Spraying irrigation spray nozzle capable of automatic rotary spraying

A technology of automatic rotation and sprinkler head, which is applied in the direction of spraying devices and spraying devices with movable outlets, which can solve the problems of flood irrigation, sprinkling irrigation instability and unevenness increase, and achieve water saving, uniform force, and unevenness. easy pouring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific examples.

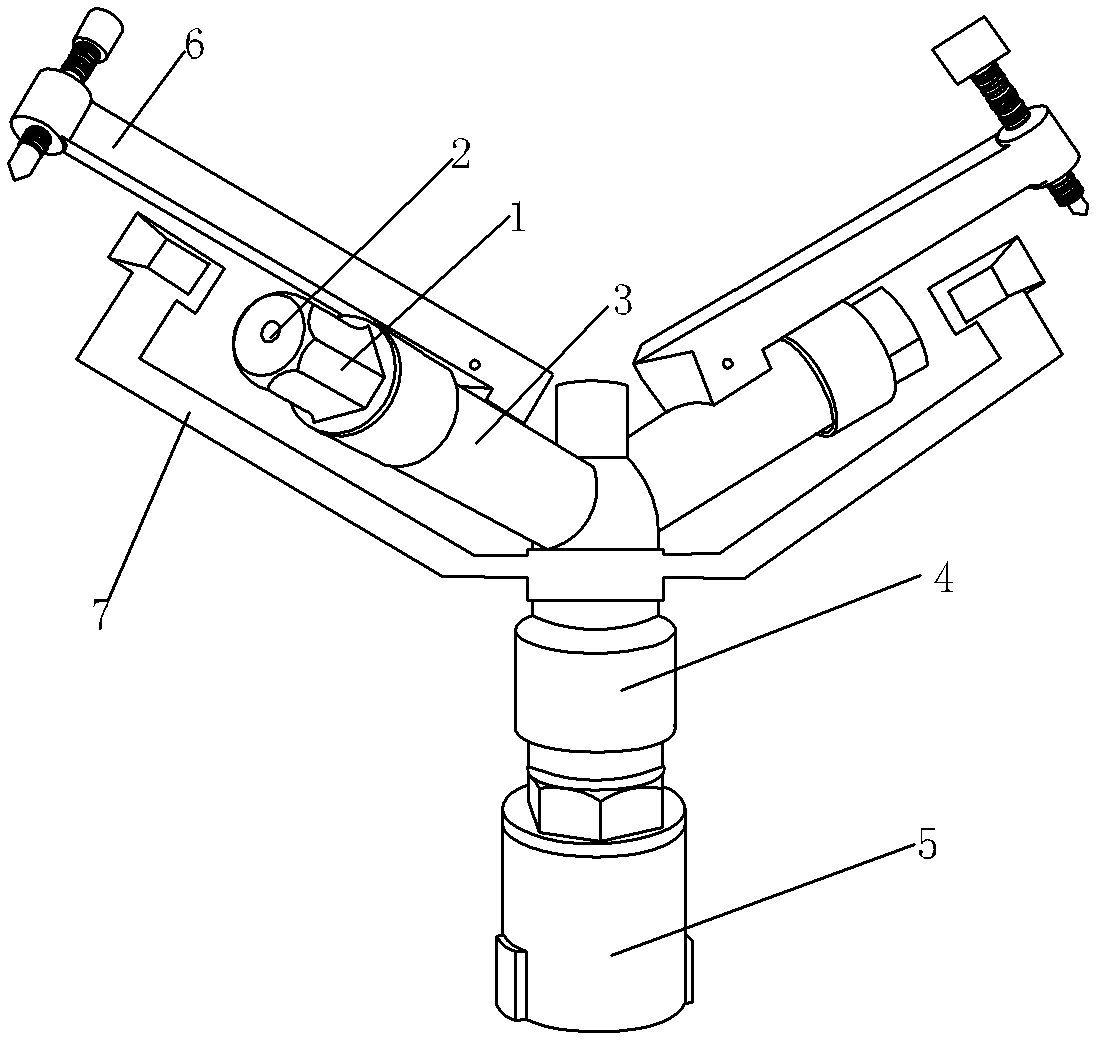

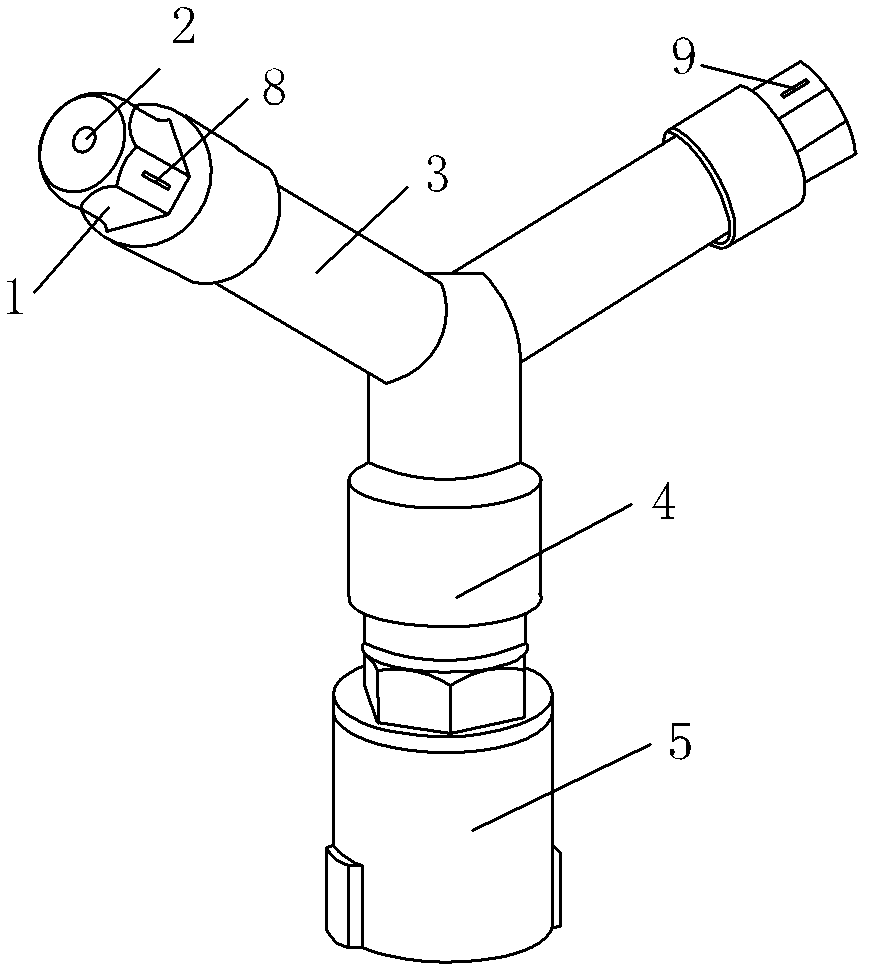

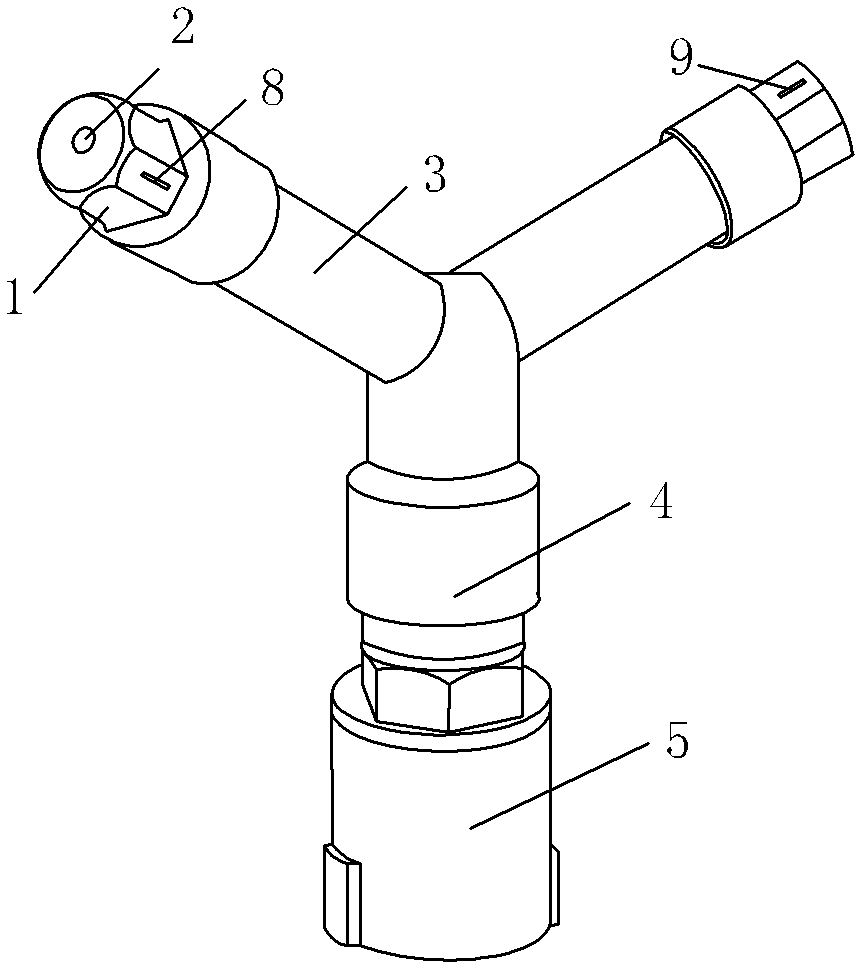

[0017] figure 2 Schematic diagram of the sprinkler nozzle for automatic rotary spraying of the present invention. The sprinkler nozzle saves the rocker arm 7 and the water distributor 6, and the structure is greatly simplified. Two sprinkler main bodies 3 are fixed on the rotating body 4 at an angle of 135-150 degrees, so that the sprinkling angle is between 30-45 degrees. Two shower head main bodies 3 fix the upper end of the rotating body 4, and the two shower heads 1 at the front end of the shower head main body 3 are respectively provided with radial main nozzles 2, and the diameter of the main nozzles 2 is between 2.5-5.0 mm.

[0018] Sub-nozzles 8 and 9 are respectively arranged on the sides of the two spray heads 1, the direction of the two sub-nozzles 8 and 9 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com