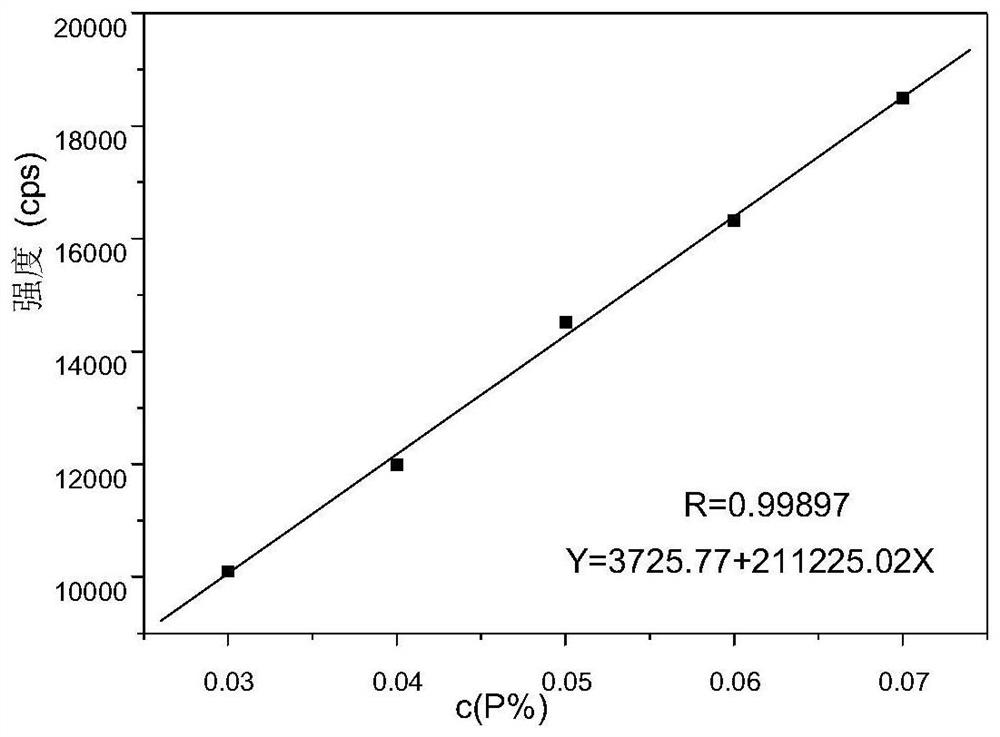

[0066] 3) Draw standard curve:

[0067] Were prepared niobium (10mg / mL), silicon (400μg / mL), phosphorus (10μg / mL) standard solution.

[0068] Formulated in specification method for the base liquor, the prepared substrate the mother liquor...

Embodiment 2

[0073] 1) acid-soluble manganese: Weigh two samples in parallel, quality of 0.2000g / 0.2002g, respectively, were placed in a 250 ml plastic beaker Wang, aqua regia was added 20mL, 5 mL of dilute sulfuric acid (1 + 4), dissolved by heating, to take after fuming sulfuric acid, heating was continued to maintain the micro smoke ≥1min. 10 drops of nitric acid was added dropwise damage carbide, remove cooling, a small amount of deionized water was added during the cup wall smoke.

[0074] 2) solution of HF niobium and silicon: test solution to be cooled to room temperature, was added 5mL of hydrofluoric acid, the beaker was shaken to dissolve the sample completely, the plastic 50mL volumetric flask, add 2mL Nickel standard solution (100μg / mL).

[0075] 3) Draw standard curve:

[0076] Were prepared niobium (10mg / mL), silicon (400μg / mL), phosphorus (10μg / mL) standard solution.

[0077] Formulated in specification method for the base liquor, the prepared substrate liquor, the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com