Automatic blanking device for steel pipe

An automatic blanking and steel pipe technology, which is applied in the field of steel pipe manufacturing, can solve the problems of low work efficiency and consumption of workers' physical strength, and achieve the effects of high work efficiency, saving human resources and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

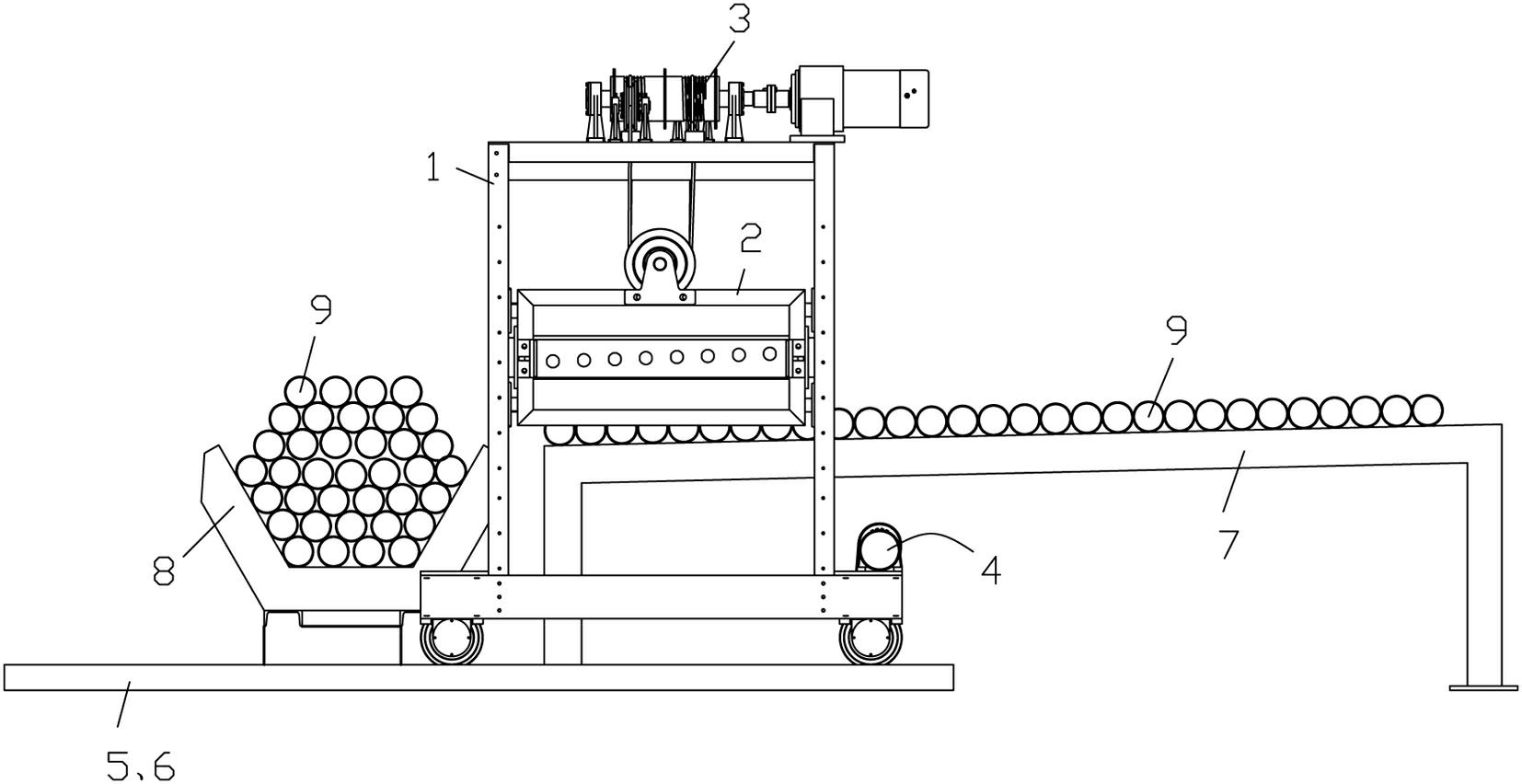

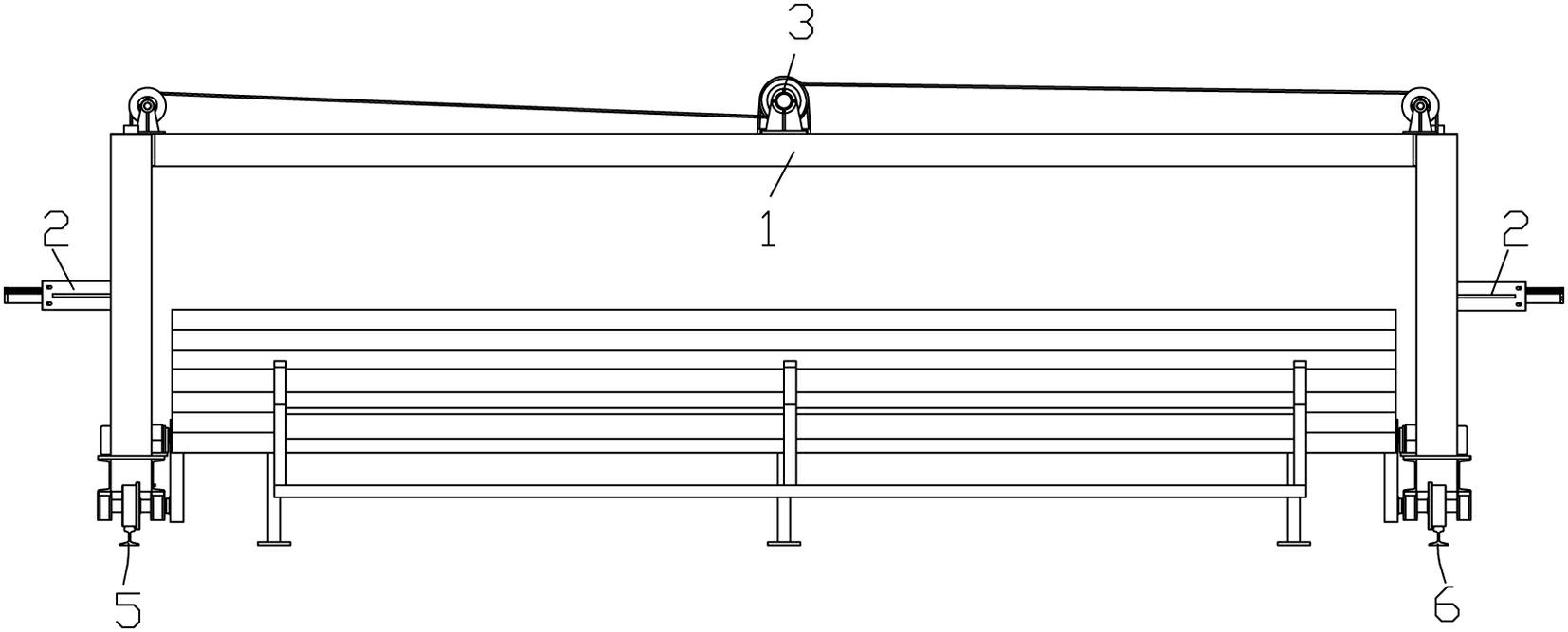

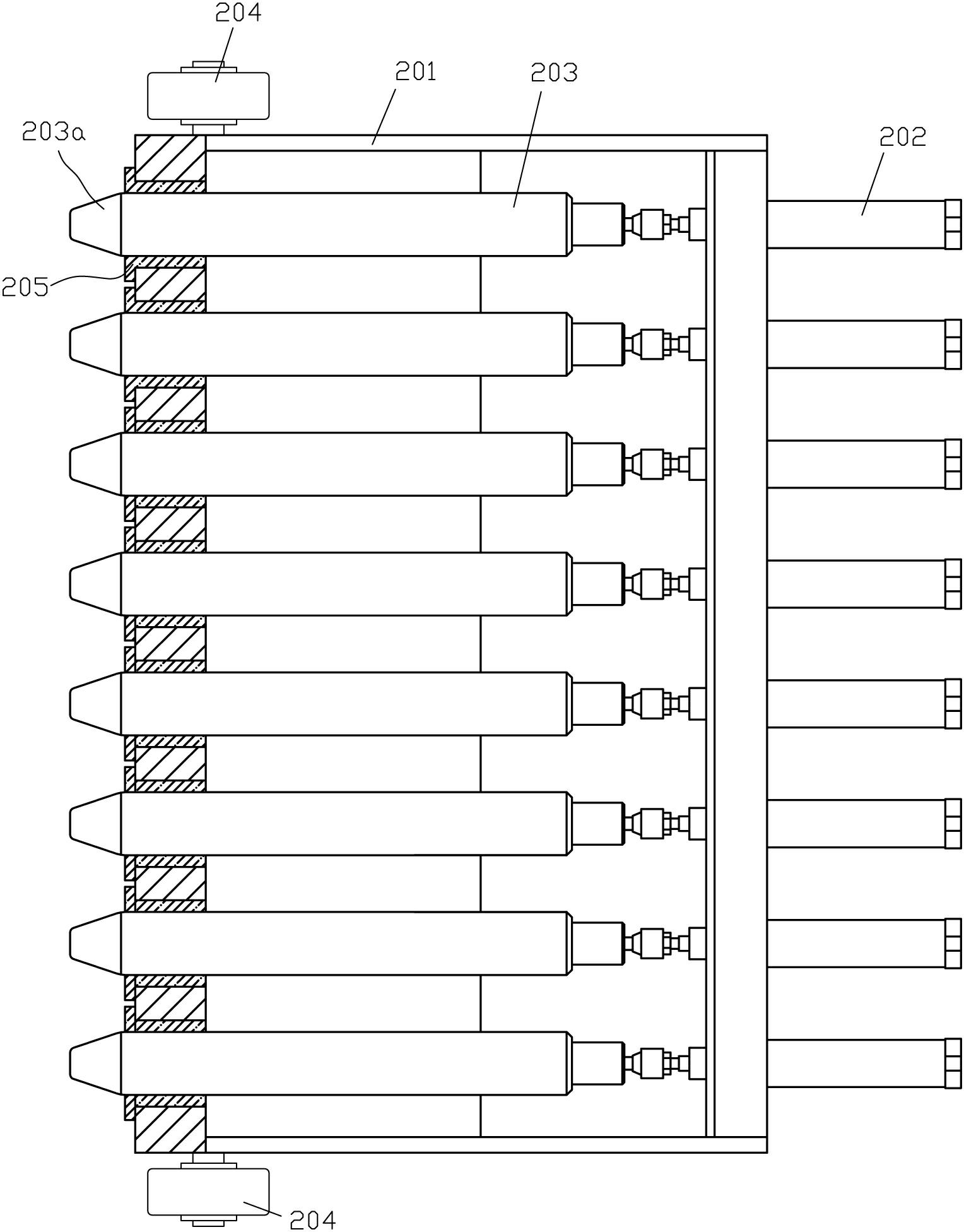

[0031] Examples, see attached figure 1 , 2 , 3, 4, an automatic steel pipe blanking equipment, including a beam 1, said beam 1 includes a beam 101, on which a left frame 102, a right frame 103, a beam 101, a left frame 102 and The right frame 103 can be welded by channel steel or square steel pipes. In order to increase the structural strength between the beam 101 and the left frame 102 and the right frame 103, reinforcing ribs can be welded or screwed at the intersection. The steel pipe grabbing mechanism 2 is installed on 103 to grab the steel pipe. That is to say, there are two steel pipe grabbing mechanisms 2 installed on the left frame 102 and the right frame 103 respectively. The steel pipe grabbing mechanism 2 includes a movable frame 201 A plurality of telescopic mechanisms 202 are installed in the movable frame 201. Generally, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com