Hydraulic brake sealing device

A sealing device and hydraulic technology, applied in bicycle accessories, bicycle brakes, etc., can solve the problems of affecting driving safety, easy accelerated aging of oil seals, oil leakage, etc., and achieve the effect of reliable braking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

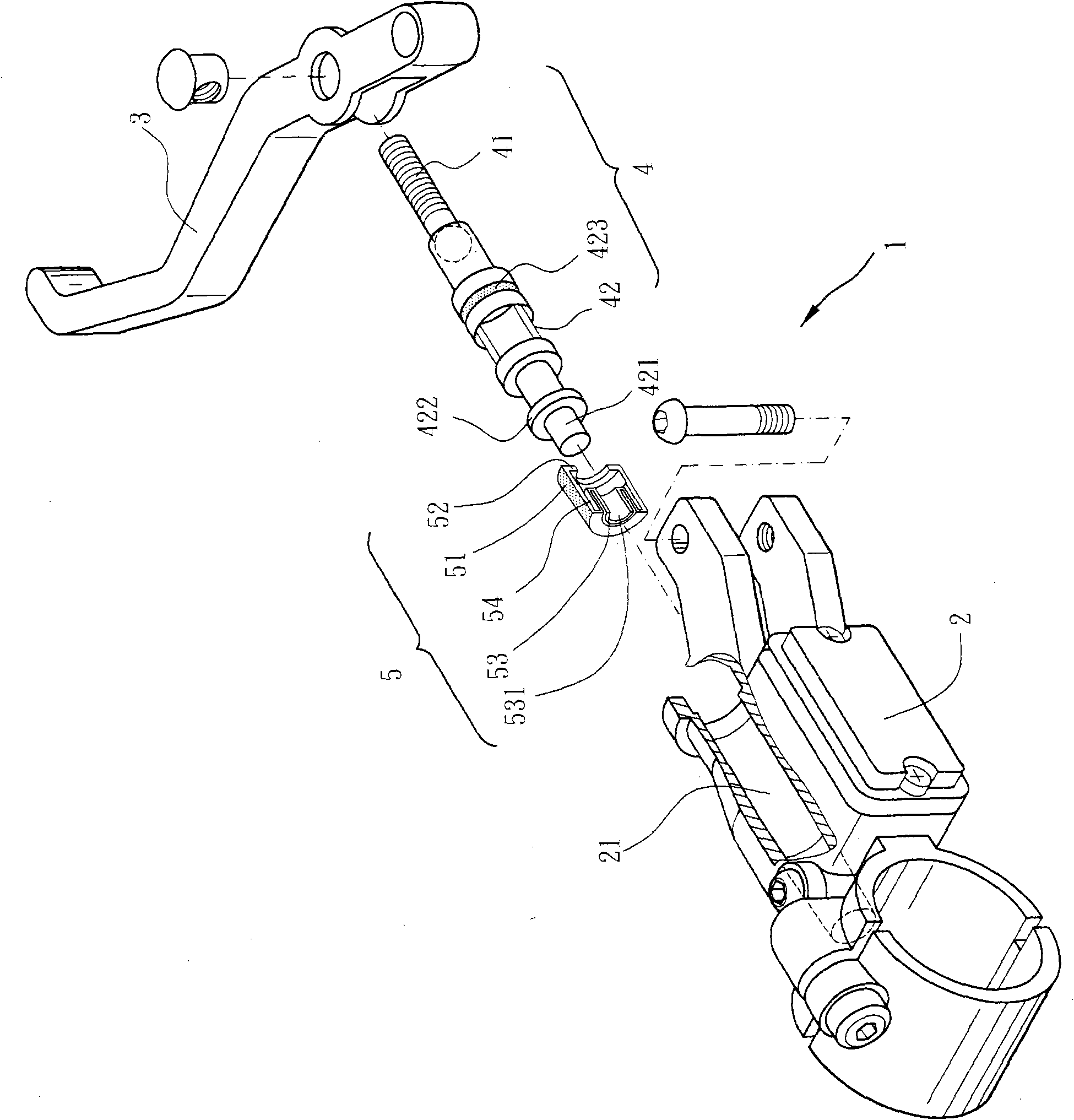

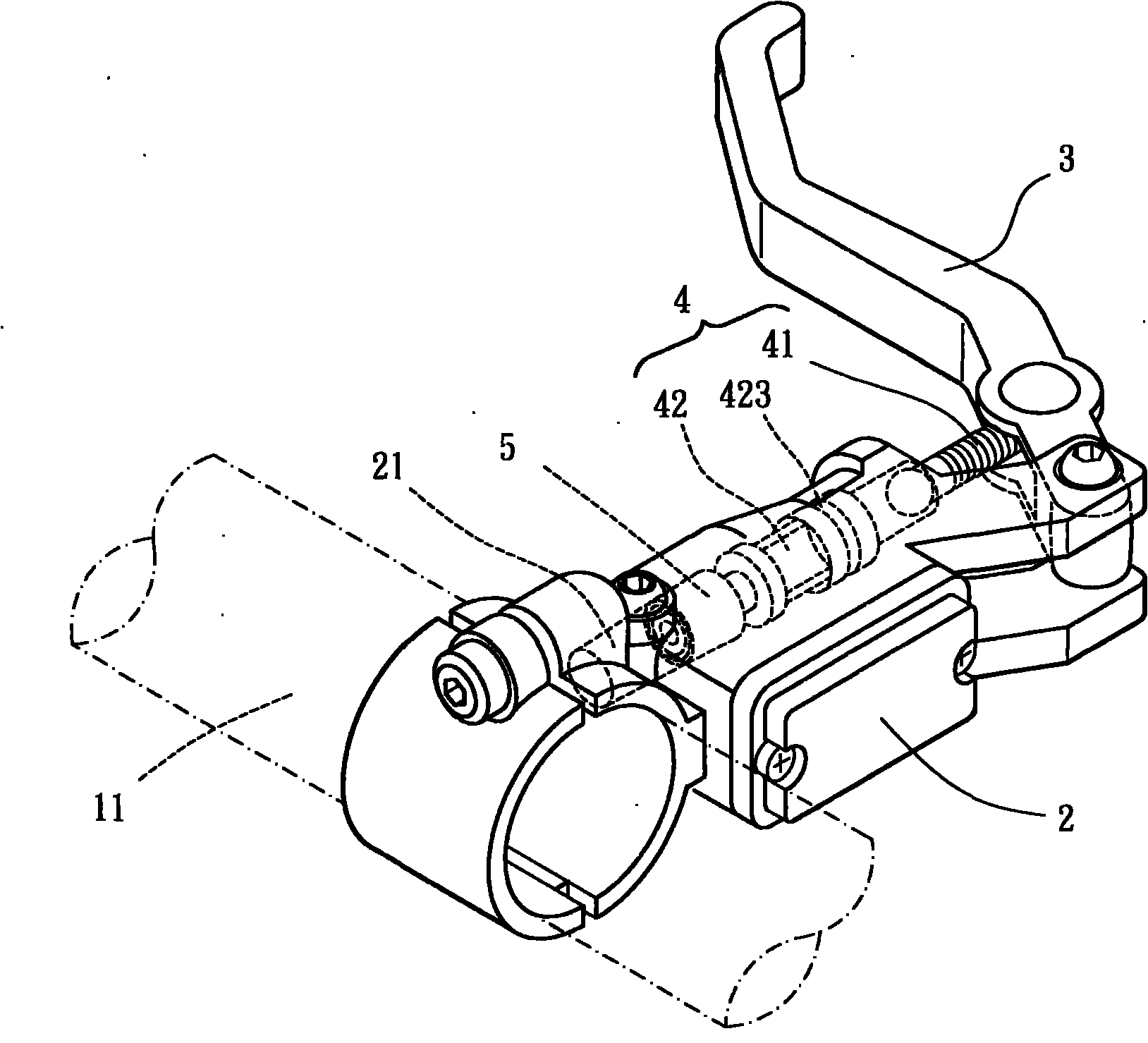

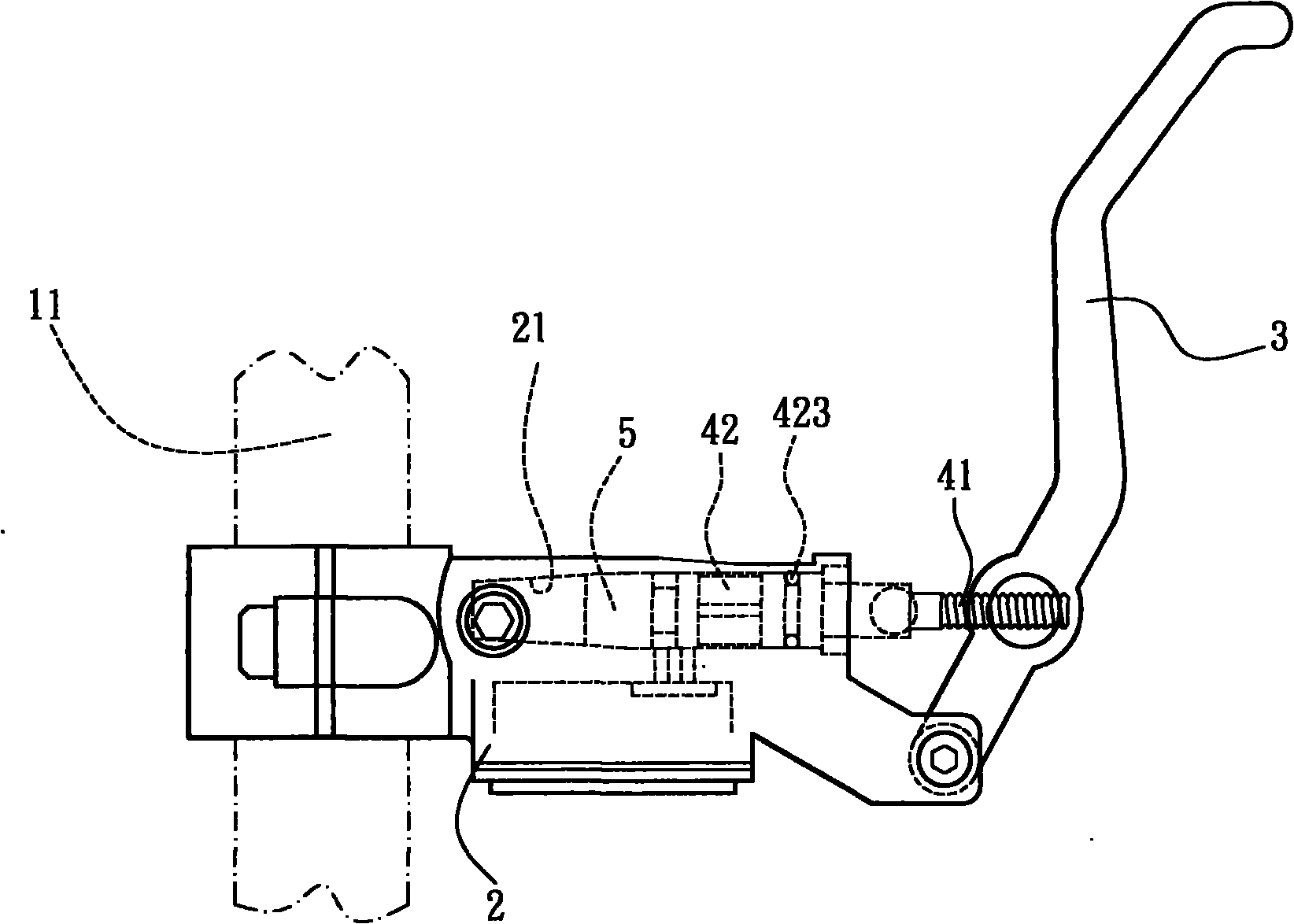

[0034] Please refer to figure 1 and figure 2 As shown, the hydraulic brake sealing device 1 of the present invention is shown in the figure, which includes an oil chamber seat 2 installed on the handlebar 11, a brake handle 3 pivotally arranged at one end of the oil chamber seat 2, and a brake handle 3 with one end assembled to the brake handle 3. The piston group 4 and a set of elastic parts 5 arranged at the other end of the piston group 4, wherein:

[0035] The oil chamber seat 2 is provided with a hollow oil chamber 21, and an oil supply pipe assembly interface 211 is provided near the bottom side edge of the oil chamber 21, and the oil chamber 21 is tapered toward the bottom interface of the oil chamber 21. Tapered groove pattern;

[0036] The brake handle 3 is pivotally connected to the oil chamber seat 2 at one end and is located outside the opening of the oil chamber 21;

[0037] The piston group 4 includes a driving rod 41 with one end connected to the brake handl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com