Sodium gualenate aqueous solution

A technology of sodium azulene sulfonate and aqueous solution, which is applied in the fields of anhydride/acid/halide active ingredients, drug delivery, cosmetic preparations, etc. It can solve the problems of low solubility, difficulty in manufacturers, and lack of raw materials, etc., and achieve the effect of simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1 (taking the preparation of 100kg as an example)

[0017] Sodium azulene sulfonate 0.45kg

[0018] Sterile purified water 99.5kg

[0019] Total: 100kg

[0020] In a 100,000-level purification workshop, weigh 0.45 kg of sodium azulene sulfonate, add 5 kg of purified water, heat to boiling, then add 94.5 kg of purified water at room temperature after heat sterilization, and stir evenly to obtain a semi-finished product of sodium azulene sulfonate aqueous solution. After the three indicators of sodium azulene sulfonate content, pH value, and total number of microorganisms pass the inspection, it can be packaged in a sterilized and dry-controlled packaging barrel to obtain a finished product of sodium azulene sulfonate aqueous solution (SGS-100).

Embodiment 2

[0021] Embodiment 2 (taking the preparation of 100kg as an example)

[0022] Sodium azulene sulfonate 0.55kg

[0023] Sterile purified water 99.45kg

[0024] Total: 100kg

[0025] In a 100,000-level purification workshop, weigh 0.55 kg of sodium azulene sulfonate, add 5 kg of purified water, heat to boiling, then add 94.45 kg of purified water at room temperature after heat sterilization, and stir evenly to obtain a semi-finished product of sodium azulene sulfonate aqueous solution. After the three indicators of sodium azulene sulfonate content, pH value, and total number of microorganisms pass the inspection, it can be packaged in a sterilized and dry-controlled packaging barrel to obtain a finished product of sodium azulene sulfonate aqueous solution (SGS-100).

Embodiment 3

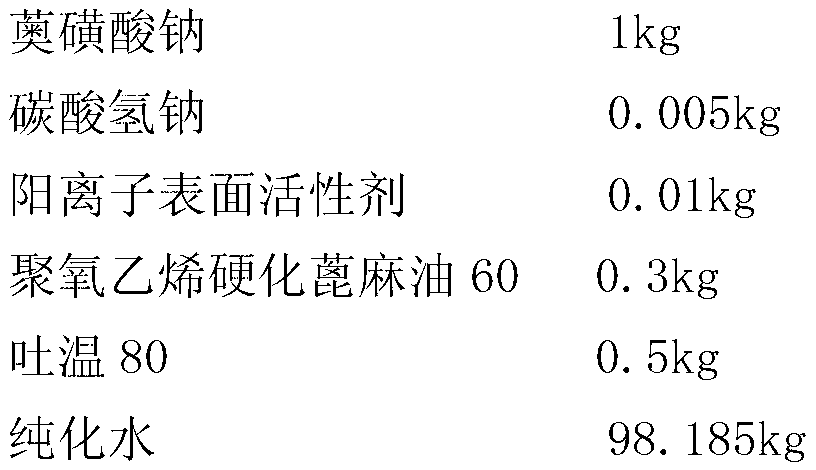

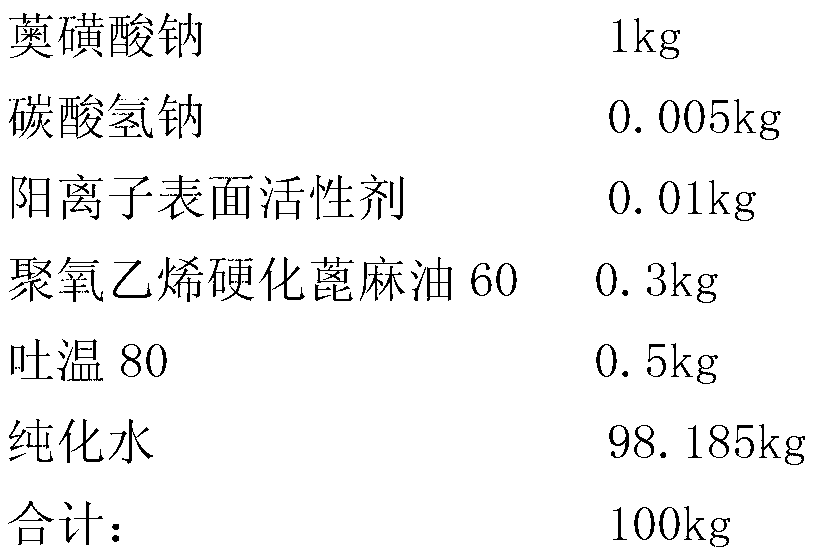

[0026] Embodiment 3 (taking the preparation of 100kg as an example)

[0027]

[0028] In the purification workshop, utensils and equipment are sterilized with 75% ethanol before use. First weigh 60,0.3kg of polyoxyethylene hardened castor oil, dissolve it into 98.185kg of purified water sterilized by ultraviolet rays, stir evenly, then add 800.5kg of Tween, stir well, then add 0.005kg of sodium bicarbonate, add cation Surfactant 0.1kg, finally add sodium azulene sulfonate 1kg, stir for 30 minutes to dissolve completely, obtain the semi-finished product of aqueous solution of sodium azulene sulfonate, after the three indicators of sodium azulene sulfonate content, pH value, and total number of microorganisms are qualified, namely It can be packaged in a sterilized and dry-controlled packaging barrel to obtain the finished product of sodium azulene sulfonate aqueous solution (SGS-100).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com