Method and device for continuously extracting starch in corn fiber skin by enzymic method

A corn fiber and continuous technology, applied in the field of enzymatic continuous extraction of starch from corn fiber husks, can solve the problems of high energy consumption, impossibility of industrial application, high processing cost, etc., achieve high concentration, good application and promotion prospects, and high extraction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

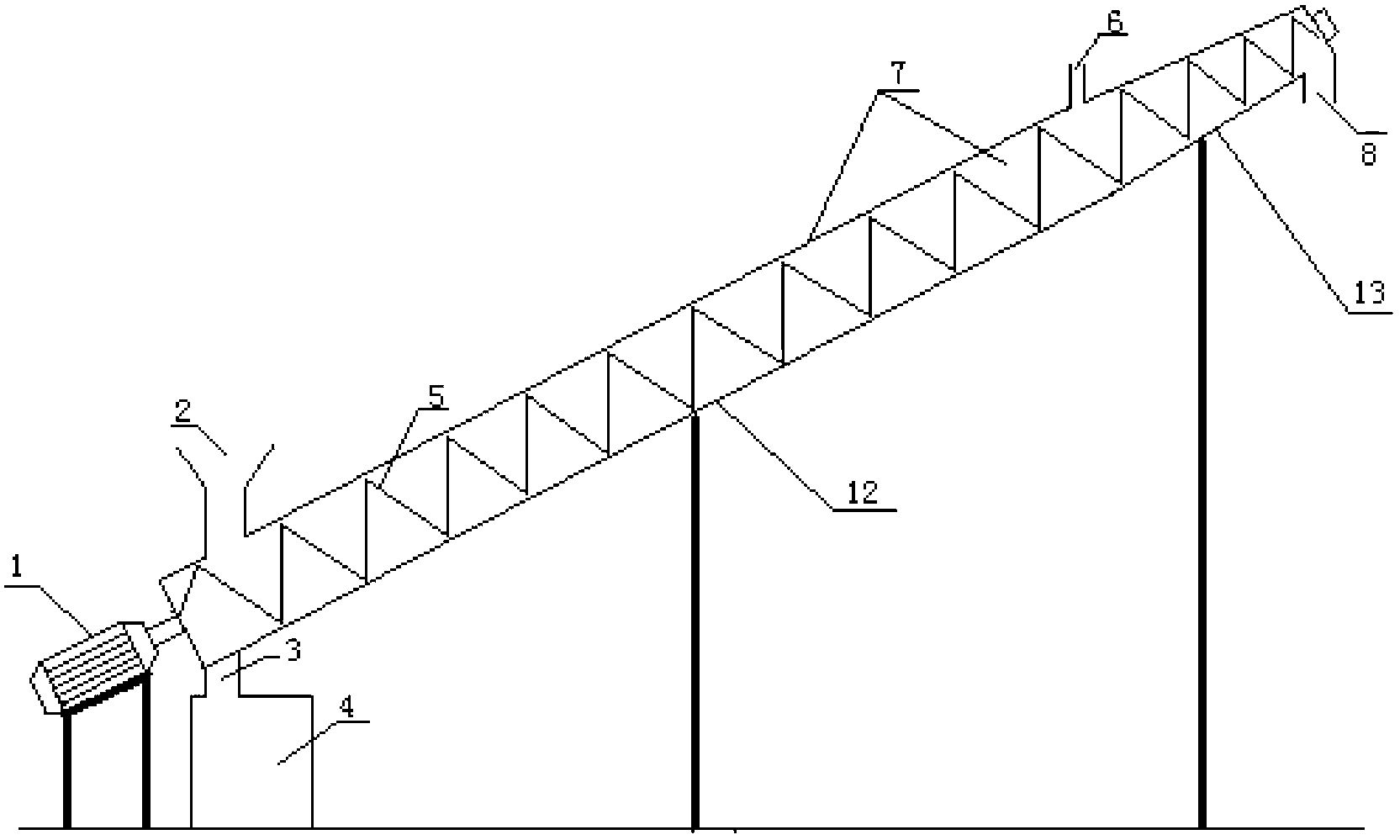

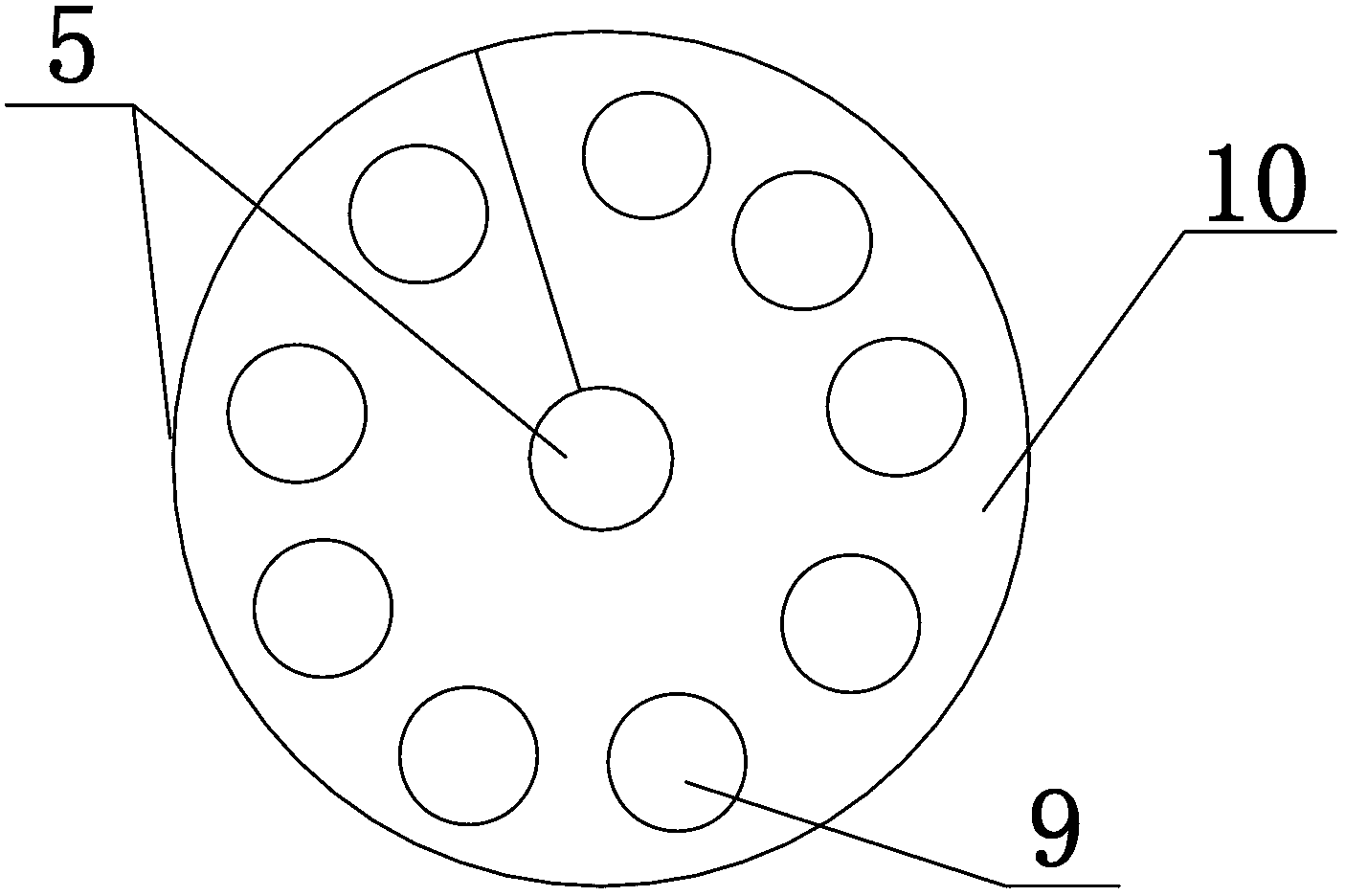

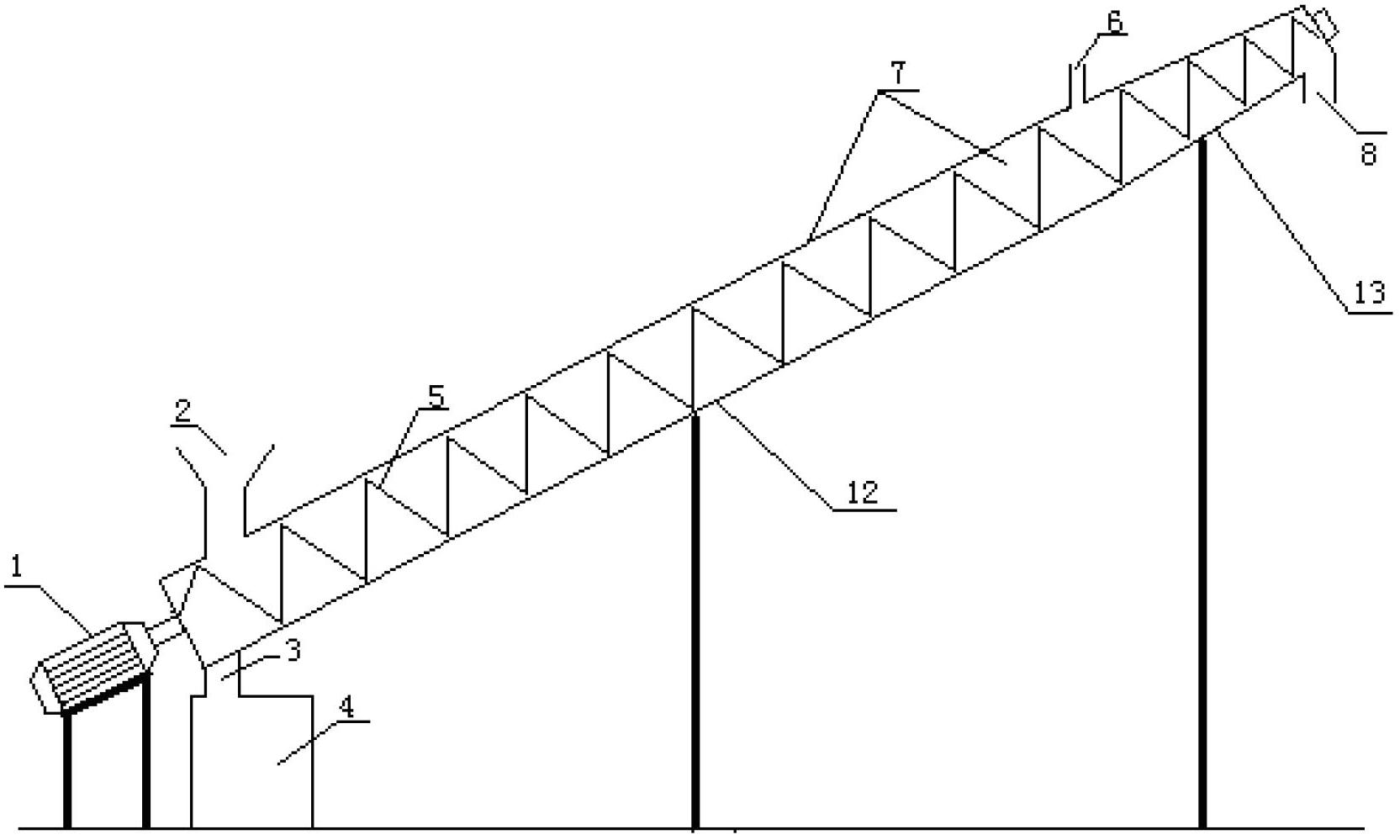

[0039]A device for continuously extracting starch in corn fiber husks by enzymatic method, comprising a frequency conversion speed regulation motor 1, an extraction cylinder 7, a screw conveying rod 5 and a storage tank 4, the extraction cylinder 7 is an inclined airtight cylinder, and the spiral The conveying rod 5 is arranged in the extraction cylinder 7, and one end of the screw conveying rod 5 is connected with the frequency conversion speed regulating motor 1 arranged outside the lower end of the extracting cylinder through a connecting rod. The length of the extraction cylinder is adapted to the inner diameter of the cylinder; the upper surface of the lower end of the side wall of the extraction cylinder 7 is provided with a feed inlet 2, and the lower surface of the lower end of the side wall of the extraction cylinder 7 is provided with a hydrolyzate outlet 3, and the hydrolyzate outlet 3 is connected to the storage tank 4 Through, a filter screen is arranged between th...

Embodiment 2

[0043] Utilize the device described in embodiment 1 to carry out the method for enzymatic continuous extraction of starch in corn fiber husks, the steps are as follows:

[0044] (1) Prepare an extract with a temperature of 70-72°C, a pH of 6, and 300 U / L of mesophilic α-amylase;

[0045] (2) According to the feed rate of 113.6kg / h (dry weight: 100kg / h) of corn fiber husks, add corn fiber husks to the extraction cylinder through the feed port, and the corn fiber husks are from the bottom of the extraction cylinder to the top of the extraction cylinder Movement, according to the liquid addition speed of 400L / h, add the extract prepared in step (1) to the extraction cylinder through the extraction liquid inlet, the extraction liquid moves from the top of the extraction cylinder to the bottom of the extraction cylinder, and passes through the corn fiber husk and the extraction liquid The reverse motion of contacting carries out the hydrolysis of the starch in the corn fiber husk, ...

Embodiment 3

[0052] Utilize the device described in embodiment 1 to carry out the method for enzymatic continuous extraction of starch in corn fiber husks, the steps are as follows:

[0053] (1) Prepare an extract solution with a temperature of 88-90°C, a pH of 6, and 900 U / ml of high-temperature α-amylase;

[0054] (2) According to the feed rate of 227.3kg / h (dry weight: 200kg / h) of corn fiber husks, add corn fiber husks to the extraction cylinder through the feed port, and the corn fiber husks are from the bottom of the extraction cylinder to the top of the extraction cylinder Movement, according to the liquid feeding speed of 1200L / h, add the extract prepared in step (1) to the extraction cylinder through the extraction liquid inlet, the extraction liquid moves from the top of the extraction cylinder to the bottom of the extraction cylinder, and passes through the corn fiber husk and the extraction liquid The reverse motion of the contact is carried out to hydrolyze the starch in the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Upper mouth diameter | aaaaa | aaaaa |

| Lower mouth diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com