Dewatering treatment device for low-concentration pulp in pipes and treatment method of dewatering treatment device

A treatment device and low concentration technology, which is applied in the concentration separation and dehydration treatment device and pipeline transportation field, can solve the problems of high treatment process cost, failure to meet the pipeline transportation and dehydration process, and low pulp concentration, so as to save treatment cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

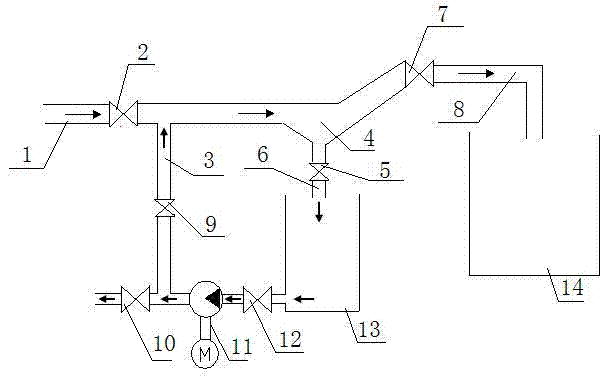

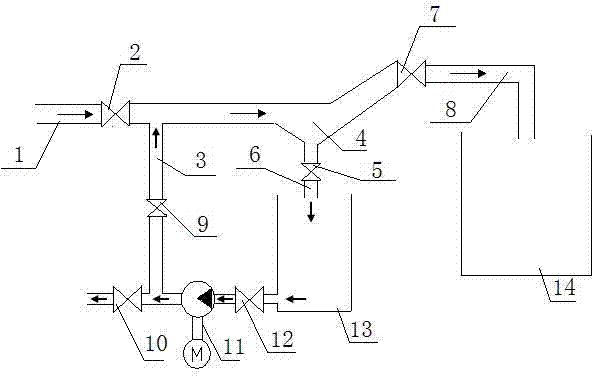

[0022] Combine below figure 1 , the present invention is further described:

[0023] The input end of the slurry flow sedimentation device 4 is directly connected to the low-concentration pulp inlet pipeline 1 and the circulation sedimentation pipeline 3, which are separated by the inlet pipeline isolation valve 2 and the second outlet valve 9 of the underflow pump respectively. There is one slurry flow sedimentation device 4 The output port is directly connected to the pool 14 through the pipeline 8 entering the pool, and the middle is isolated by the regulating valve 7 entering the pool, and the output port at the lower end of the slurry flow sedimentation device 4 is connected to the slurry stirring tank through the pipeline 6 entering the slurry stirring tank 13. In the middle, use the adjustment valve 5 to enter the stirring tank to isolate. The slurry in the slurry stirring tank 13 enters the underflow pump 11 through the inlet valve 12 of the underflow pump, and enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com