Mechanical water-break automatic close valve

An automatic closing, mechanical technology, applied in mechanical equipment, valve details, valve devices, etc., can solve the problems of valve installation angle with special requirements, easy to malfunction, etc., to achieve the effect of low cost, accurate action and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

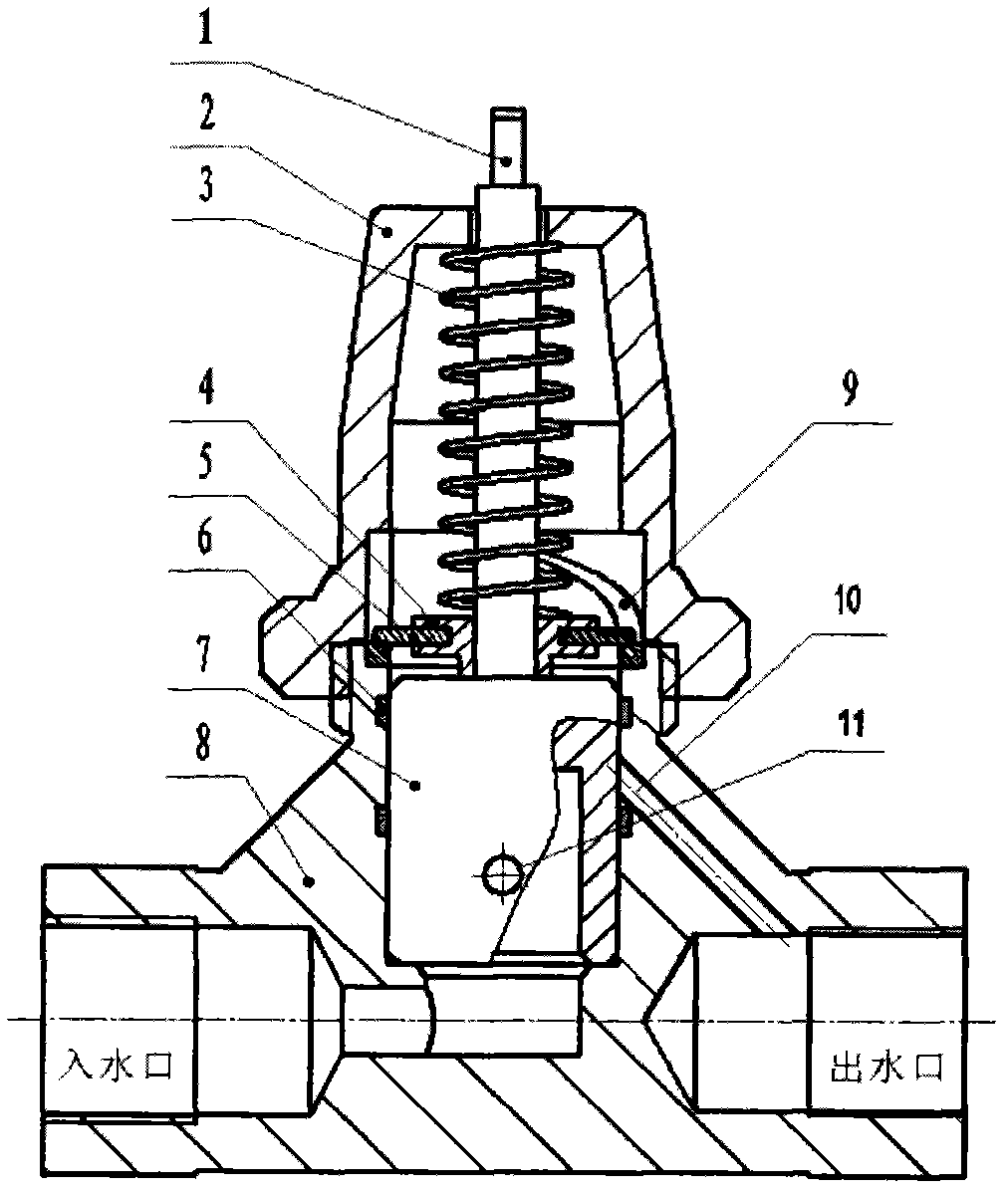

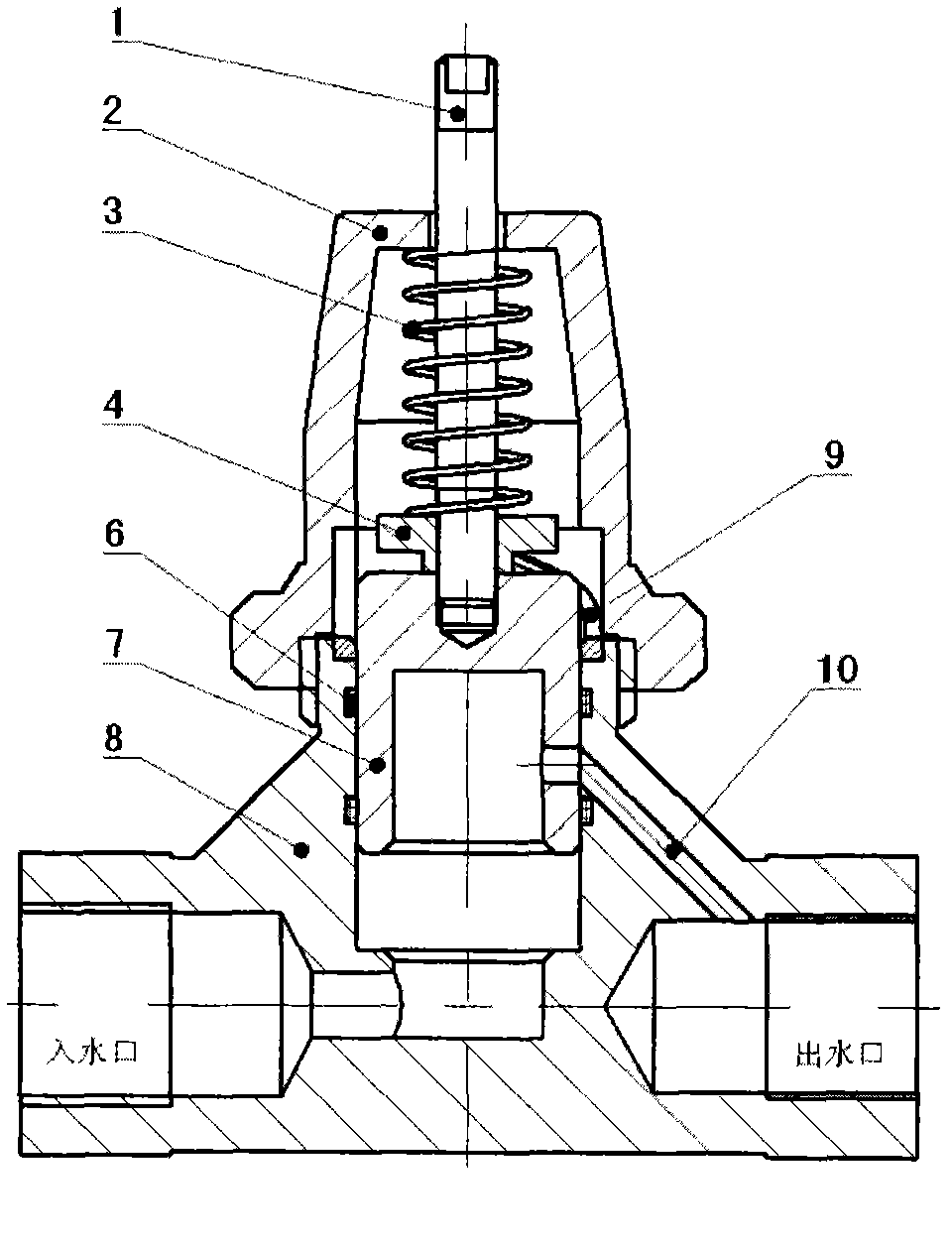

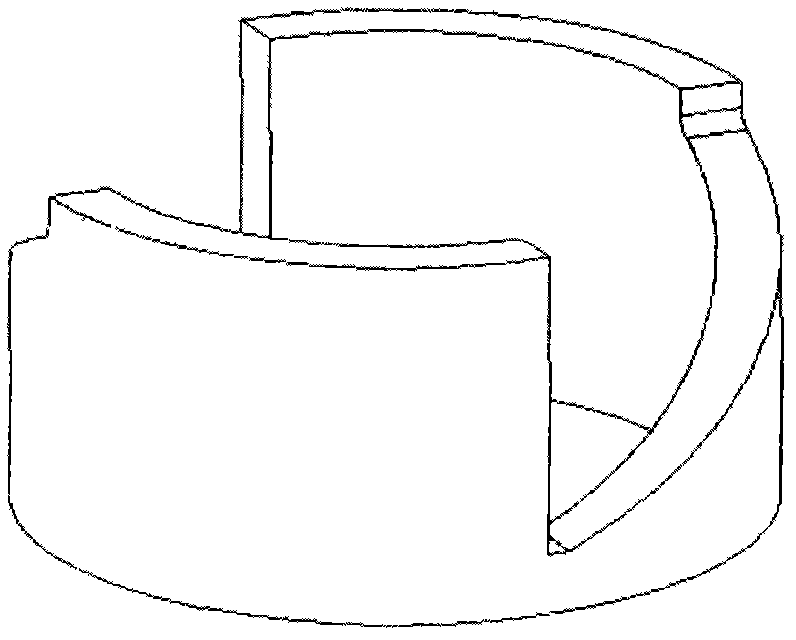

[0020] see figure 1 , a mechanical water-cutting automatic closing valve, including a valve stem 1, a valve body 8, a valve cover 2, a valve core 7, a compression spring 3, an inner cylindrical cam 11, an O-ring 6, a slider 5 and a gasket 4, The valve stem 1 is installed in the valve cover 2, the upper end of the valve stem 1 passes through the upper center of the valve cover 2, and the lower end of the valve stem 1 passes through the slider 5 and is threaded with the valve core 7; the valve cover 2 and the valve body 8 Threaded connection, the valve core 7 is installed in the cavity of the valve body 8, and the inner wall of the cavity of the valve body 8 is provided with 1 to 3 sealing grooves, and the sealing grooves are respectively equipped with O-rings 6, which are installed on the valve stem 1 One end of the compression spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com