Continuous extraction device and continuous extraction method adopting same

An extraction device and extraction liquid technology, applied in the direction of extraction distillation, liquid solution solvent extraction, etc., can solve the problems of high production site requirements, low extraction efficiency, high extraction equipment height, etc., and achieve low production site requirements and low height Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

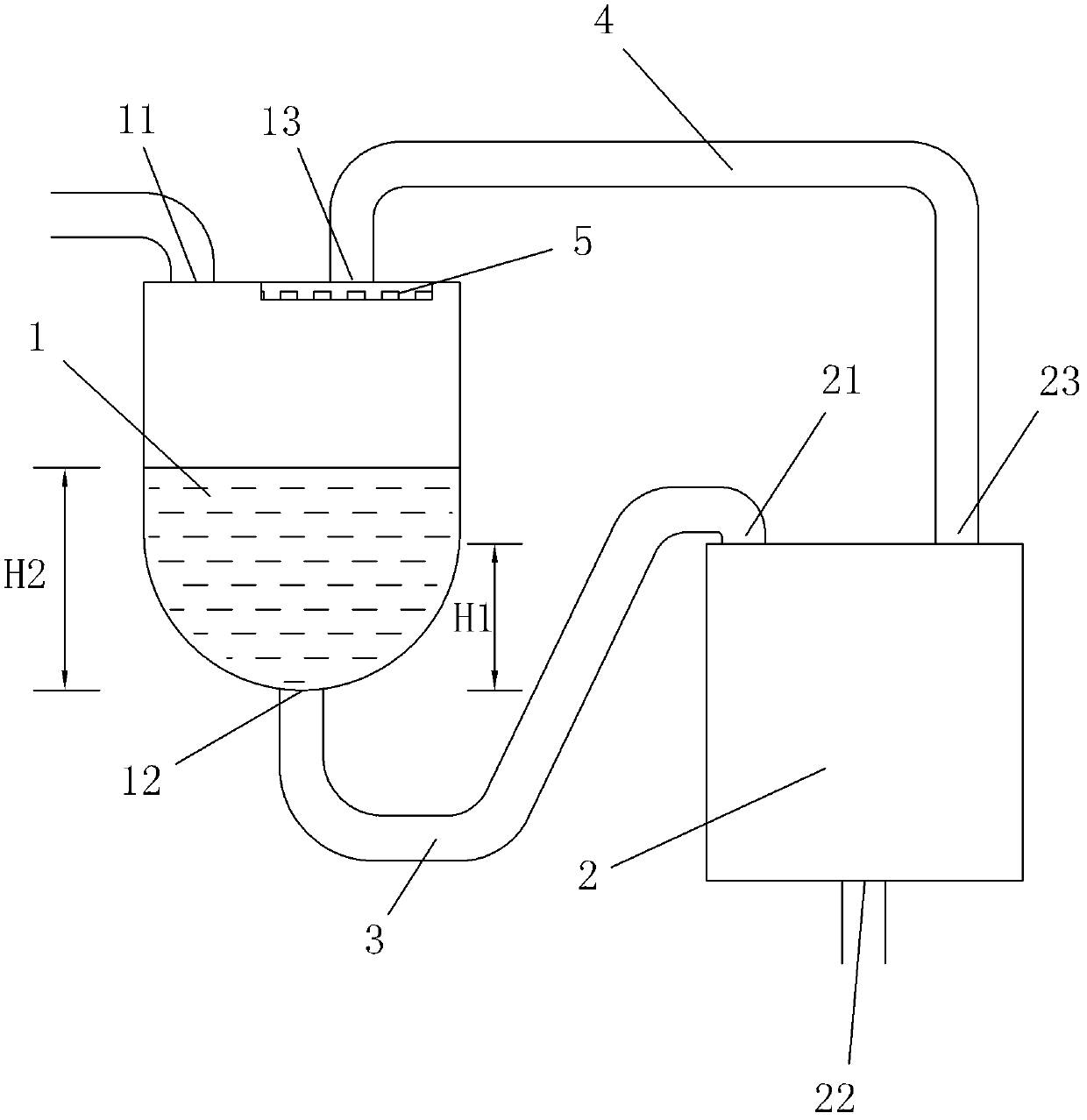

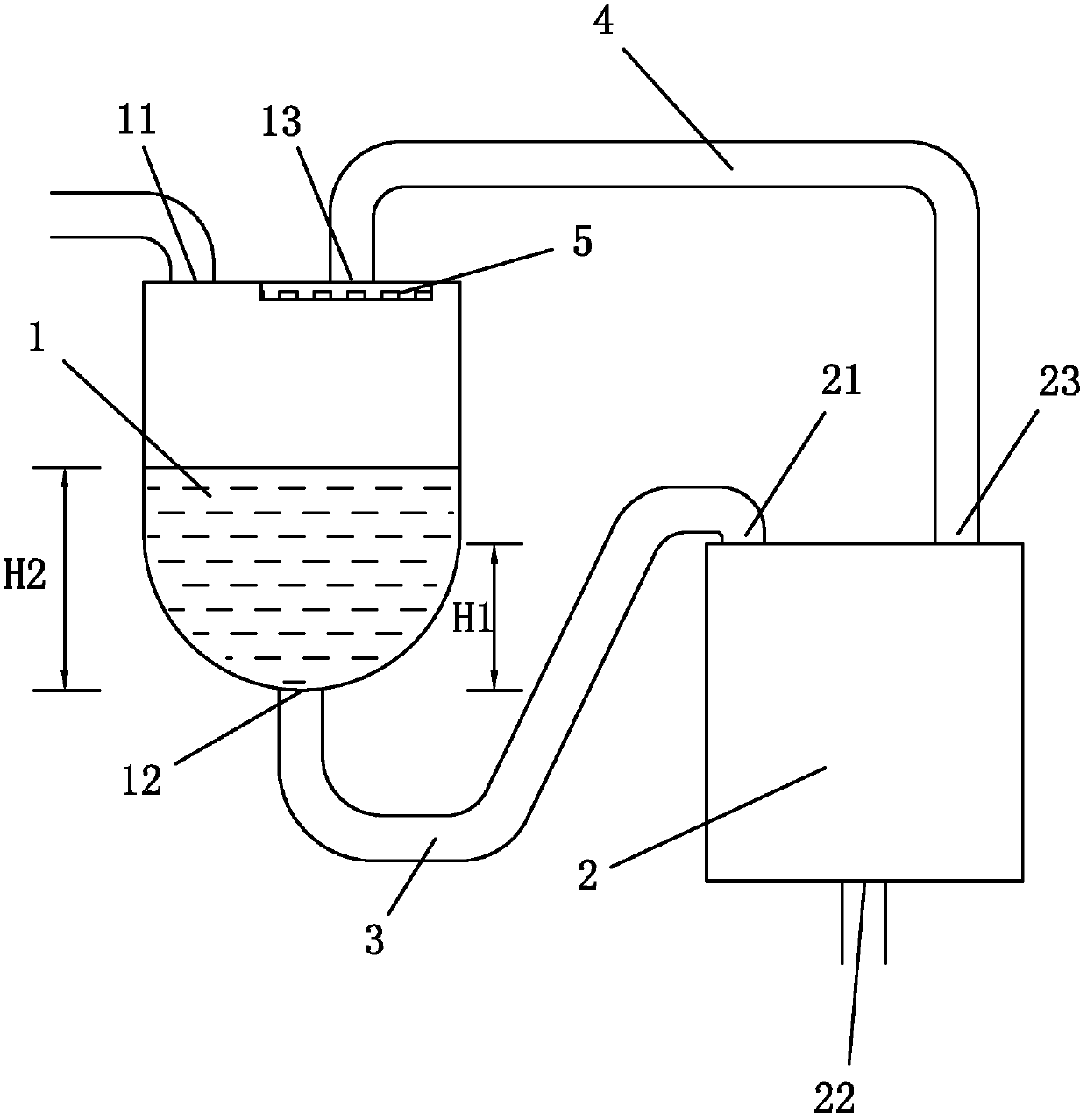

[0014] See figure 1 , The continuous extraction device of this embodiment includes an extraction kettle 1 and a distillation kettle 2.

[0015] The extraction kettle 1 is provided with a feed inlet 11 , an outlet 12 for an extract and an outlet 13 for an extractant return. The still 2 is provided with an inlet 21 for extracting liquid, an outlet 22 for solute and an outlet 23 for steaming the extraction agent.

[0016] The extraction liquid outlet 12 of the extraction kettle 1 is connected with the extraction liquid inlet 21 of the still 2 through the extraction liquid pipe 3 . The extraction agent steam outlet 23 of the still 2 is connected with the extraction agent return port 13 of the extraction kettle 1 through the extractant pipe 4 .

[0017] The ratio of the distance H2 between the extraction solution outlet 12 of the extraction kettle 1 and the liquid level in the extraction kettle 1 to the distance H1 between the extraction solution outlet 12 of the extraction kettl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com