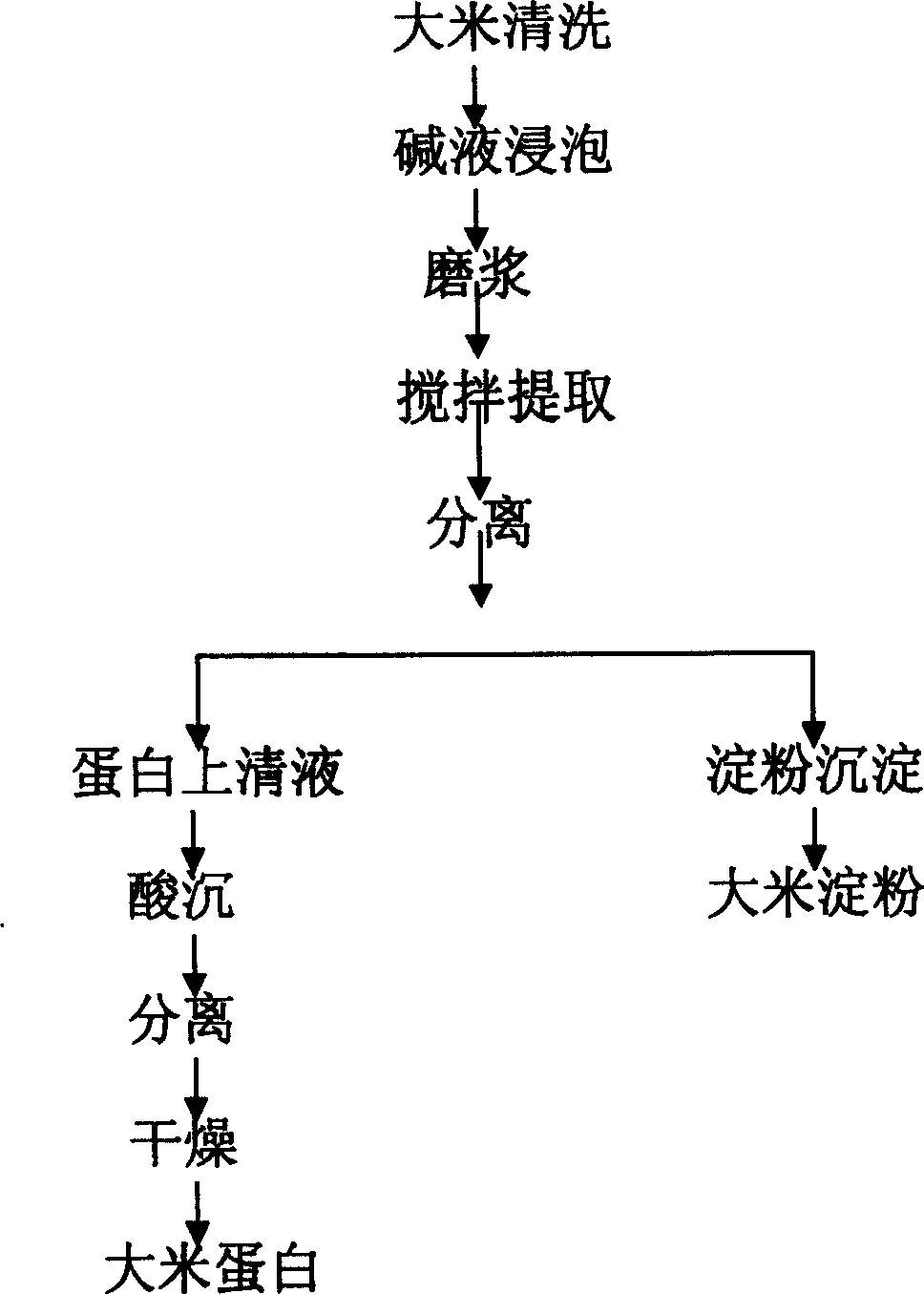

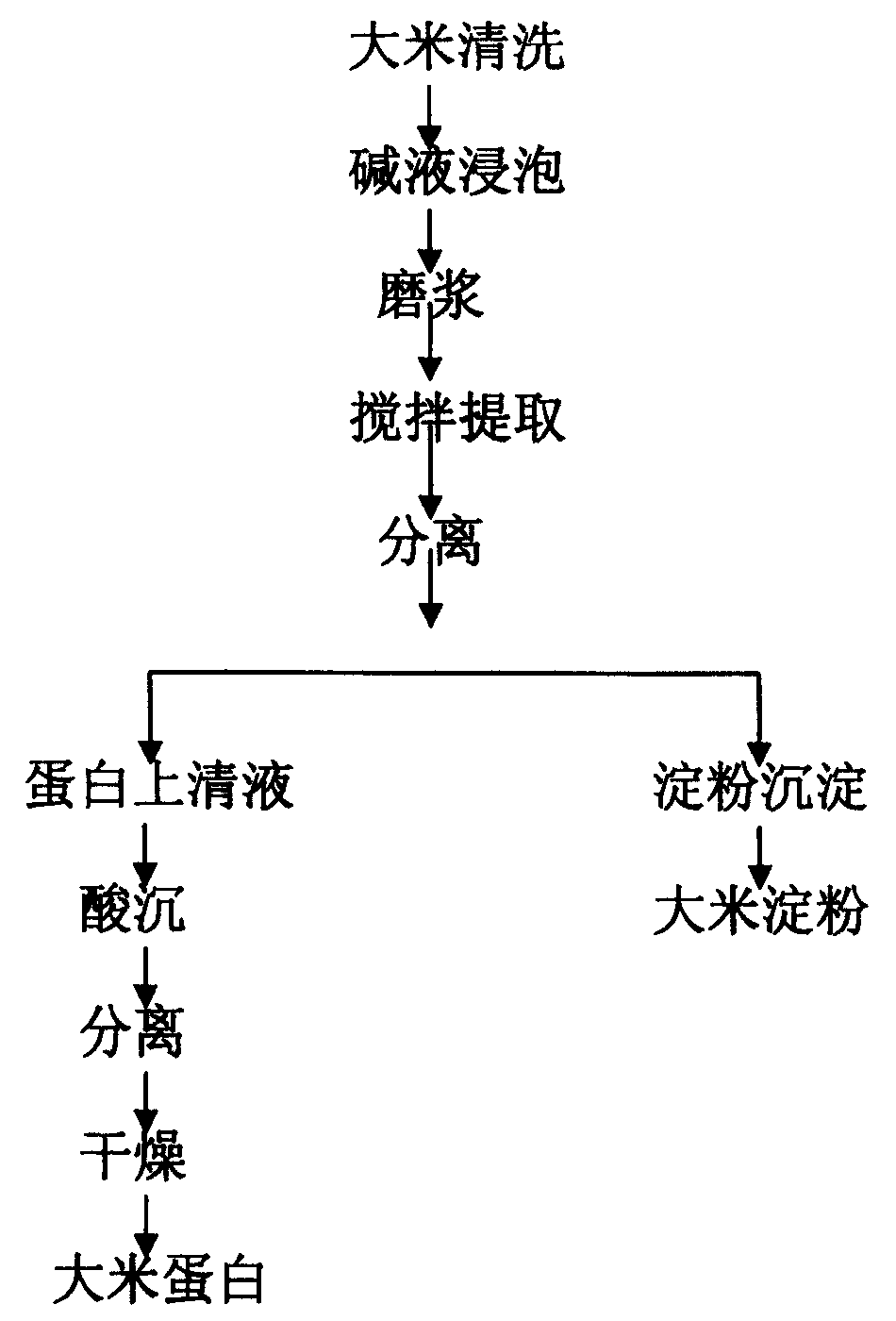

Method for extracting rice protein by alkaline process

A rice protein, alkaline extraction technology, applied in the direction of plant peptides, peptide sources, etc., can solve the process parameters such as NaOH concentration extraction time, solid-liquid ratio is not reasonable, there is no industrial production method of alkaline extraction of rice protein, alkali It is difficult to apply the method to industrial production and other problems to achieve good extraction effect, low cost and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Get 500 grams of early indica rice, add 2.58 liters of 0.09mol / L NaOH solution, soak for 2 hours and refine to 100 mesh or more and stir for 2 hours to keep the solution pH=11. Centrifuge at a high speed of 4000 rpm for 15 minutes in a centrifuge to collect the protein supernatant and starch precipitate. Add 0.09 mol / L hydrochloric acid to the protein supernatant, and measure the pH to 5.5 with an acidity meter while stirring while adding. Add 0.09mol / L NaOH solution to the precipitate after acid precipitation to make it neutral, then centrifuge at a high speed of 4000 rpm for 15 minutes, discard the supernatant, and collect the protein precipitate. The precipitation is washed with water and then the centrifugation is repeated to obtain rice protein. Dilute the starch precipitate with water and stir evenly, then centrifuge to take the supernatant, repeat the steps of acid precipitation and centrifugation, and part of the rice protein and rice starch can be obtained. P...

Embodiment 2

[0039] Get 500 grams of early indica rice, add 3 liters of 0.09mol / L NaOH solution, soak for 2.5 hours and grind to more than 100 mesh and stir for 2.5 hours to keep the solution pH=11. Centrifuge at a high speed of 4000 rpm for 15 minutes in a centrifuge to collect the protein supernatant and starch precipitate. Add 0.09 mol / L hydrochloric acid to the protein supernatant, and measure the pH to 5.0 with an acidity meter while stirring while adding. Add 0.09mol / L NaOH solution to the precipitate after acid precipitation to make it neutral, then centrifuge at a high speed of 4000 rpm for 15 minutes, discard the supernatant, and collect the protein precipitate. The precipitation is washed with water and then the centrifugation is repeated to obtain rice protein. Dilute the starch precipitate with water and stir evenly, then centrifuge to take the supernatant, repeat the steps of acid precipitation and centrifugation, and part of the rice protein and rice starch can be obtained. ...

Embodiment 3

[0041] Get 500 grams of early indica rice, add 3.5 liters of 0.09mol / L NaOH solution, soak for 3 hours and grind to more than 100 mesh and stir for 3 hours to keep the solution pH=11. Centrifuge at a high speed of 4000 rpm for 15 minutes in a centrifuge to collect the protein supernatant and starch precipitate. Add 0.09 mol / L hydrochloric acid to the protein supernatant, and measure the pH to 4.5 with an acidity meter while stirring while adding. Add 0.09mol / L NaOH solution to the precipitate after acid precipitation to make it neutral, then centrifuge at a high speed of 4000 rpm for 15 minutes, discard the supernatant, and collect the protein precipitate. The precipitation is washed with water and then the centrifugation is repeated to obtain rice protein. Dilute the starch precipitate with water and stir evenly, then centrifuge to take the supernatant, repeat the steps of acid precipitation and centrifugation, and part of the rice protein and rice starch can be obtained. P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com