Low emissivity glass containing silver

A low-emissivity glass and a manufacturing method technology, applied in the field of special glass, can solve the problems of appearance color showing interference color, reducing visible light transmittance, affecting the use of glass, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

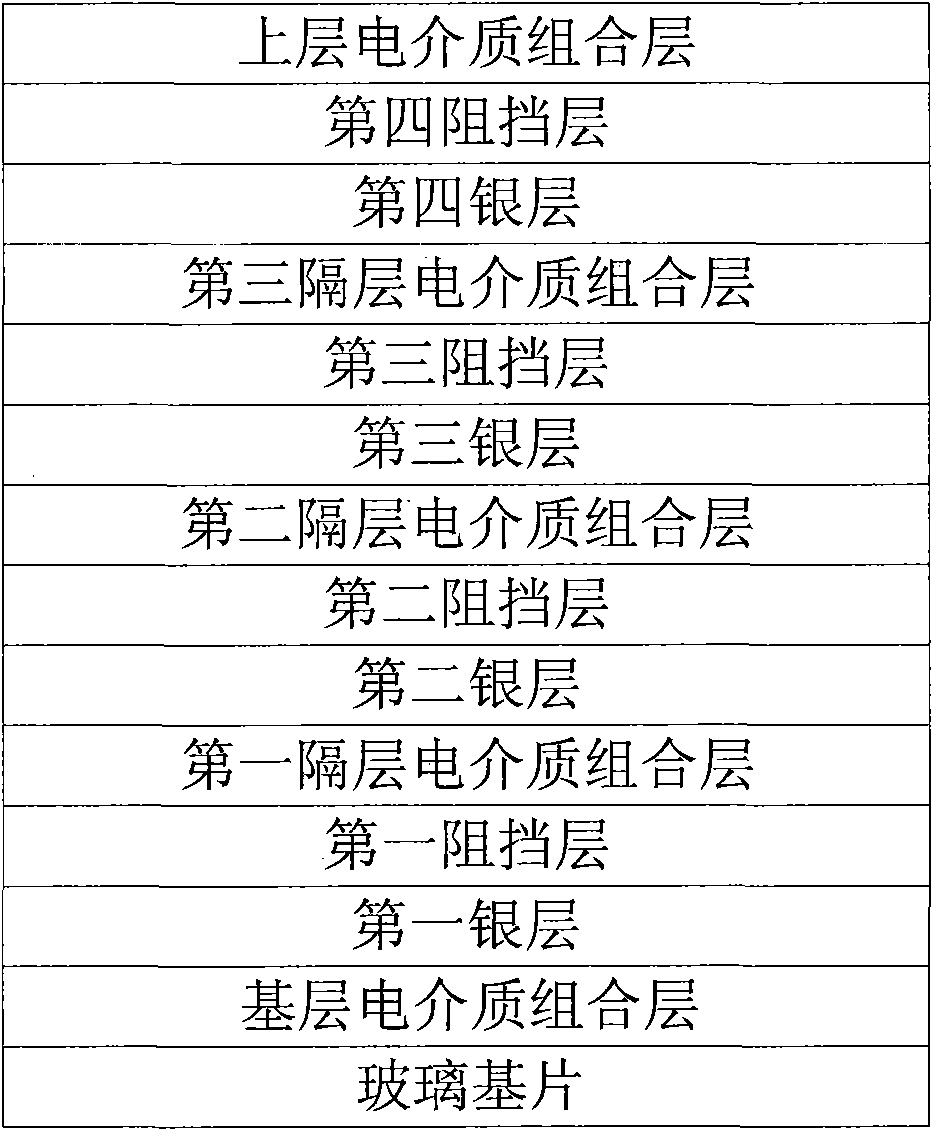

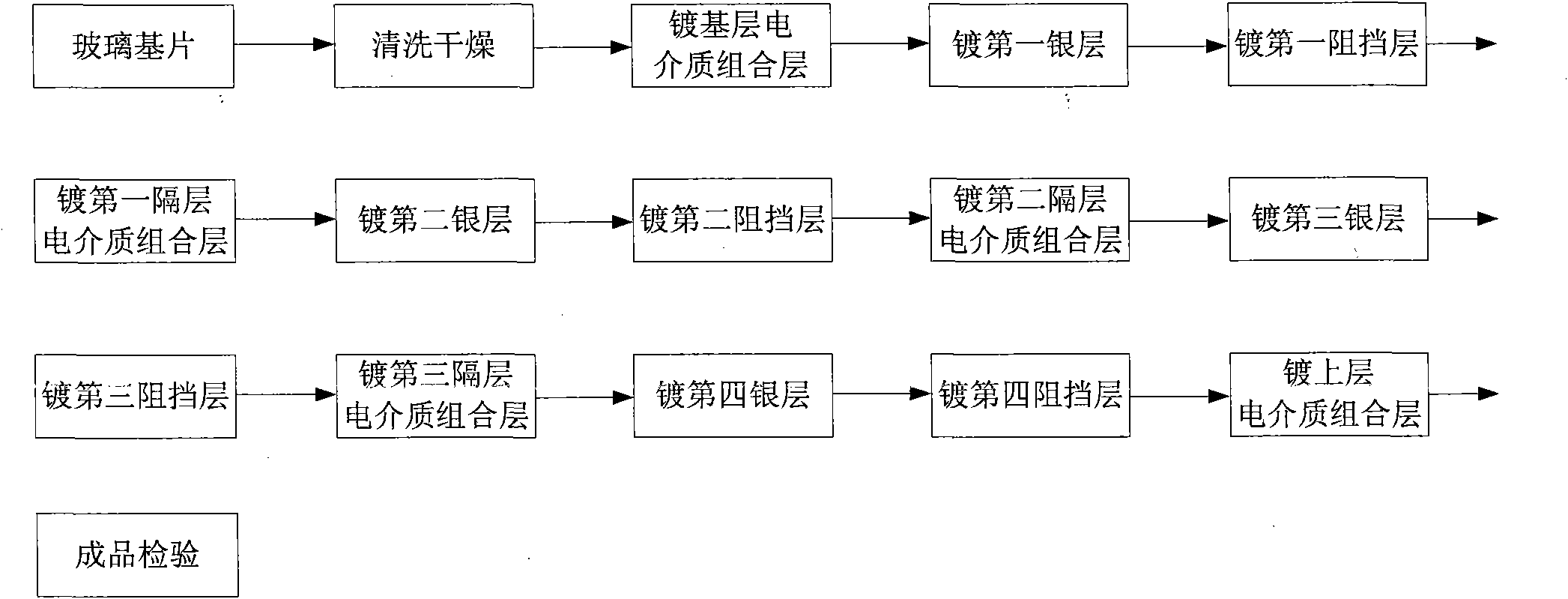

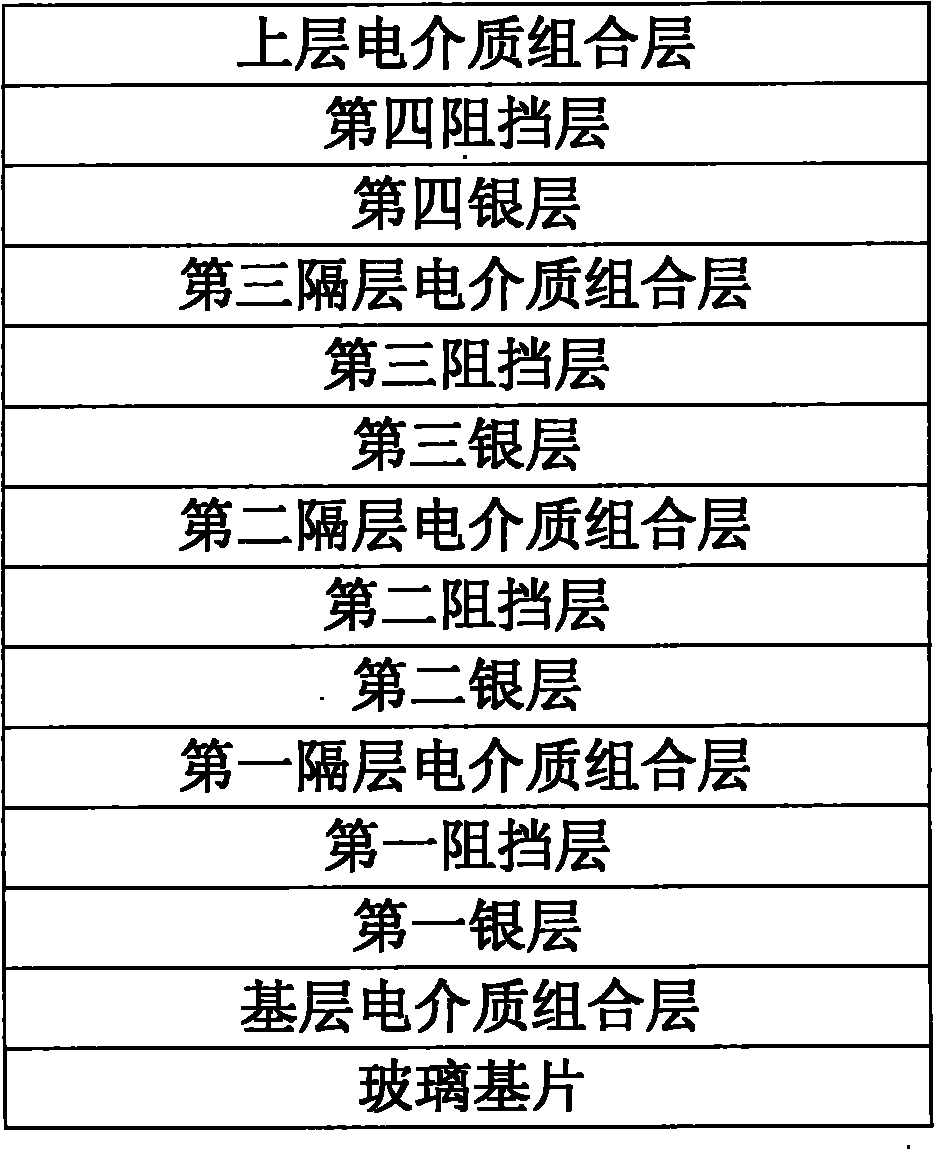

[0069] The film structure of the silver-containing low-emissivity glass embodiment 1 is as follows: glass, ZnSnO x , Ag, NiCrO x , ZnSnO x , Ag, NiCrO x , ZnSnO x , Ag, NiCrO x , ZnSnO x , Ag, NiCrO x , ZnSnO x 、Si 3 N 4 .

[0070] In this embodiment, the base dielectric combination layer is ZnSnO x layer with a thickness of 27 nm.

[0071] In this embodiment, the thickness of the first silver layer is 8nm.

[0072] In this embodiment, the first barrier layer is NiCrO x layer with a thickness of 0.3 nm.

[0073] In this embodiment, the first interlayer dielectric combination layer is ZnSnO x layer with a thickness of 69 nm.

[0074] In this embodiment, the thickness of the second silver layer is 12nm.

[0075] In this embodiment, the second barrier layer is NiCrO x layer with a thickness of 0.3 nm.

[0076] In this embodiment, the second interlayer dielectric combination layer is ZnSnO x layer with a thickness of 71 nm.

[0077] In this embodiment, the thic...

Embodiment 2

[0094] The film structure of another specific embodiment of the silver-containing low-emissivity glass is as follows: glass, Si 3 N 4 , Ag, NiCr, Si 3 N 4 , Ag, NiCr, Si 3 N 4 , Ag, NiCr, Si 3 N 4 , Ag, NiCr, Si 3 N 4 、TiO 2 .

[0095] In this embodiment, the base dielectric combination layer is Si 3 N 4 layer with a thickness of 25 nm.

[0096] In this embodiment, the thickness of the first silver layer is 7.6 nm.

[0097] In this embodiment, the first barrier layer is a NiCr layer with a thickness of 0.3 nm.

[0098] In this embodiment, the first interlayer dielectric combination layer is Si 3 N 4 layer with a thickness of 67 nm.

[0099] In this embodiment, the thickness of the second silver layer is 10.8nm.

[0100] In this embodiment, the second barrier layer is a NiCr layer with a thickness of 0.3 nm.

[0101] In this embodiment, the second interlayer dielectric combination layer is Si 3 N 4 layer with a thickness of 69 nm.

[0102] In this embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com