Graphitized short fibers and composition thereof

A technology of graphitization and short fibers, applied in fiber processing, fiber chemical characteristics, textiles and papermaking, etc., can solve problems such as difficult curing reactions, and achieve the effects of excellent mechanical strength, high thermal conductivity and softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

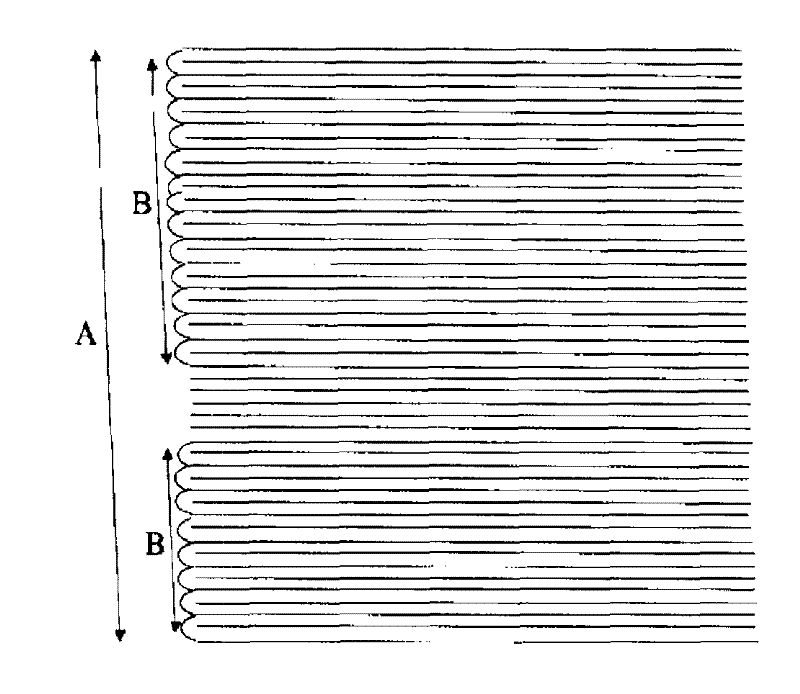

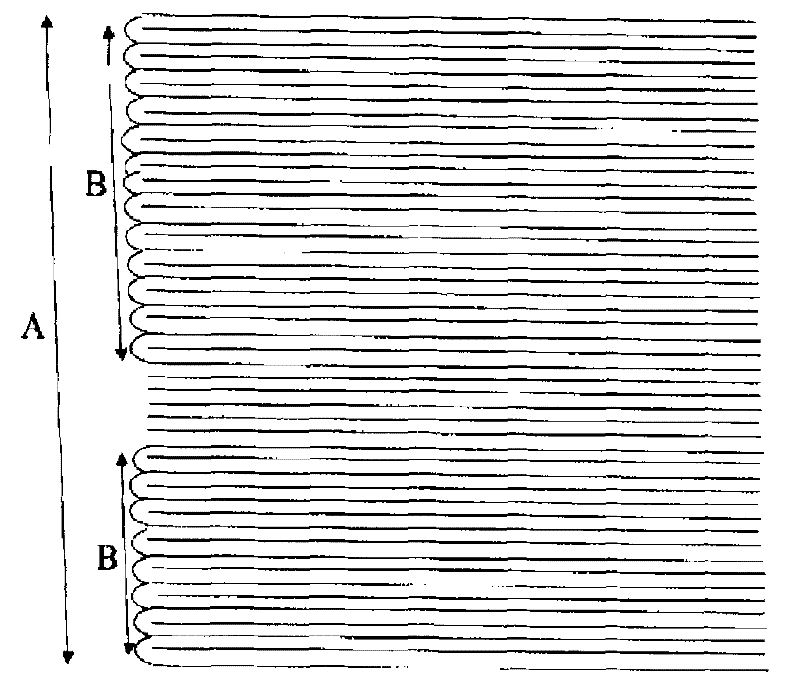

Image

Examples

Embodiment 1

[0088] The main raw material is mesophase pitch containing condensed polycyclic hydrocarbon compounds. The optical anisotropy ratio is 100%, and the softening point is 286°C. Using a cap with a hole diameter of 0.2 mmφ, heated air was sprayed from the slit at a speed of 9700 m / min to draw molten pitch to produce a pitch-based carbon fiber precursor with an average diameter of 15.5 μm. The spinning temperature at this time was 341° C., and the melt viscosity was 9.5 Pa·S (95 poise). The spun pitch-based carbon fiber precursor is collected on a belt to form a net, and then cross-laid to form a unit area weight of 380g / m 2 A pitch-based carbon fiber precursor network comprising a pitch-based carbon fiber precursor.

[0089] The pitch-based carbon fiber precursor web was heated from 170° C. to 320° C. at an average temperature increase rate of 7° C. / min in air to infusible it. At this time, the amount of oxygen attached to the pitch-based infusible fiber web was 6.6 wt%. Furth...

Embodiment 2

[0094] 15 parts by weight of the pitch-based graphitized short fibers (short fibers B) obtained in Example 1 and polyether-modified polydimethylsilane were mixed using an autorotation-revolving mixer (trade name "Awatori Rentaro ARV310" manufactured by Sinki Corporation). 100 parts by weight of oxane (trade name "BYK-302" manufactured by Big Chemical Co., Ltd.) was mixed for 6 minutes to obtain a rubber composition. After treating this at 80° C., it was cured over 70 minutes. The curing time of BYK-302 at 80°C is 70 minutes. That is, the curing time of the thermally conductive rubber composition is 1.0 times the curing time of the rubber component.

[0095] Next, the obtained rubber composition was press-processed by a vacuum press machine (Kitagawa Seiki Co., Ltd.) to obtain a flat composite molded body with a thickness of 0.5 mm, which was cured at 130° C. for 2 hours to produce a sheet-shaped thermally conductive material. Shaped body. The thermal conductivity of the she...

Embodiment 3

[0101] The main raw material is mesophase pitch containing condensed polycyclic hydrocarbon compounds. The optical anisotropy ratio is 100%, and the softening point is 283°C. Using a cap with a hole diameter of 0.2 mmφ, heated air was sprayed from the slit at a speed of 8500 m / min to draw molten pitch to produce a pitch-based carbon fiber precursor with an average diameter of 14.5 μm. The spinning temperature at this time was 335° C., and the melt viscosity was 10.5 Pa·S (105 poise). The spun pitch-based carbon fiber precursor is collected on a belt to form a net, and then cross-laid to form a weight per unit area of 400g / m 2 A pitch-based carbon fiber precursor network comprising a pitch-based carbon fiber precursor.

[0102] The pitch-based carbon fiber precursor web was heated from 170° C. to 320° C. at an average temperature increase rate of 6° C. / min in air to prevent melting. The amount of oxygen attached to the pitch-based infusible fiber web at this time was 6.5 w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com