Corrosion-preventing and shock-absorbing vehicle chassis guard board with coating

An automobile chassis and coating technology, which is applied in the direction of layered products, vehicle parts, rubber layered products, etc., can solve the general problems of shock absorption and noise resistance, and achieve high puncture resistance, damage reduction, and good anti-corrosion performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Whether it is the engine chassis guard or the whole vehicle chassis guard, the section is the same as figure 1 As shown, the outer surface of the automobile chassis guard plate 2 is sprayed with a liquid rubber spray coating 1, and the thickness of the liquid rubber spray coating 1 is 1-3 mm. The car chassis guard plate is a resin base plate, a steel plate or a titanium alloy base plate.

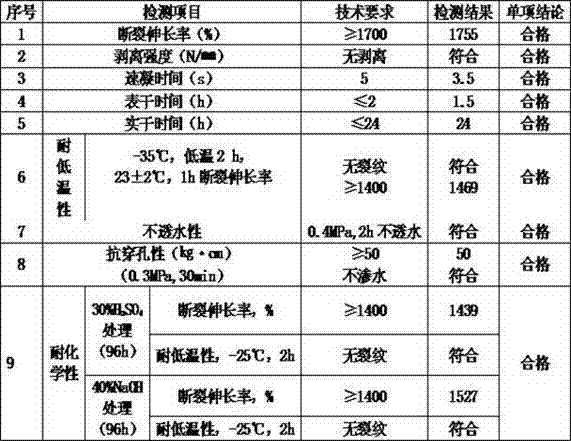

[0014] Detect through test, the performance of the present invention can reach the following table:

[0015]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com