Oxygen-supplementation-type fume gas circulation combustion device

A flue gas circulation and combustion device technology, applied in combustion methods, combustion equipment, solid fuel combustion, etc., can solve problems such as wasting energy and polluting the environment, and achieve increased purity, less flue gas emissions, and less nitrogen oxides. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

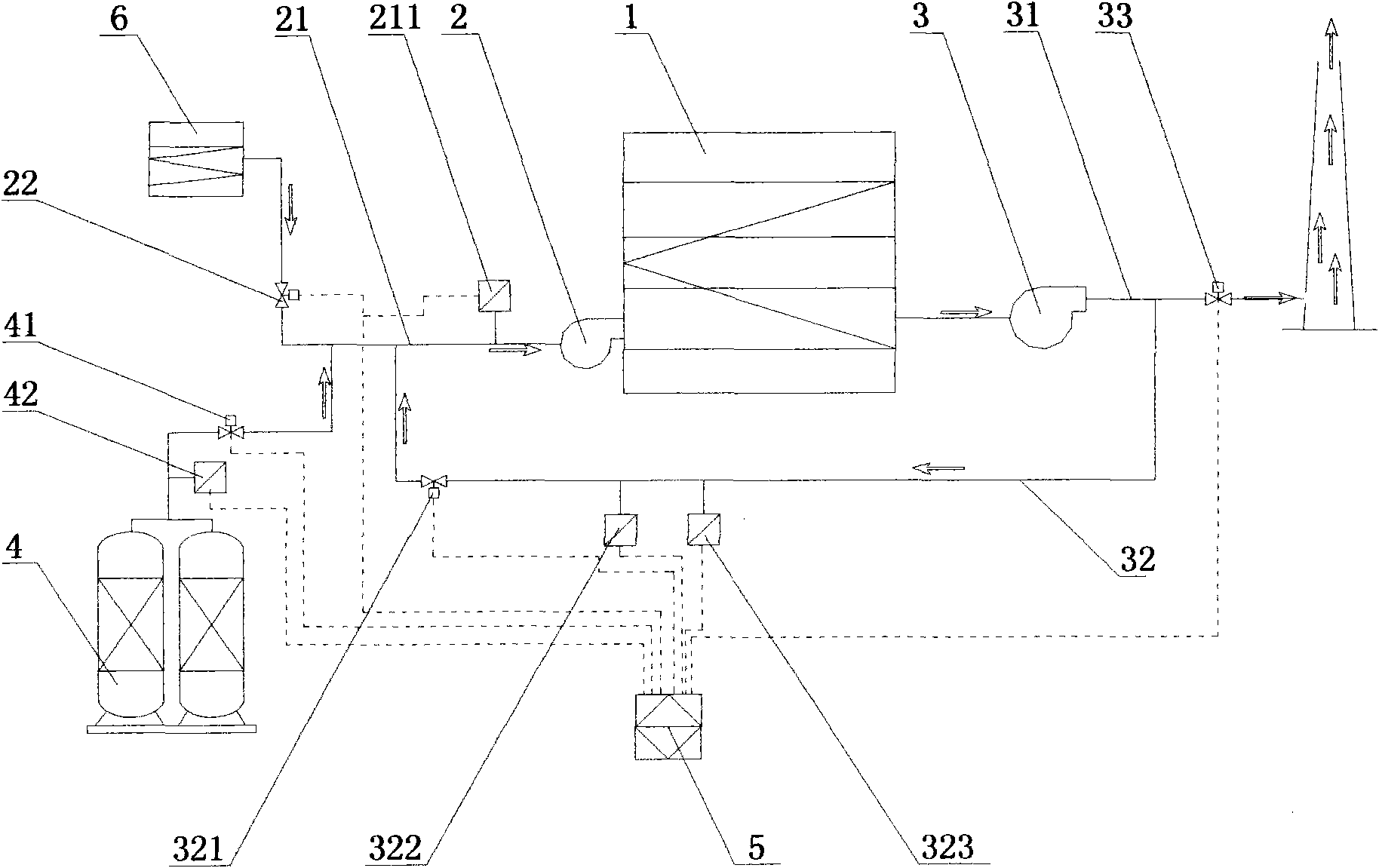

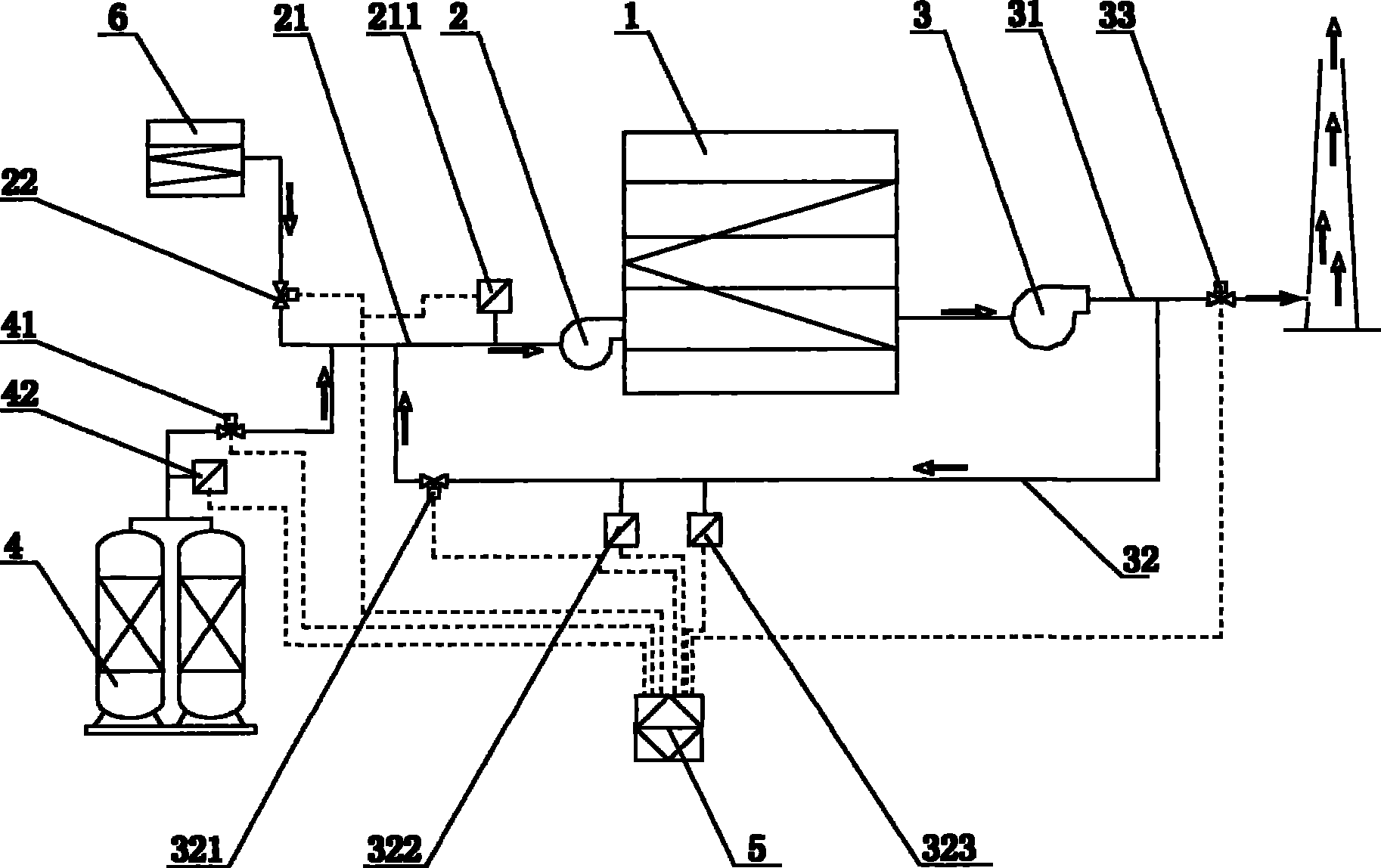

[0013] Such as figure 1 As shown, the oxygen-supplementing flue gas circulation combustion device of this embodiment includes a combustion chamber 1 and a blower 2 and a flue gas induced draft fan 3 that are respectively connected to the combustion chamber 1 through pipelines. The air damper 22 is connected, the smoke outlet of the smoke induced draft fan 3 is connected with the smoke exhaust damper 32 through the smoke exhaust pipe 31, the smoke exhaust pipe 31 is connected with the air inlet pipe 21 through the smoke circulation pipe 32, and the air inlet pipe 21 is connected with the output end of the oxygen supply device 4 .

[0014] In this embodiment, the flue gas circulation pipe 32 is provided with a flue gas circulation volume regulating damper 321, the output end of the oxygen supply device 4 is provided with an oxygen flow regulating valve 41, the oxygen supply device 4 is a vacuum oxygen generator, and the fresh air wind The inlet of the valve 22 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com